Production method of porcine circovirus type 2

A technology of porcine circovirus and its production method, which is applied in the production process field of the spinner bottle culture method, can solve problems such as difficult to meet the requirements of vaccine matching, low antigen titer of semi-finished products, hidden dangers of vaccine quality, etc., achieve easy quality, improve vaccine quality and output , The production process is simple and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

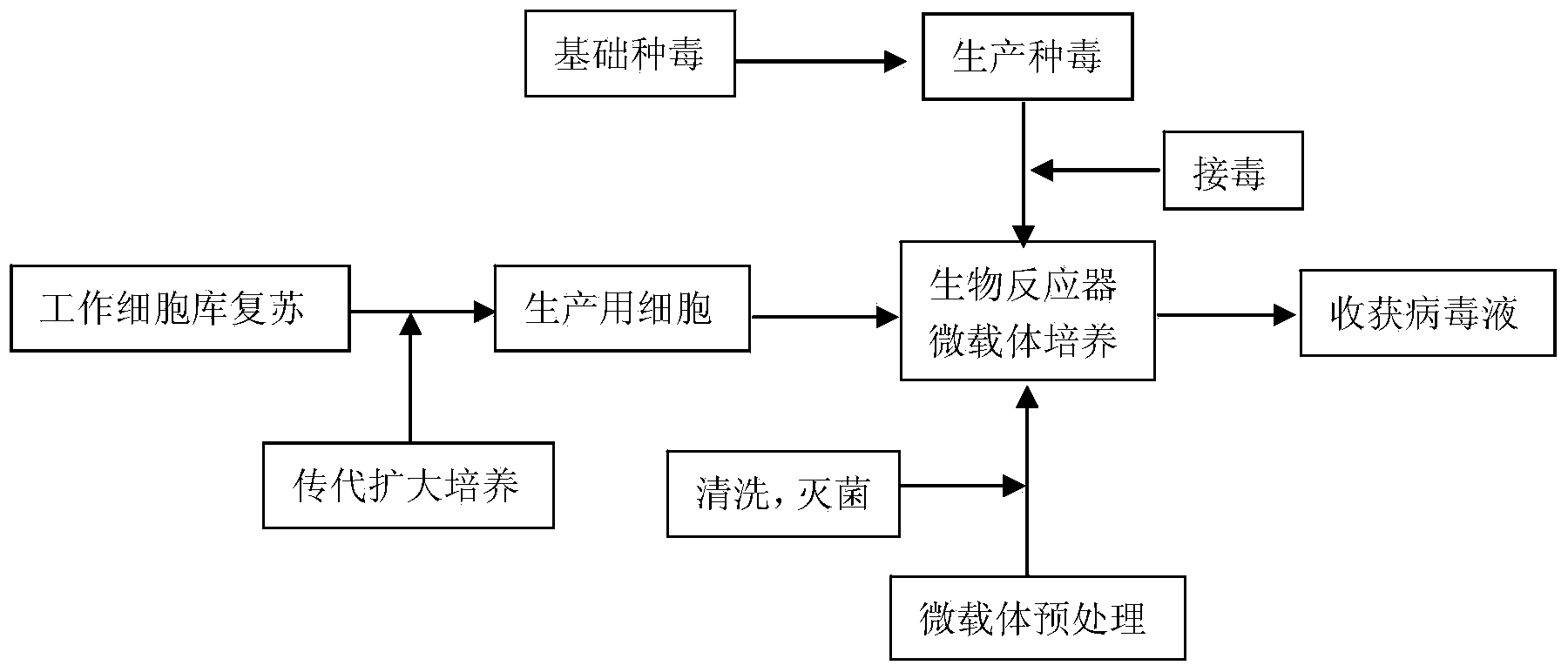

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0039] (1) Choose a bioreactor as a means of cultivation: 3L-3000L bioreactor.

[0040] (2) Select microcarriers as the carrier for cell-attached growth

[0041] Microcarrier cleaning and sterilization methods:

[0042] 1) Weigh 3-5g / L of Cytodex microcarriers and soak them in an appropriate amount of PBS for three hours.

[0043] 2) Wash 3 times with appropriate amount of PBS each time.

[0044] 3) Add an appropriate amount of PBS solution to soak the microcarriers, and steam sterilize at 121°C for 30 minutes.

[0045] (3) Select pK-15A1# cells as cells for seedling production:

[0046] (4) Subculture and cultivation of cells for seedling production:

[0047] The above cells were digested and passaged with trypsin digestion solution (containing 0.25% trypsin (1:250)), and then cultured with growth medium at a temperature of 37.0 (±0.2) °C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com