Method for optical cable splicing with communication service uninterrupted and fiber coiling box

A technology for communication services and fiber reels, which is applied in the field of communication maintenance, can solve problems such as long welding time and affect the safe operation of power lines, and achieve the effect of enhancing corporate image, improving work ability, management level, and improving level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

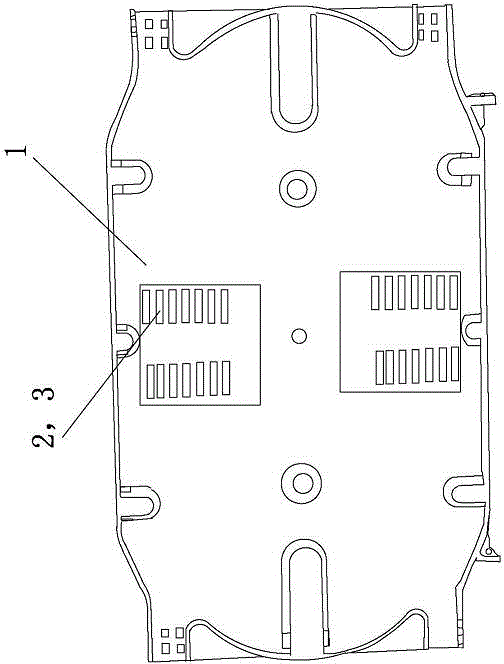

[0022] Such as figure 1 shown.

[0023] A method for splicing optical cables without interrupting communication services, comprising the following steps:

[0024] First, use the existing mature optical fiber fault location method to determine the location of the optical fiber fault;

[0025] Secondly, by releasing the coiled wire on the auxiliary pole at the fault location for at least one meter so that the sheath of the optical fiber at the fault location can be stripped at least 1-2 meters in length, the loose sleeve where the faulty optical fiber is located is determined according to the color or number Tube;

[0026] Thirdly, the loose tube that has not failed is placed in the fixed groove that matches the outer diameter of the loose tube added in the fiber box and positioned;

[0027] Fourth, use a slotting machine to peel off the loose tube where the faulty optical fiber is located. The length of the peeled off should be greater than the length of at least one coil in...

Embodiment 2

[0031] Such as figure 1 shown.

[0032] A disk fiber box for uninterrupted optical cable fusion splicing, which is characterized in that it includes a box body 1, and is characterized in that the box body 1 is provided with a fixing groove patch 2 for fixing a loose tube and a fiber core for fixing The fiber core coiling slot patch 3, the fixed slot patch 2 and the fiber core coiling slot patch 3 are pasted in different boxes 1 or stacked in the same box body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com