Shedding equipment for looms

A shed and equipment technology, applied in the field of shed forming equipment, can solve the problems of increased energy consumption and achieve the effect of reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

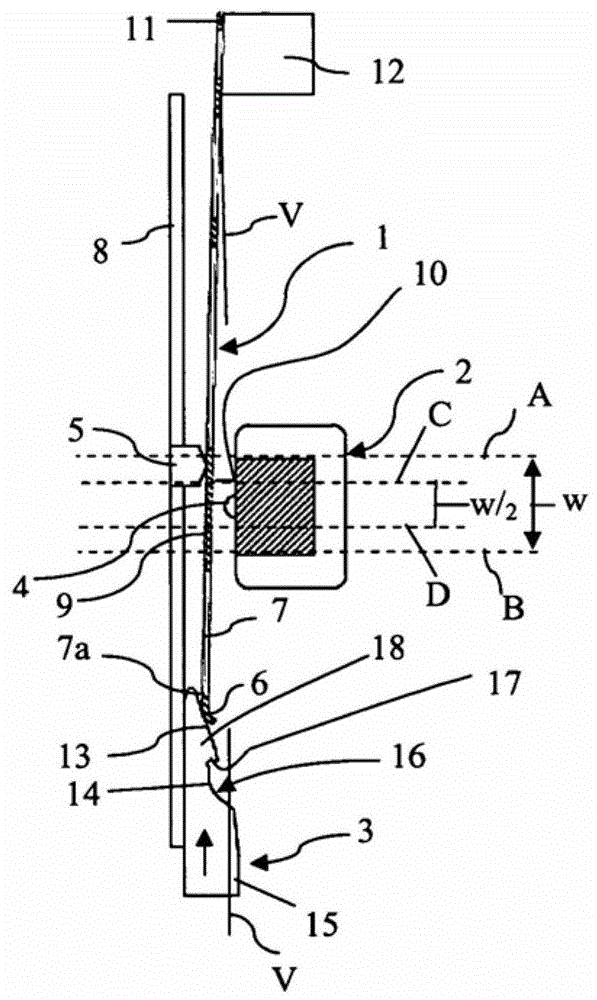

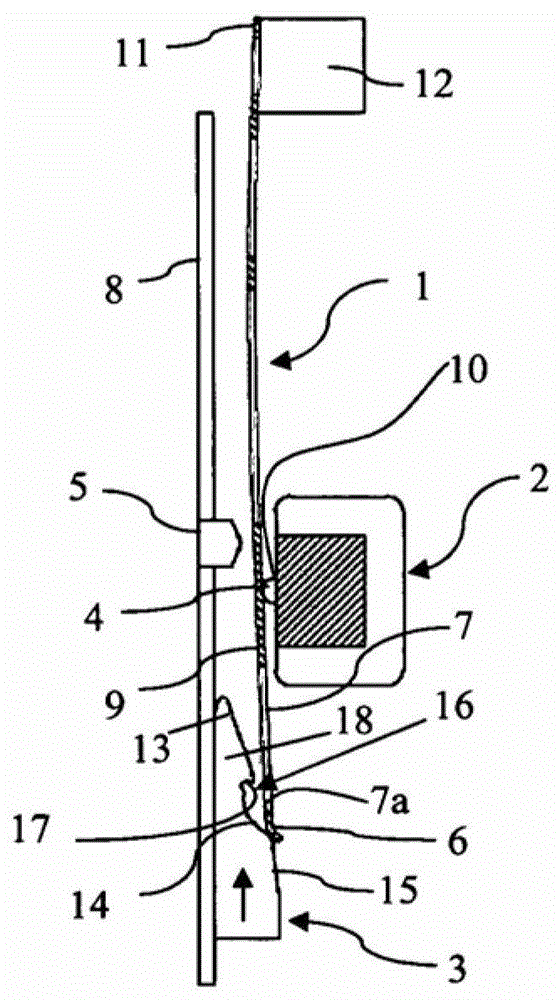

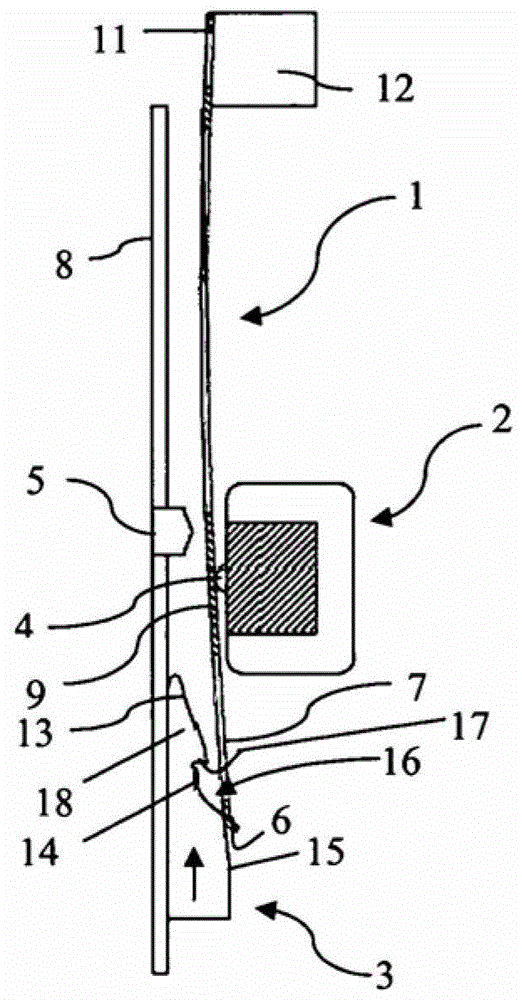

[0111] exist Figures 1 to 19 In the arrangement shown schematically, the selection element (1) is designed in each case as a thin strip of flexible and elastically deformable material, the upper end (11) of the selection element being attached to the shedding device fixed part (12). The attached selector element (1) extends at a small angle to the left in the vertical direction (V). There is a fixed support element (5) on the left hand side of the needle selection element. If no force is applied to the selector element (1), the selector element (1) rests against the fixed support element (5) due to its elasticity, as a result, it is subjected to a slight prestress which counteracts the Warp to the right. The support element (5) ensures the position of the needle selection element (1) relative to other components, in particular relative to the presentation device.

[0112] The needle selector element (1) has at its free end an end (6) bent to the right at an obtuse angle a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com