Full-digital high-power plasma arc precise cutting system

A plasma arc and cutting system technology, applied in the field of ion arc fine cutting system, can solve the problems of insufficient control of cutting process, large influence of plasma cutting system, limited process parameters and status information, etc., and achieve friendly human-computer interaction , Product consistency is good, and the status display is intuitive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

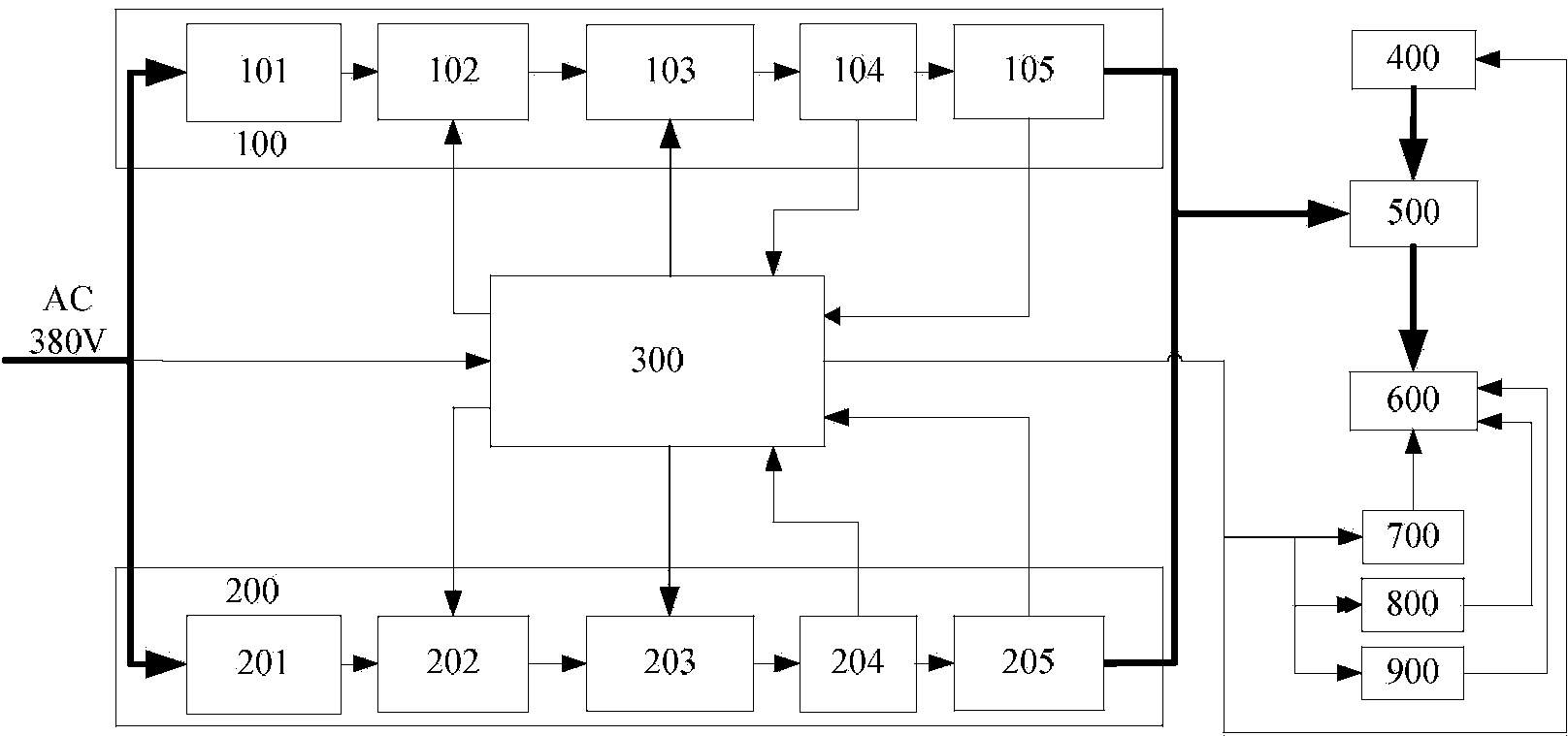

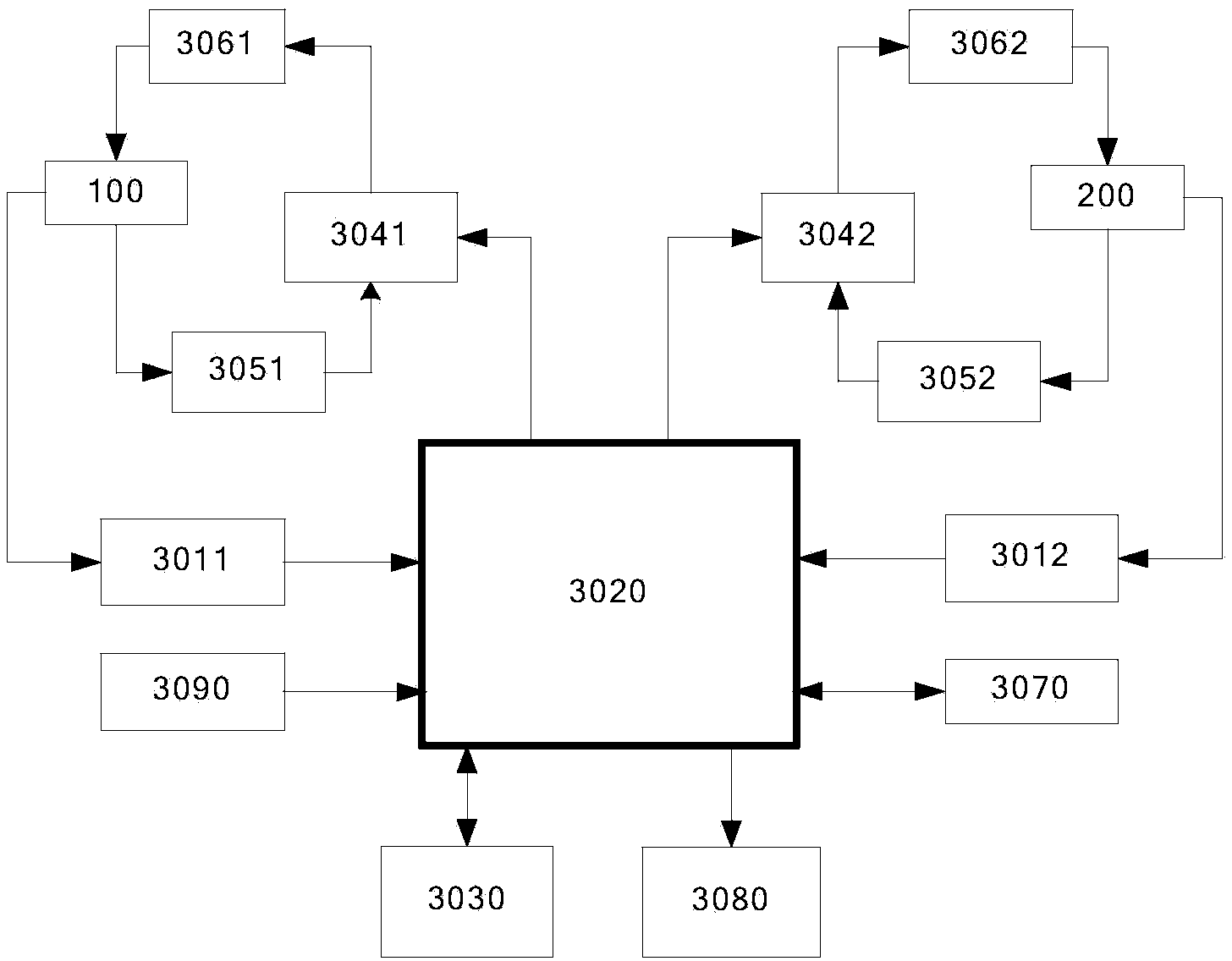

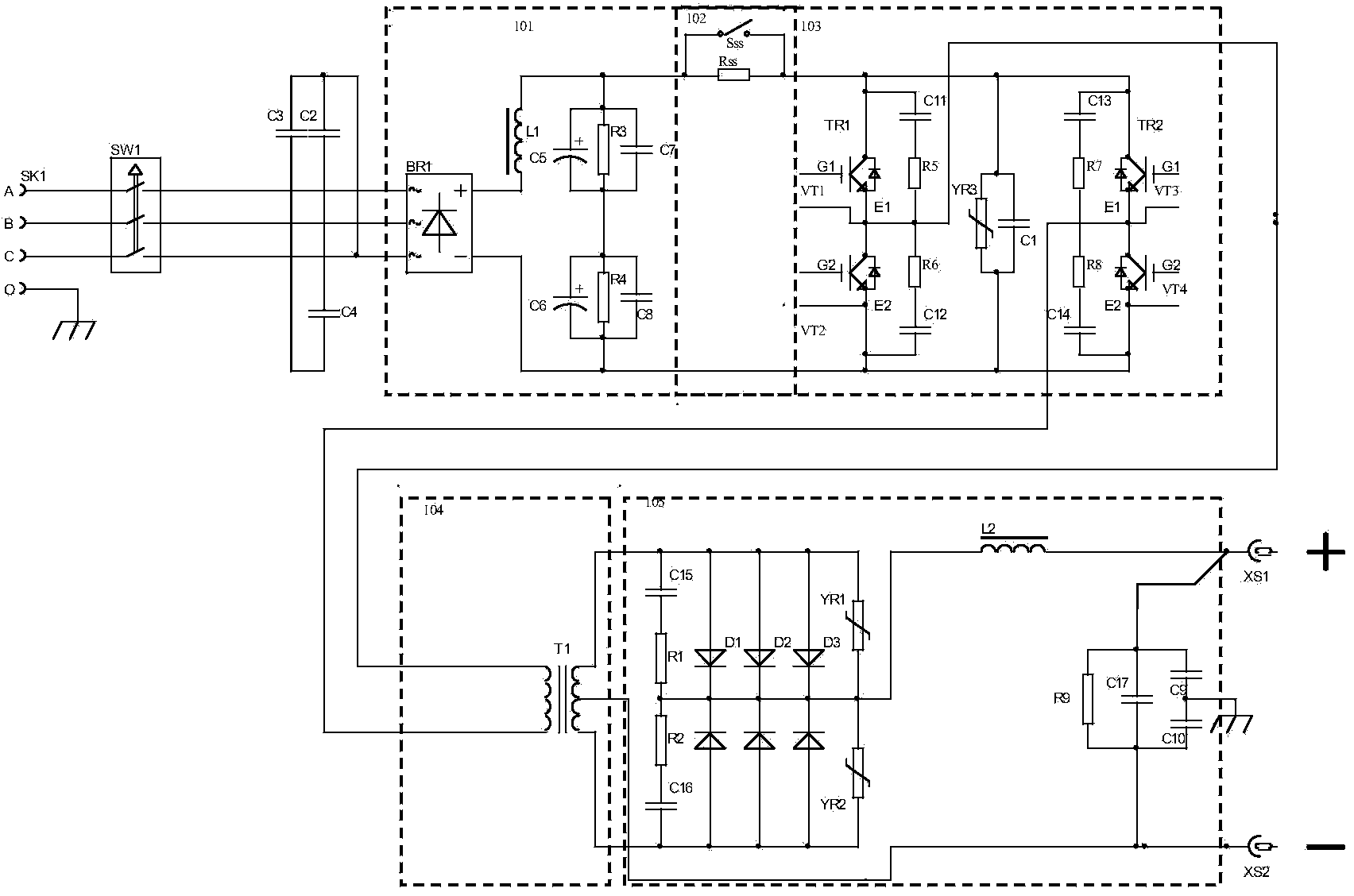

[0027] The all-digital high-power plasma arc fine cutting system described in the present invention, such as figure 1 As shown, it mainly includes a power circuit formed by parallel connection of power module one 100 and power module two 200, a control circuit 300, a high-frequency arc ignition module 400, a coupled reactance module 500, a plasma arc cutting torch 600, a cooling system 700, and compressed air System 800 and cutting carriage 900 . The first power module 100 and the second power module 200 have the same structure, respectively composed of rectification and filtering modules 101 and 201, soft start modules 102 and 202, high frequency inverter modules 103 and 203, power transformer modules 104 and 204, and rectification smoothing module 105 and 205 are connected in sequence. Wherein, the rectification and filtering modules 101 and 201 are externally connected to a three-phase AC input power supply, and the rectification and smoothing modules 105 and 205 are exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com