Printing press dry box

A technology for drying ovens and printing machines, applied to printing machines, printing, general parts of printing machinery, etc., can solve the problems of high energy consumption and low efficiency of hot air utilization, and achieve energy saving, good printing effect, and stable printing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

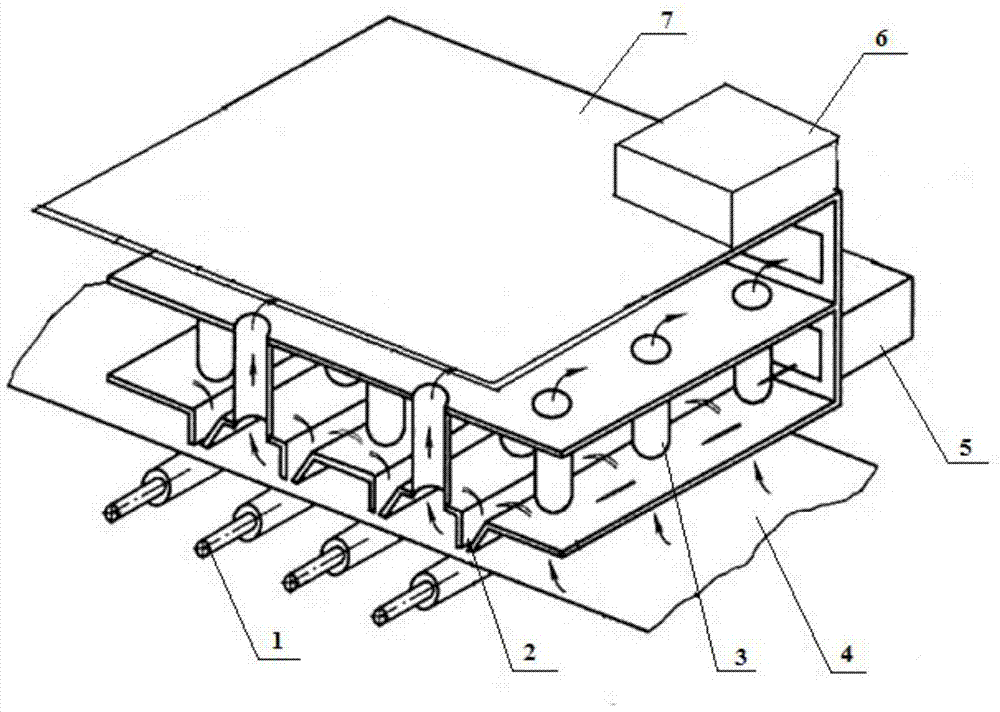

[0012] Such as figure 1 As shown, a printing machine drying box includes an air inlet 5 installed on the side wall of the drying box and an air outlet 6 installed on the top cover 7 of the drying box. There are a plurality of air nozzles 2, the air nozzles 2 are facing the printing material 4 above the guide roller assembly 1, and a plurality of return air ducts 3 are arranged on the middle partition of the drying box, and the return air duct 3 The outlet is towards the top cover 7 of the drying box.

[0013] The air nozzle 2 of the present invention faces the printing material 4 above the guide roller assembly 1, the air nozzle 2 is V-shaped and can blow hot air to the printing material 4 more evenly, ensuring clear patterns of printed matter and uniform ink transfer; the air inlet 5 is installed On the side wall of the drying oven, the air outlet 6 is installed on the top cover of the drying oven, and the air circulation in the oven is smooth, which not only reduces the los...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com