Fully-automatic car washer profiling follow-up air drying device

A technology of air drying device and car washing machine, which is applied in the direction of vehicle exterior cleaning devices, etc., which can solve the problems of wasting energy, uneven blowing effect of car washing, and different blowing effects, etc., and achieve the effect of improving the blowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

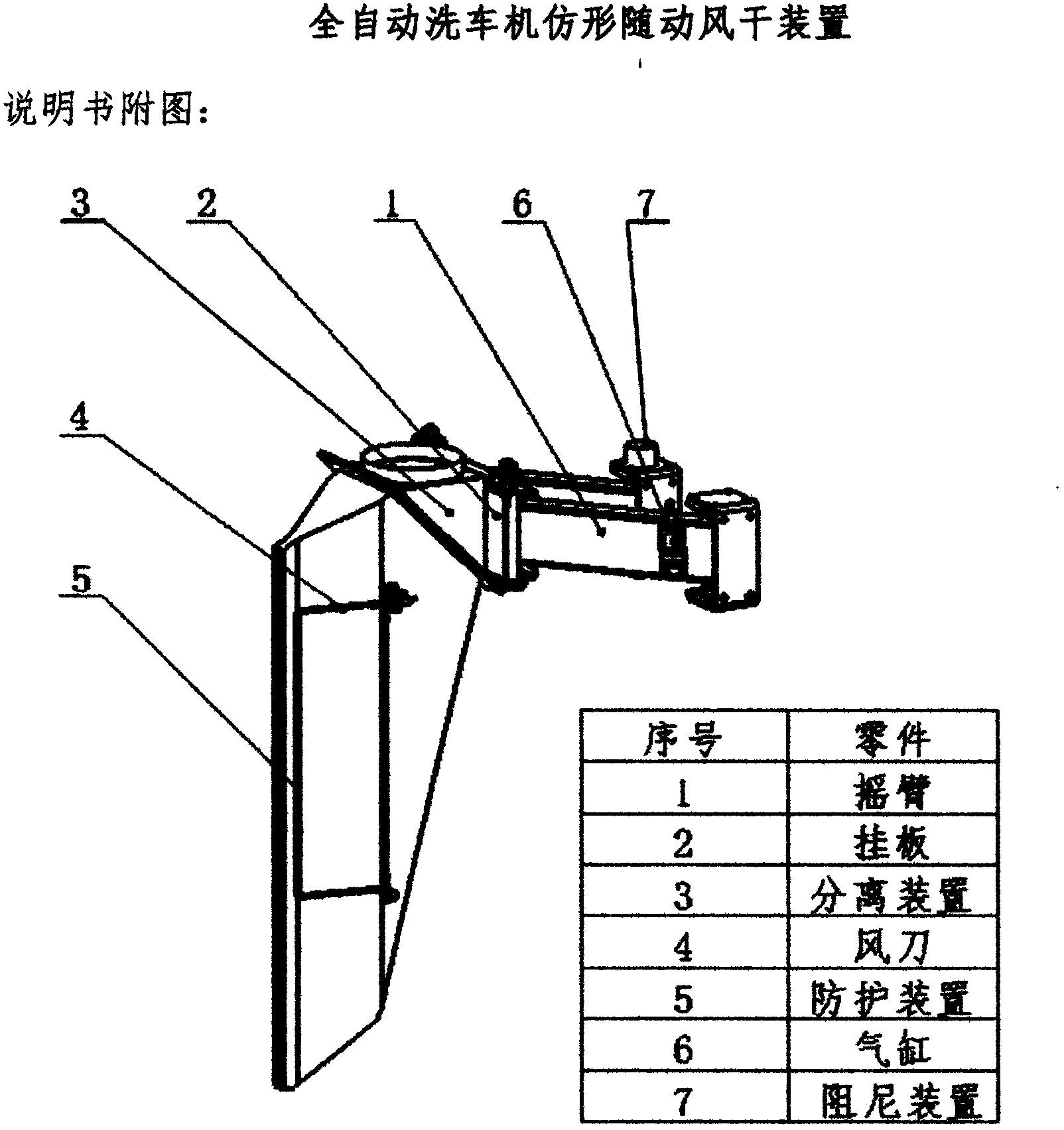

[0008] The automatic car washing machine profiling follow-up air-drying device as shown in the accompanying drawing, its structure is to arrange a parallelogram double rocker link mechanism (1), and keep the horizontal position, the upper position of the double rocker arm link mechanism (1) is Hanging plate (2) is fixed, blower (3,4) is fixed on the hanging plate 2, damping device 7 is added at the rotating shaft place of double rocker arm link mechanism (1), in double rocker arm link mechanism (1 ) is provided with a cylinder 6 on the other rocker lever, a guard 5 is set on the other side of the blower (3, 4), and an air knife (4) is set on the guard 5.

[0009] The parallelogram connecting rod mechanism should maintain a horizontal position, and the space constraints and the adaptable range of the vehicle should be considered in detail; the thrust and stroke of the cylinder should be correctly set; a damping device should be added to the rotating shaft of the connecting rod m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com