Modified function material, blue photoresist material and color filter as well as preparation methods thereof and display device

A technology of color filter and blue photoresist, which is applied in the direction of optical filter, optical mechanical equipment, nonlinear optics, etc., can solve the problem of air quality decline, achieve the effect of improving air quality and improving human immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

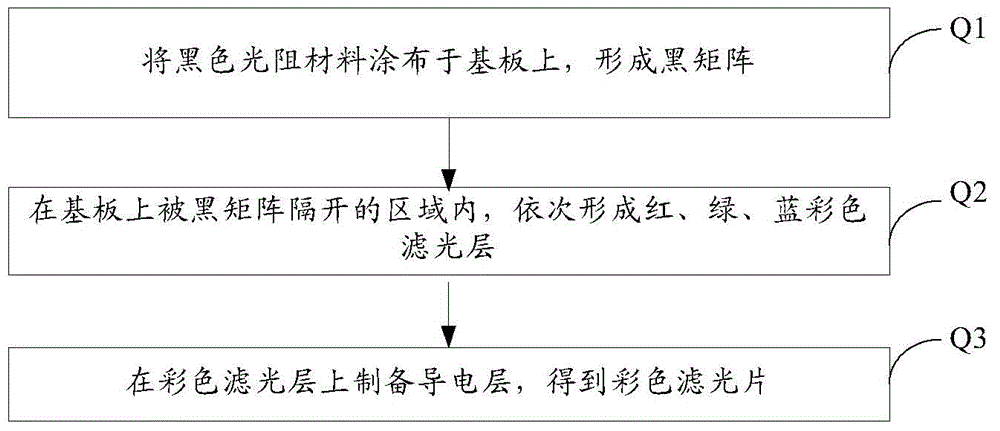

Method used

Image

Examples

Embodiment 1

[0129] Preparation of Modified Functional Material 1

[0130] First, weigh B by weight 2 o 3 2.875 parts, Na 2 O1.375 parts, Li 2 O5.05 parts, ZrO 2 15 parts, Al 2 o 3 11.25 parts and TiO 2 2.125 parts, put into a grinder and add a small amount of Solsperse3250 for dispersion and grinding to obtain the inorganic mixed dispersion of the above-mentioned components. Next, at 22°C, put the inorganic mixed dispersion into a four-necked bottle for constant stirring, then add 37.675 parts of propylene glycol monomethyl ether acetate, 37.675 parts of maleic anhydride and 28.256 parts of styrene into the four-necked bottle portion, and stir to combine. Again, nitrogen gas was introduced into the four-necked bottle. Then, 9.419 parts of azobisisovaleronitrile and 9.419 parts of styrene were mixed, and the mixed solution was added dropwise into a four-necked bottle to perform a reaction. Finally, after the reaction was completed, the reaction solution in the four-neck bottle ...

Embodiment 2

[0132] Preparation of modified functional material 2

[0133] First, weigh B by weight 2 o 3 3.83 parts, Na 2 O1.83 parts, Li 2 O6.73 parts, ZrO 2 20 copies, Al 2 o 3 15 parts and TiO 2 2.83 parts, put into a grinder and add a small amount of Solsperse 3250 for dispersion and grinding to obtain the inorganic mixed dispersion of the above components. Next, at 24°C, put the inorganic mixed dispersion into a four-necked bottle for constant stirring, then add 50.22 parts of propylene glycol monomethyl ether acetate, 50.22 parts of maleic anhydride and 37.665 parts of styrene to the four-necked bottle portion, and stir to combine. Again, nitrogen gas was introduced into the four-necked bottle. Then, 12.555 parts of azobisisovaleronitrile and 12.555 parts of styrene were mixed, and the mixed solution was added dropwise into a four-necked bottle to perform a reaction. Finally, after the reaction was completed, the reaction solution in the four-neck bottle was cooled at 4° C...

Embodiment 3

[0135] Preparation of modified functional material 3

[0136] First, weigh B by weight 2 o 3 5.75 parts, Na 2 O2.75 parts, Li 2 O10.1 parts, ZrO 2 30 parts, Al 2 o 3 22.5 parts and TiO 2 4.25 parts, put into a grinder and add a small amount of Solsperse3250 for dispersion and grinding to obtain the inorganic mixed dispersion of the above components. Next, at 26°C, put the inorganic mixed dispersion into a four-necked bottle for continuous stirring, then add 75.35 parts of propylene glycol monomethyl ether acetate, 75.35 parts of maleic anhydride and 56.512 parts of styrene to the four-necked bottle portion, and stir to combine. Again, nitrogen gas was introduced into the four-necked bottle. Then, 18.838 parts of azobisisovaleronitrile and 18.838 parts of styrene were mixed, and the mixed solution was added dropwise into a four-necked bottle to perform a reaction. Finally, after the reaction was completed, the reaction solution in the four-neck bottle was cooled at 6°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com