Skimmer

A skimmer and box technology, which is applied in the field of devices for removing and mixing suspended matter to be removed, can solve the problems of incomplete separation of suspended matter and fluid medium, unfavorable continuous production, large pool area, etc., and achieve structural The effect of simplicity, low manufacturing cost, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

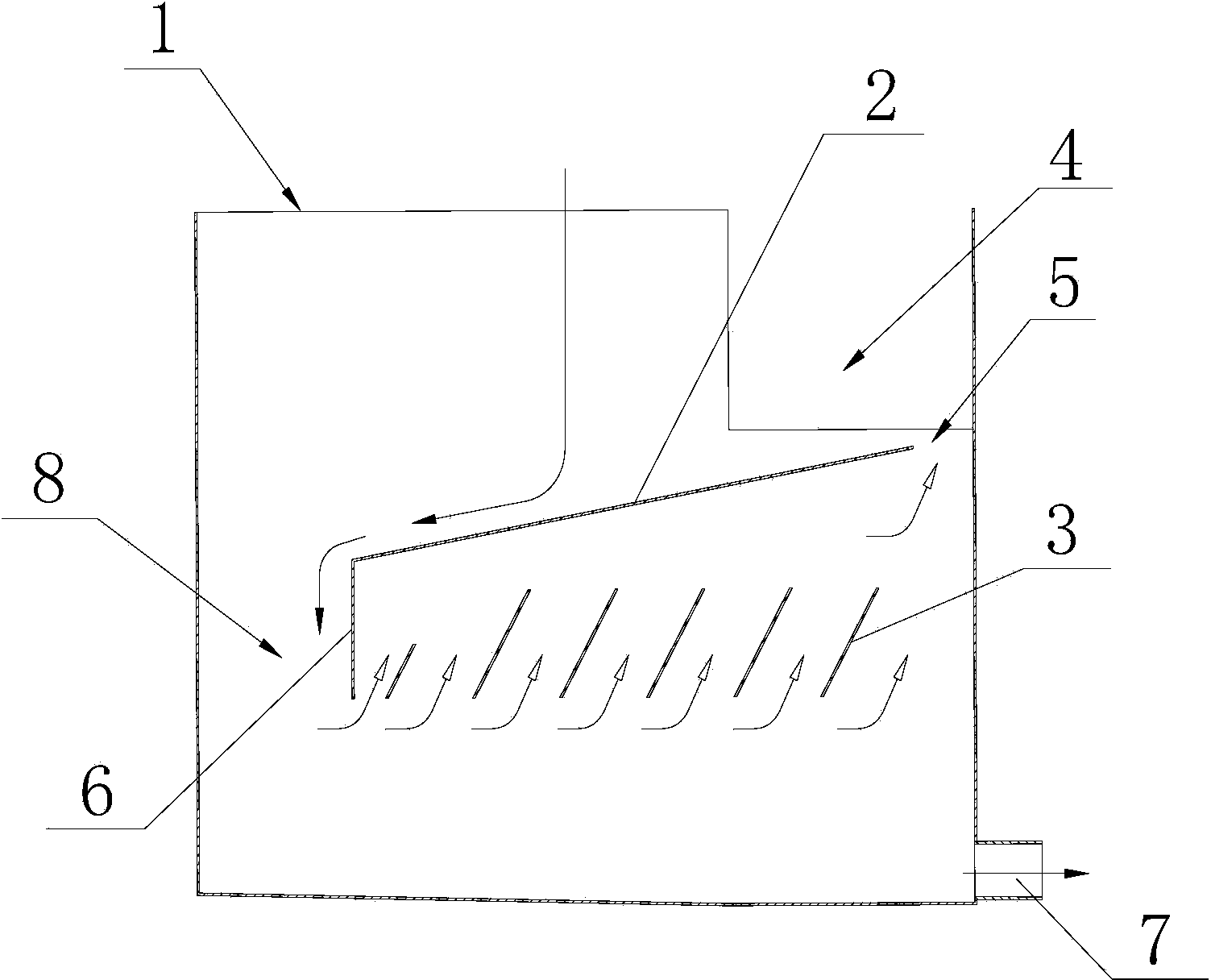

[0025] see figure 1 , The skimmer of the present invention includes a box body 1 provided with a mixed fluid inlet at the upper end. The box body 1 is in the shape of a cuboid and is formed by connecting a front plate, a rear plate, a left plate, a right plate and a bottom plate. The upper part of the box body 1 is provided with a suspension outlet 4, and the lower part is provided with a fluid medium outlet 7. Described box body 1 is provided with deflector baffle 2, and this deflector baffle 2 is arranged inclined up and down, and the front edge and rear edge of this deflector baffle 2 are respectively connected with the inner wall of the front plate of box body 1 and the back plate. The inner walls are connected, thereby dividing the interior of the box body 1 into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com