A pot for heating cooking oil

A technology of cooking oil and cooking utensils, applied in the field of miniaturized energy-saving electric heating cooking utensils. Heating characteristics and temperature maintenance characteristics, the effect of overcoming difficult operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

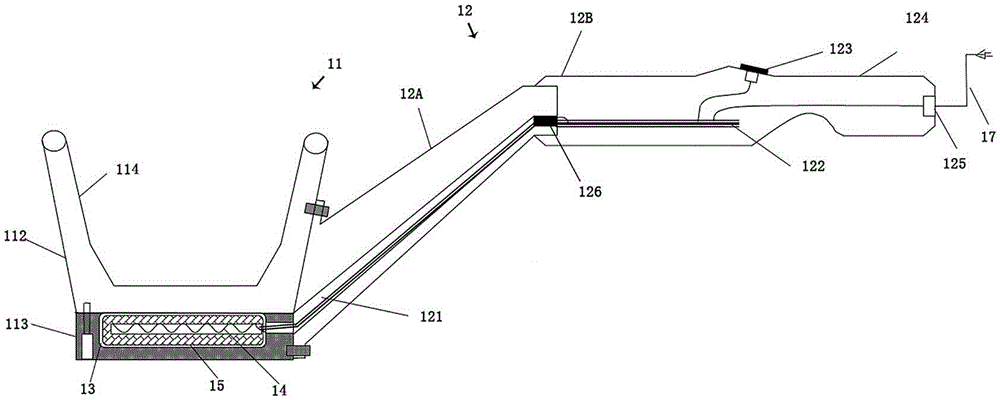

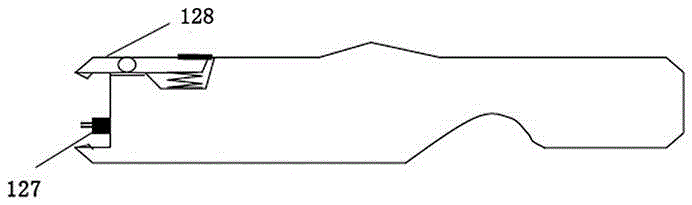

[0030] exist figure 1 The first embodiment of the pot for heating edible oil according to the present invention is shown in , this embodiment specifically includes: a pot body 11, a handle portion 12 and a power cord 17, the pot body 11 includes a pot body upper part 112 And pot body lower part 113, form cavity 13 between described pot body upper part 112 and pot body lower part 113, described pot body upper part 112 is used to accommodate the edible oil to be heated, and its inner surface uses non-stick pan coating 114 or will Its inner surface is treated as a non-stick pan surface, and the non-stick pan coating 114 can be selected from Teflon coating, ceramic coating, etc.; the capacity of the upper part of the pan body 112 is less than or equal to 0.5L; the cavity 13 is provided with an electric heating part 14 And heat-conducting insulating material 15; the pot also includes a temperature control unit 16 for controlling the working state of the electric heating part 14. I...

no. 2 approach

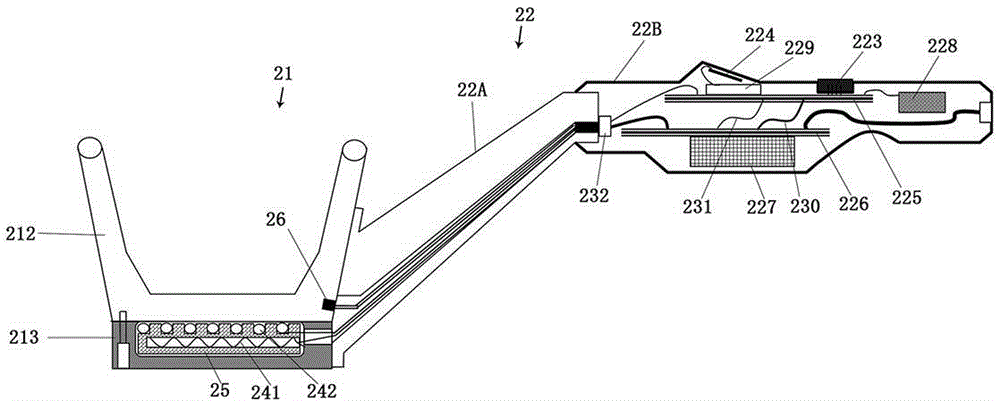

[0038] exist image 3 shows the second embodiment of the pot for heating edible oil according to the present invention, this embodiment specifically includes: a pot body 21, a handle 22 and a power cord (not shown in the figure), the pot body 21 includes a pot body upper part 212 and a pot body lower part 213, a cavity is formed between the pot body upper part 212 and the pot body lower part 213, and the pot body upper part 212 is used to accommodate edible oil to be heated, and its inner surface is made of non-stick The pot coating or its inner surface is treated as a non-stick pan surface. The non-stick pan coating can be Teflon coating, ceramic coating, etc.; the capacity of the upper part 212 of the above-mentioned pot body is less than or equal to 0.5L; the electric heating is installed in the cavity Part 24 and heat-conducting insulating material 25; the pot also includes a temperature control unit 26 for controlling the working state of the electric heating part 24. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com