Optical method based high-speed aircraft hot surface full-field deformation measuring device

A high-speed aircraft and optical method technology, which is applied in the field of full-field deformation measurement of the thermal surface of high-speed aircraft, can solve problems such as aliasing interference of high-temperature light sources, and achieve good test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

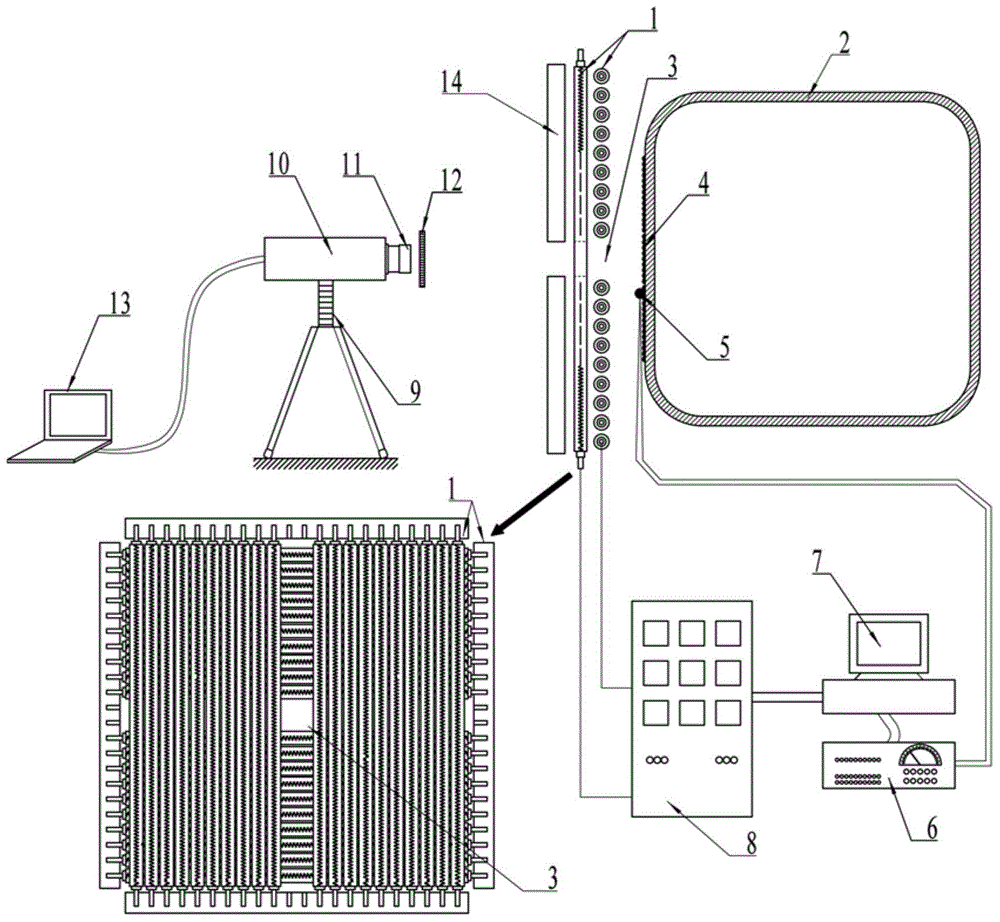

[0032] like figure 1 As shown, the present invention consists of a double-layer quartz lamp heating array 1, a high-speed aircraft thin-walled shell 2, a square light-transmitting window 3, speckle particles 4, a thermocouple sensor 5, a signal amplifier 6, a temperature control computer 7, a driving power supply 8, The adjustment bracket 9, the CMOS camera 10, the lens 11, the narrow bandpass optical filter 12, the image processing computer 13 and the light high temperature ceramic plate 14 are composed. The infrared radiant light emitted by the double-layer quartz lamp heating array 1 irradiates the surface of the thin-walled shell 2 of the high-speed aircraft to simulate the thermal environment in flight, and the thermocouple sensor 5 is installed on the surface of the thin-walled shell 2 of the high-speed aircraft, and the thermocouple sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com