Product processing production line

A production line and product technology, applied in meat processing, poultry processing, comprehensive factory control, etc., can solve problems such as restricting the development of processing industry, labor-intensive labor, inconvenient unified management, etc., to reduce labor intensity, reduce labor, and ensure The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

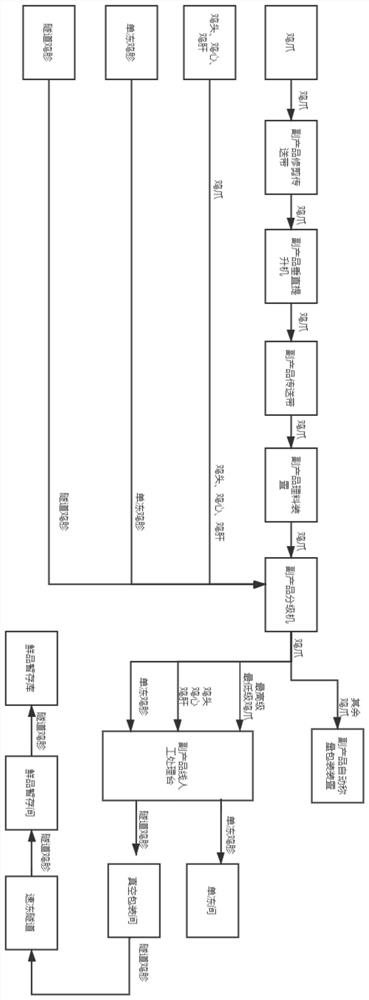

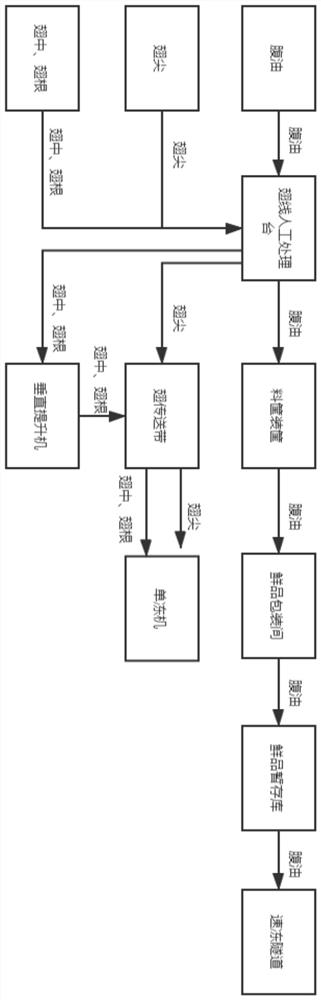

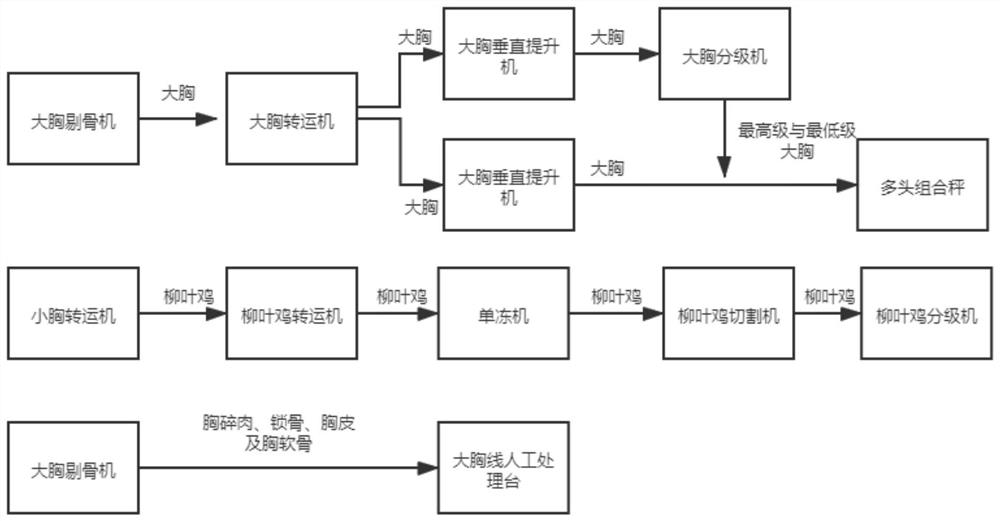

[0064] A product processing production line, the production line includes a cutting equipment line, a by-product line, a wing line, a large chest line, a neck line, a leg line, a leg meat line, a skeleton line, a tunnel back line, and a material basket arranged in each production line transfer line;

[0065] It also includes an intelligent system for regulating each production line. The intelligent system includes a production management module and a personnel management module. The production management module includes a material basket, an information monitoring device, a rejecting device, a host computer and a database. On the basket transfer line, the material basket includes a basket, and an RFID information card is installed on the basket, and the RFID information card stores a basket information group, and the information monitoring point is used to identify the RFID information card, read The information content is sent to the upper computer, and the upper computer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com