Oil production well productivity tracking and evaluating method

An evaluation method and technology for oil production wells, applied in chemical instruments and methods, production fluids, earthwork drilling and production, etc., can solve problems such as poor effect, low efficiency, high risk, etc., and achieve good compatibility, high monitoring sensitivity, and easy identification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with specific embodiment:

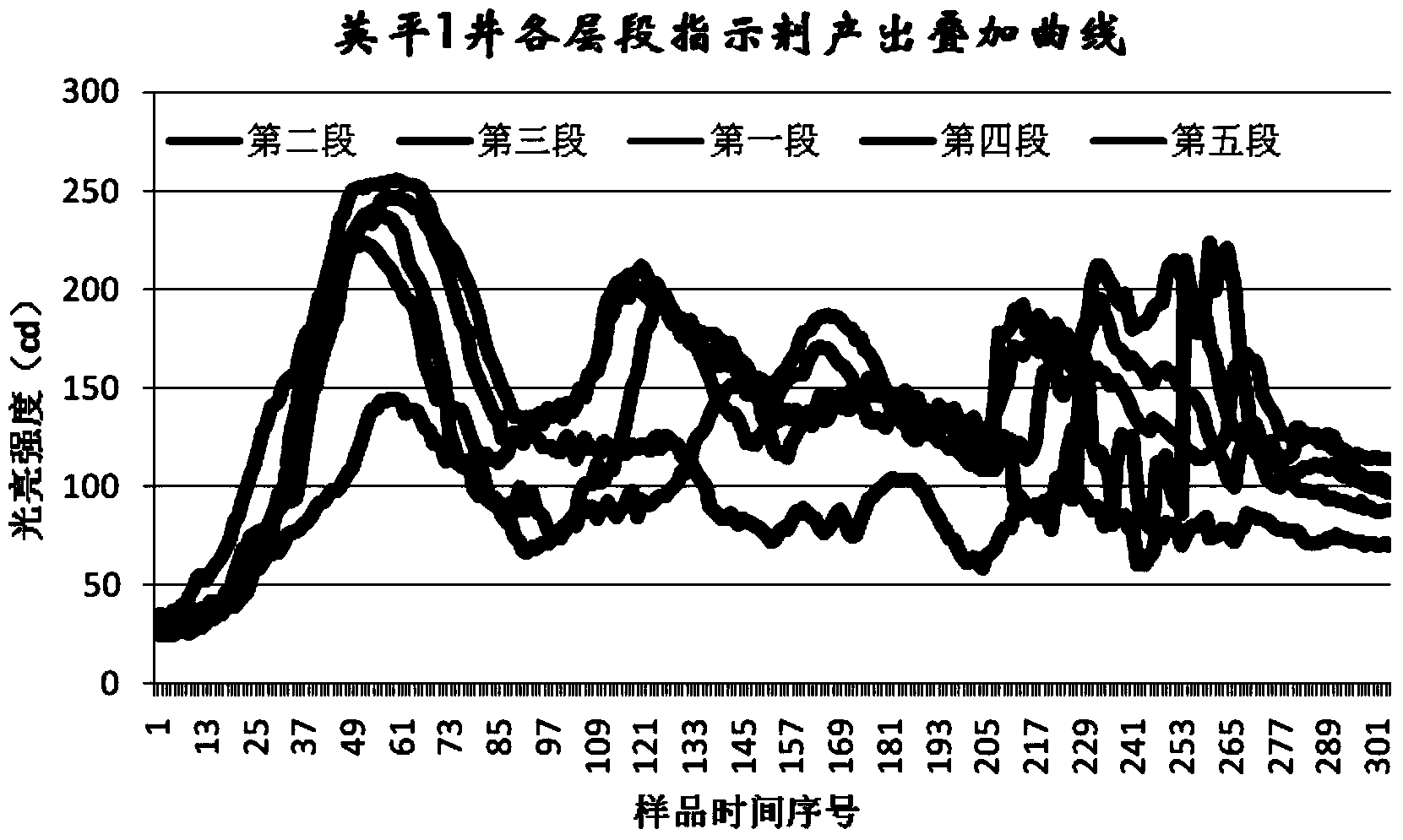

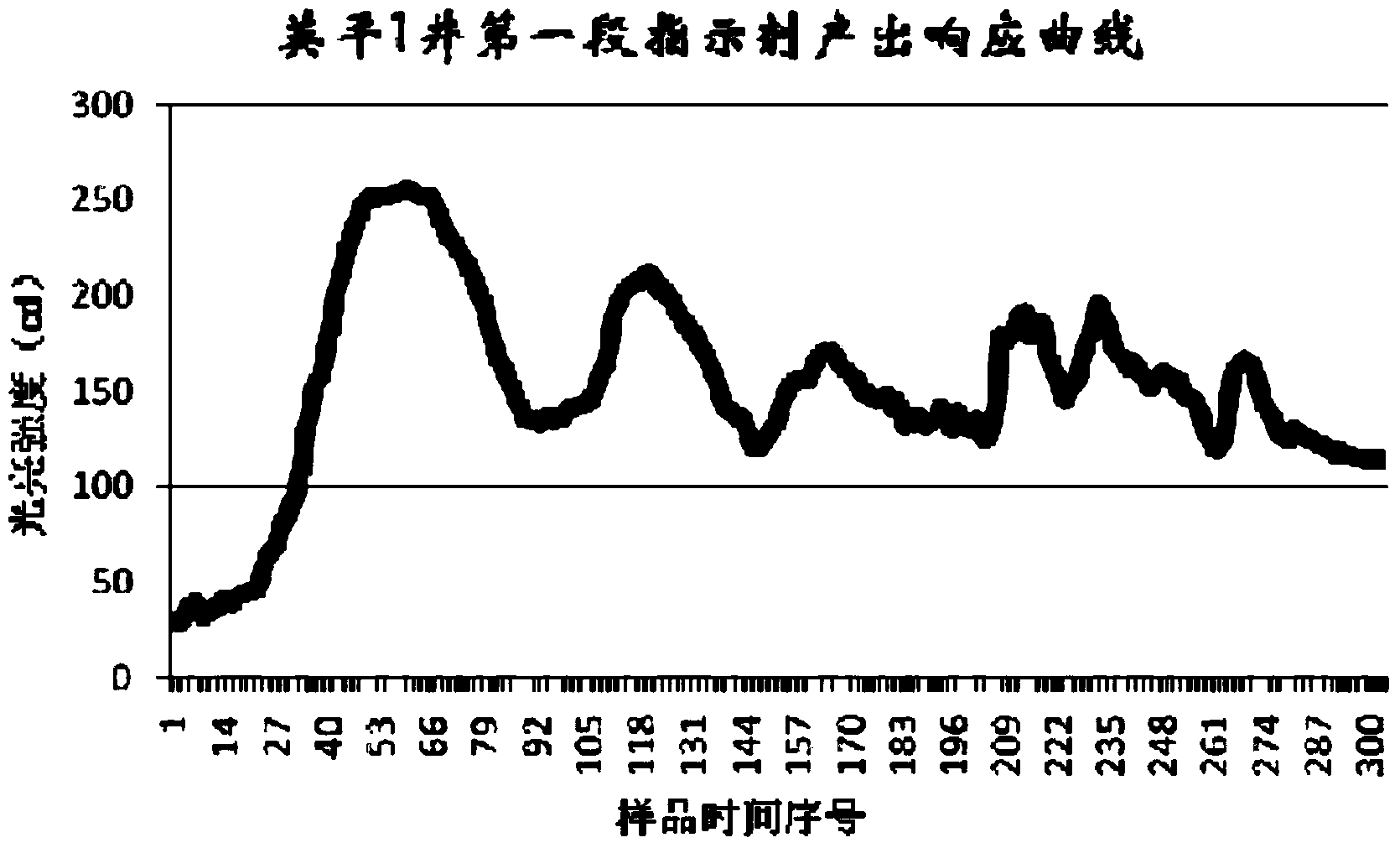

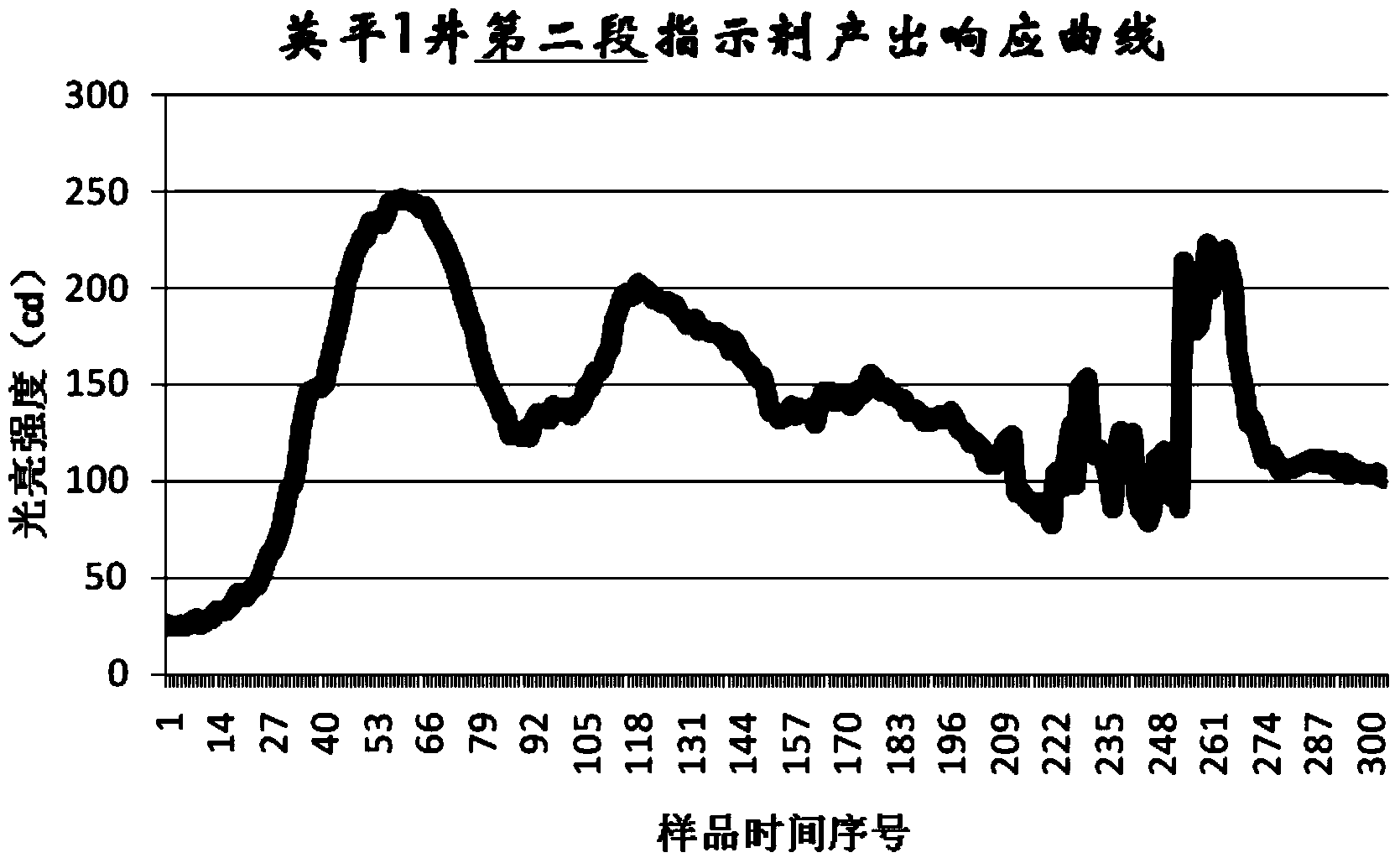

[0047] 1) During the fracturing process of the oil production well, add the indicator on the sand mixing vehicle when filling the pre-fluid and the sand-carrying fluid, and add the indicator according to the dosage table of the corresponding interval (see Table 1). In the fracturing sequence, five types of indicators, YTJ-3, YTJ-1, YTJ-2, YTJ-4 and YTJ-5, were added to the fracturing fluid of the first to fifth layers (stages), each 227L , 227L, 205L, 227L and 227L solutions, the whole liquid indicator addition process is uniform and stable (see Table 2).

[0048] Table 1 Amount of indicator dosing for staged fracturing in Well Yingping 1

[0049]

[0050] Table 2 Dosing liquid indicator on-site construction record form

[0051]

[0052]

[0053] 2) Tracking and monitoring of liquid indicators:

[0054] (1) Sampling method: during the flowback period of fracturin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com