Porous silicon-based non-labelling real-time online detection method for cholera toxins

A technology for cholera toxin and porous silicon, which is used in the measurement of phase-influenced properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

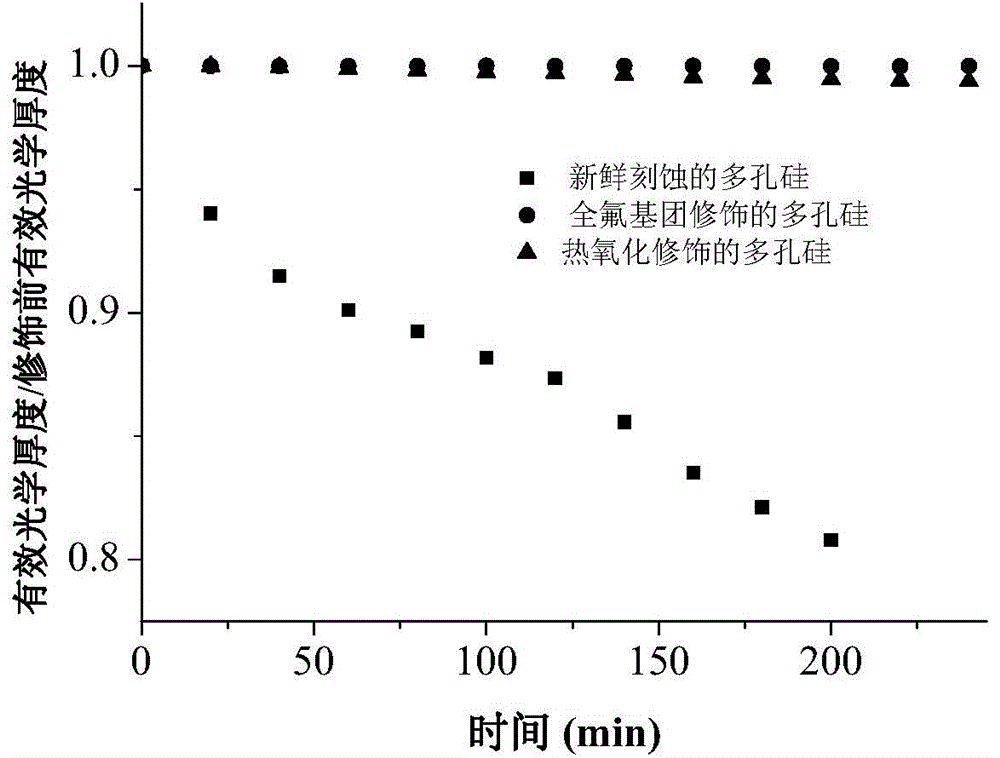

[0040] Hydrophobicity and stability verification of the film of embodiment 1

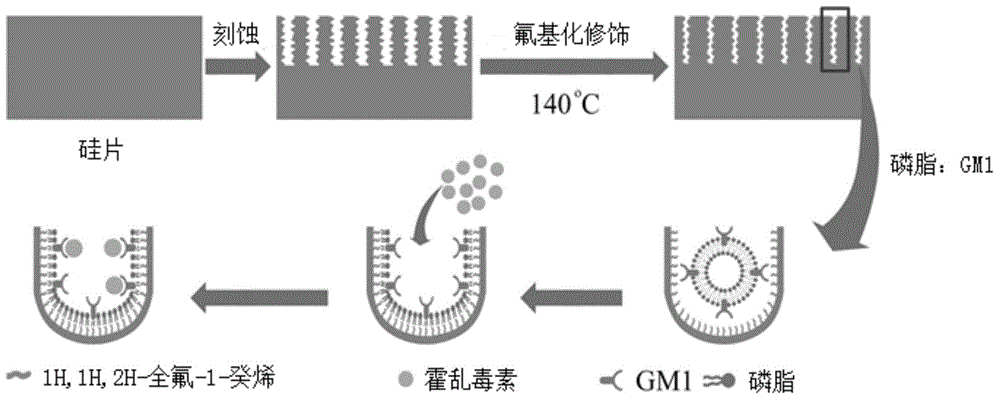

[0041] (1) First, silicon wafers were prepared by electrochemical etching to prepare porous silicon. The etching solution was hydrofosic acid: absolute ethanol (volume ratio 3:1), the current sensitivity was 486mA / cm2, and the etching time was 10s.

[0042] (2) Hydrophobic modification of silicon surface by 1H, 1H, 2H-perfluoro-1-decene at 140°C under nitrogen protection for 2 hours. Hydrophobic modified silicon wafers were obtained.

[0043] (3) The hydrophobically modified silicon wafer is fixed on the bottom of the polycarbonate flow cell, and the Y-shaped optical fiber is perpendicular to the surface of the flow cell. The reflection interference spectrum is obtained through the optical fiber, and a data is recorded every 6 seconds. The Liye is transformed into a reflection peak spectrum, with time as the axis of abscissa and intensity of the reflection spectrum as the axis of ordinate, and is ...

Embodiment 2

[0048] Steps (1)-(3) are the same as in Example 1,

[0049] (4) Liposome-monosialoganglioside nano-mixture was prepared with a liposome extruder; the molar ratio of monosialoganglioside and liposome microspheres was 1:40, and extruded through a pore size of 50nm of polycarbonate film 21 times.

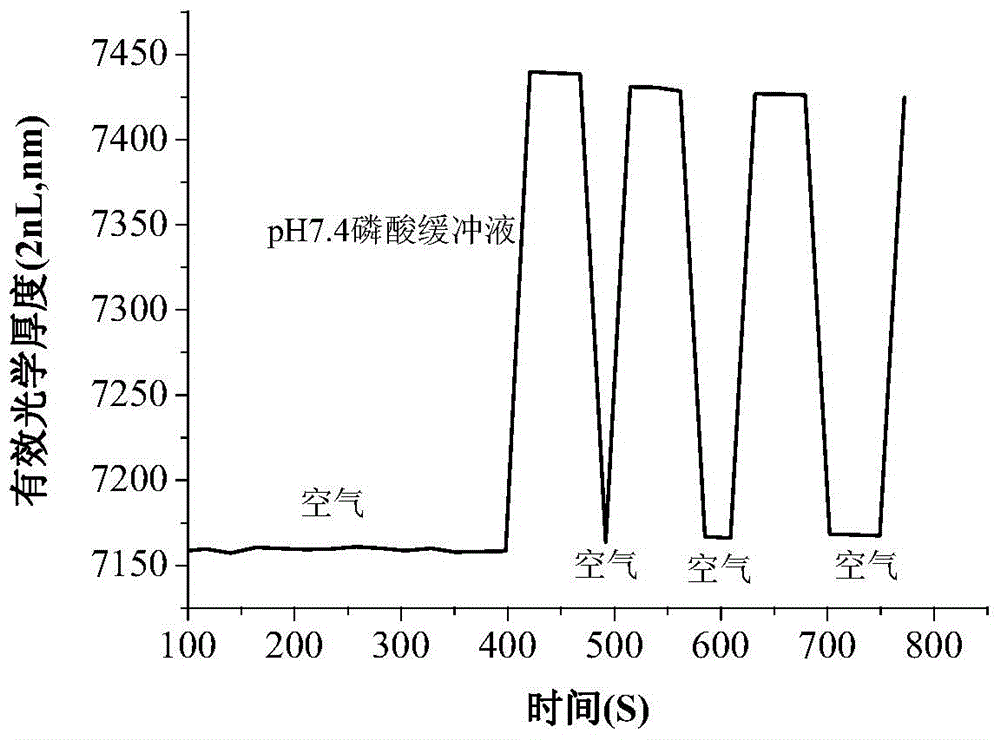

[0050] (5) Immobilization of liposomes and monosialoganglioside. Immobilization of liposome-monosialoganglioside on porous silicon surfaces via hydrophobic interactions. Specifically, the flow cell is first washed with deionized water for 15-20 minutes, then washed with pH7.4 phosphate buffer for 5 minutes, and then, 0.1mg / mL liposome and monosialoganglioside mixture through the flow cell until the optical thickness of the film reaches a stable value, see Figure 4 .

[0051] (6) Non-labeled on-line detection of cholera toxin: After washing the sample (containing cholera toxin solution) for 5 minutes with pH 7.4 phosphate buffer solution, the phosphate solution of 1nM cholera toxin...

Embodiment 3

[0053] Embodiment 3: Specific detection

[0054] Specificity detection 1: basically the same as Example 2, the difference is that the liposome microspheres without monosialoganglioside are immobilized on the hydrophobically modified silicon wafer (porous silicon film), and then according to the (6) For detection, the sample contains 20nM cholera toxin, see Image 6 . Depend on Image 6 It can be seen that after the introduction of 20nM cholera toxin, the optical thickness of the film does not red shift. This is because there is no receptor for cholera toxin on the surface of the film, and the cholera toxin is not bound to the surface of the film to cause a change in the refractive index of the film.

[0055] Specificity detection 2: basically the same as Example 2, the difference is that the sample is a phosphate buffer solution containing 20nM bovine serum albumin (without cholera toxin) circulating in the flow cell through a microflow pump, and monitoring the thin film opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com