Universal movement mechanism of 3D printer

A technology of 3D printers and motion mechanisms, applied in printing, transfer materials, power transmission devices, etc., can solve problems such as insufficient level, tilt of the workbench, and influence on the precision of printed objects, so as to improve printing speed and solve problems Effects of resonance and noise problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, technical features, purpose and technical effects of the present invention easy to understand, the present invention will be further explained in conjunction with specific drawings below.

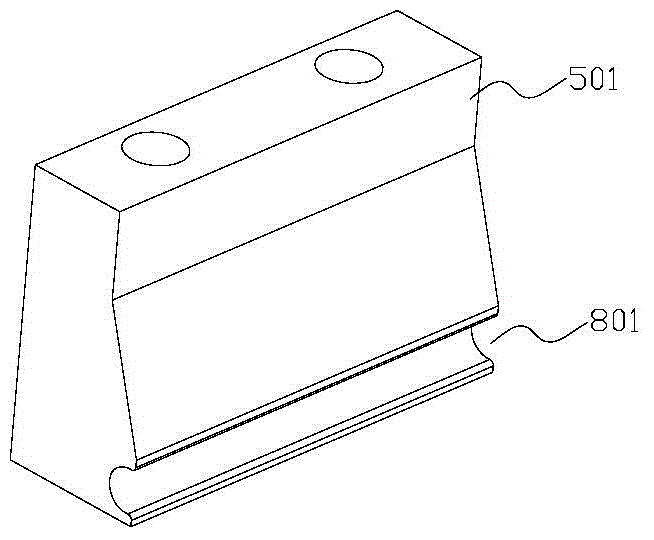

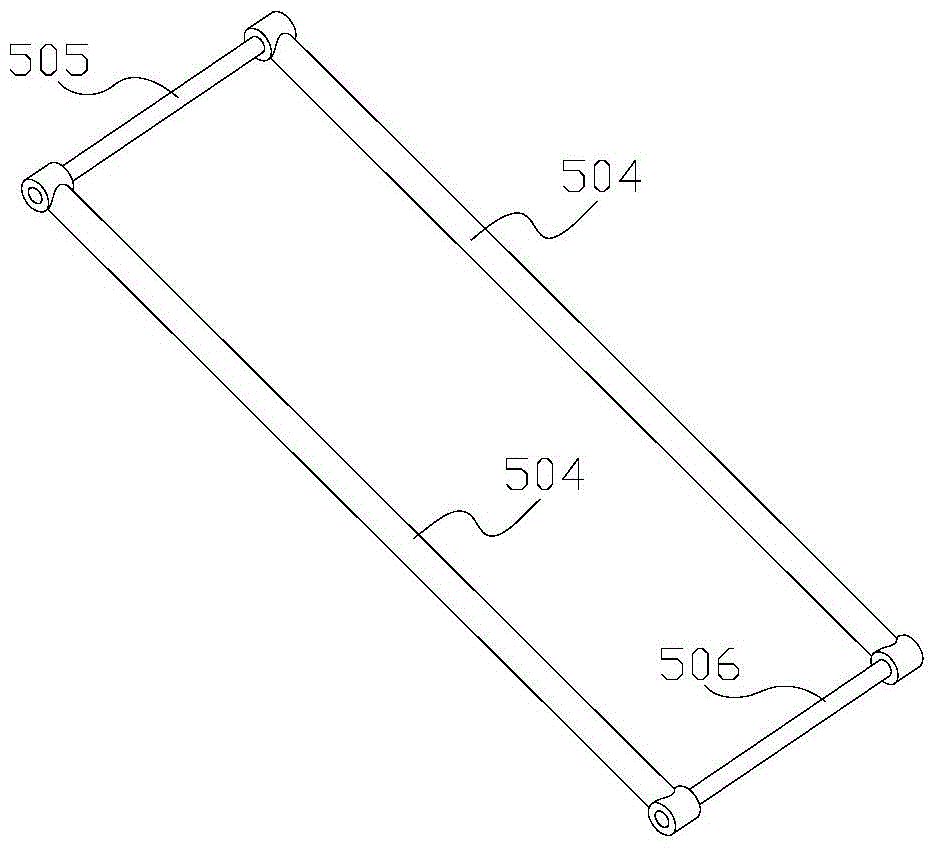

[0020] Such as figure 1 Shown here is a universal movement mechanism for a 3D printer of the present invention, including a mechanism top 100, a mechanism bottom 200, a material extruding device 300, and a workbench 400. The mechanism top 10 and the mechanism top 200 of the present invention are both compatible with the 3D printer The body is connected to fix the movement mechanism on the 3D printer.

[0021] The workbench 400 in the present invention is installed between the top 100 of the mechanism and the bottom 200 of the mechanism, and the height of the workbench 400 from the top 100 of the mechanism is greater than the height of the bottom 200 of the mechanism. The material extruding device 300 of the present invention is located above the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com