Method and device for non-contact measurement of surfaces

A non-contact measurement and measurand technology, applied in the direction of measurement device, geometric characteristic/aberration measurement, using optical device, etc., can solve problems such as discontinuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

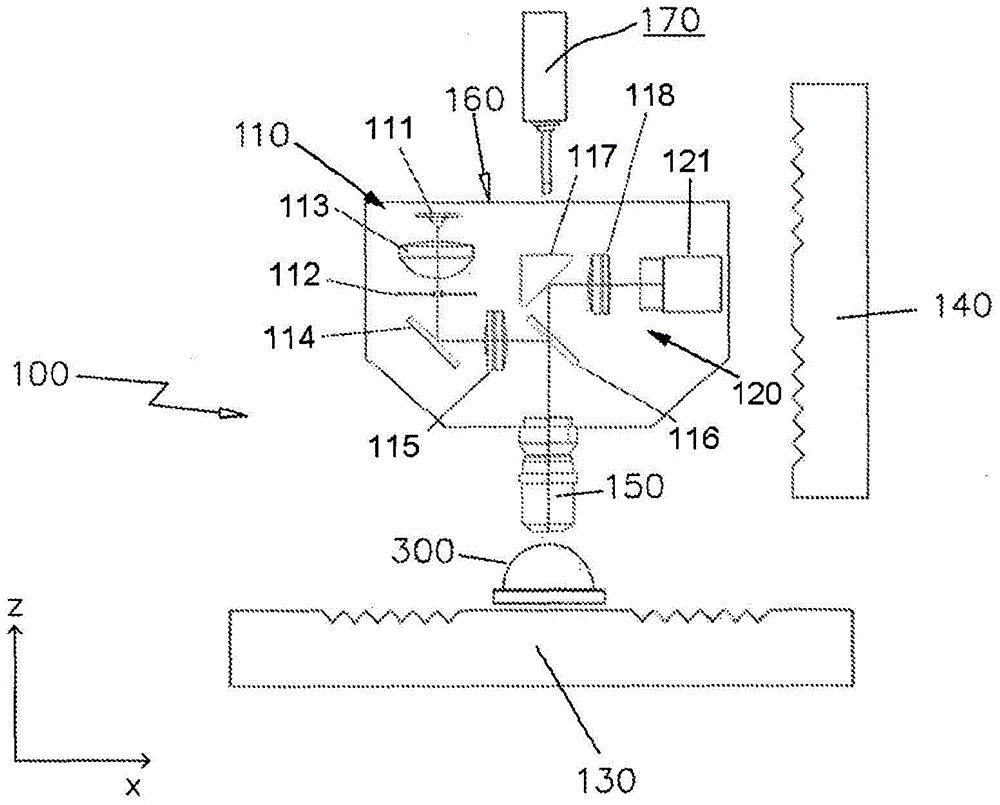

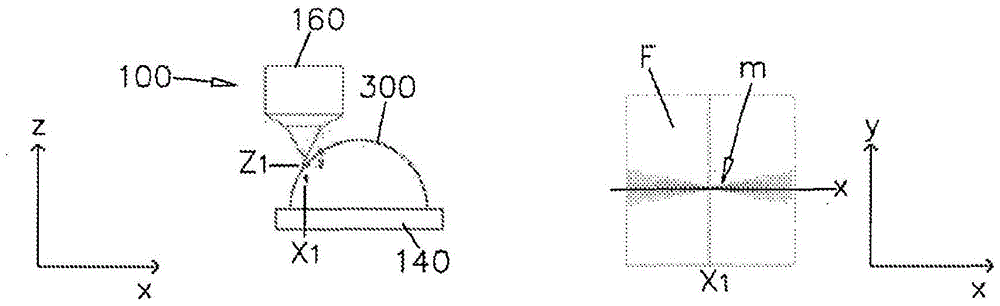

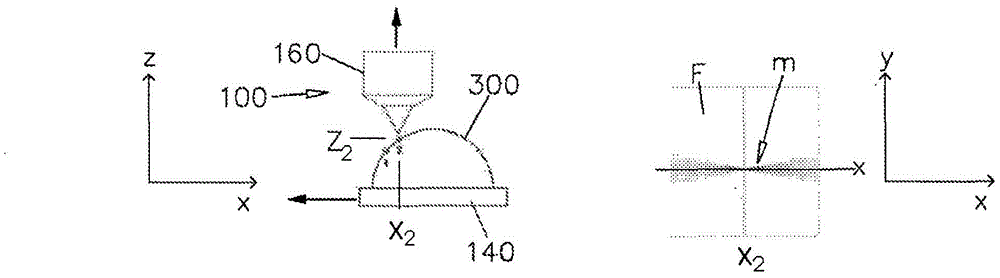

[0099] The drawings illustrate an exemplary embodiment of a non-contact, high-precision, rapid measurement device. figure 1 A non-limiting example of the device shown in is generally indicated by 100 . Optical profilers are capable of measuring any optical surface. While useful in many applications, the present example relates to a measurement device 100 for non-contact measurement of the surface of a lens. The lens is generally indicated at 300 in the drawings herein.

[0100]The measurement device 100 comprises a light projection arrangement 110 comprising one or a series of LEDs 111 . Such a light projection device 110 in the shown device 100 is suitable for projecting a pattern of structured light through an aperture 112 onto a target area of the lens 300 . Such as figure 1 As shown in , the light projection device 110 further includes a collimating optics 113 , a 45° mirror 114 , an optical lens 115 , a beam splitter 116 and a microscope objective 150 .

[0101] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com