Detection core rod

A technology for detecting the core and mandrel body, applied in the field of auxiliary tools for detection, can solve problems such as poor contact surface, reduced product quality and service life, uneven loading, etc., and achieves the effect of convenient clamping and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

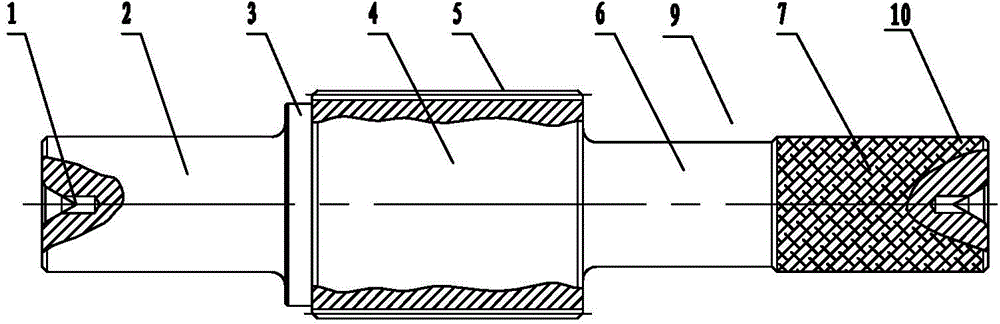

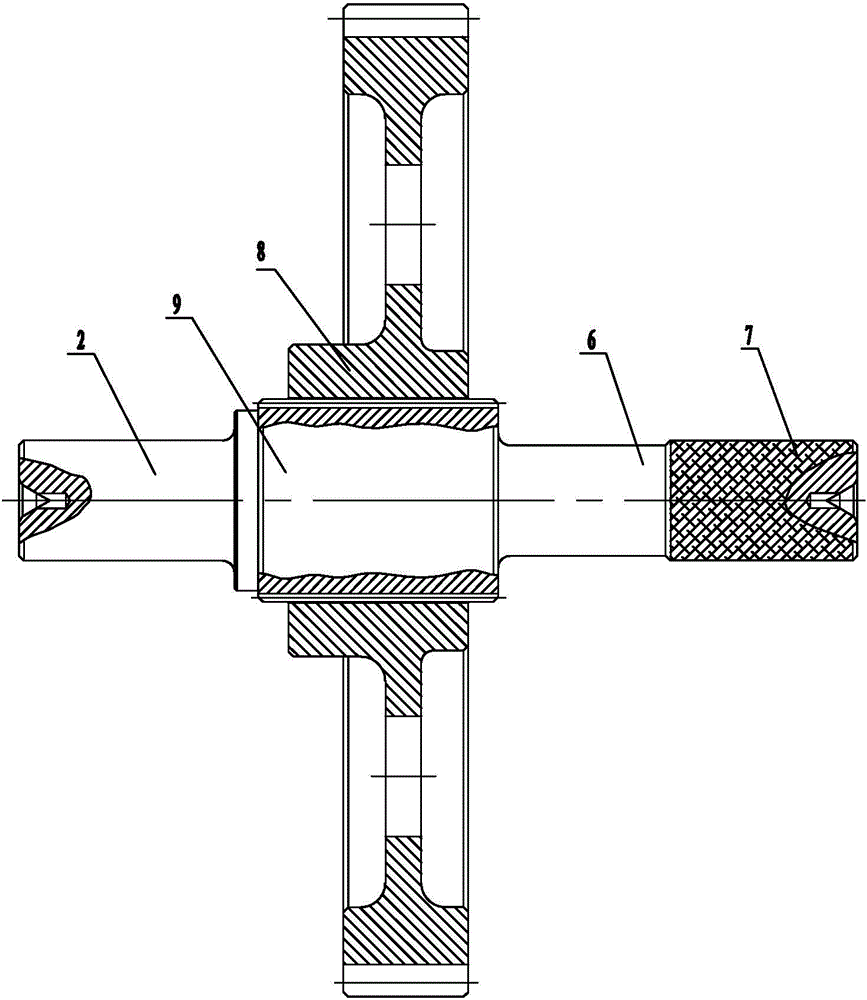

[0012] figure 1 , figure 2 It includes a central hole 1, a first cylinder 2, a second cylinder 3, a third cylinder 4, an involute external spline 5, a fourth cylinder 6, a fifth cylinder 7, and a workpiece to be inspected 8, Mandrel body 9, anti-slip pattern 10, etc.

[0013] Such as figure 1 , figure 2 As shown, the present invention is a detection mandrel, including a mandrel body 9, a central hole 1 is opened at the center of rotation at both ends of the mandrel body 9, and the surface of the mandrel body 9 is sequentially provided with first The cylinder 2, the second cylinder 3, the third cylinder 4, the fourth cylinder 6, and the fifth cylinder 7. The outer surface of the third cylinder 4 is processed with involute external splines 5.

[0014] The conditions between the first cylinder 2, the second cylinder 3, the third cylinder 4, the fourth cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com