Method and device for detecting quality of cigarette filter stick end face shape

A cigarette filter rod and filter rod technology, which is applied in the field of optical-mechanical-electrical integration devices, can solve problems such as difficult online high-speed detection, high labor intensity of workers, difficult filter rod cavity pattern detection, etc., and achieves the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Below in conjunction with accompanying drawing, the present invention is described in detail as follows:

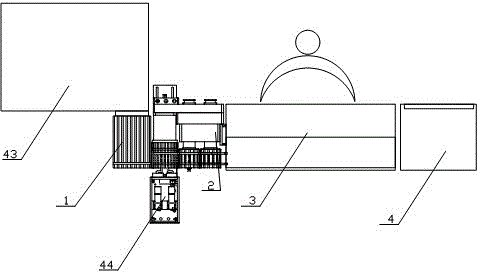

[0073] exist figure 1 , Figure 5-1 and 5-2 Among them, the device of the present invention includes a mechanism mounting plate 11, which is next to the filter rod end production equipment 43, and the mechanism mounting plate 11 is sequentially installed with a paging wheel 1, a photographing position drum 6, a rejecting position drum 7, and a receiving position. Material drum 8, material receiving table 3 and electric cabinet 4 are the six major parts, the visual module unit 44 is connected with the camera position drum 6, and the reject position drum 7 is equipped with a filter rod transmission and rejecting device 2, and the paging wheel 1 is responsible for Receive the filter rod from the filter rod end production equipment 43 and realize the regularization of the filter rod; the visual module unit 44 is responsible for visual image acquisition and analysis; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length and width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com