Vent valve structure

A technology of vent valve and vent channel, which is applied in the direction of valve shell structure, valve details, safety valve, etc., can solve problems such as oil leakage, achieve the effects of preventing oil leakage, simple production, and solving oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

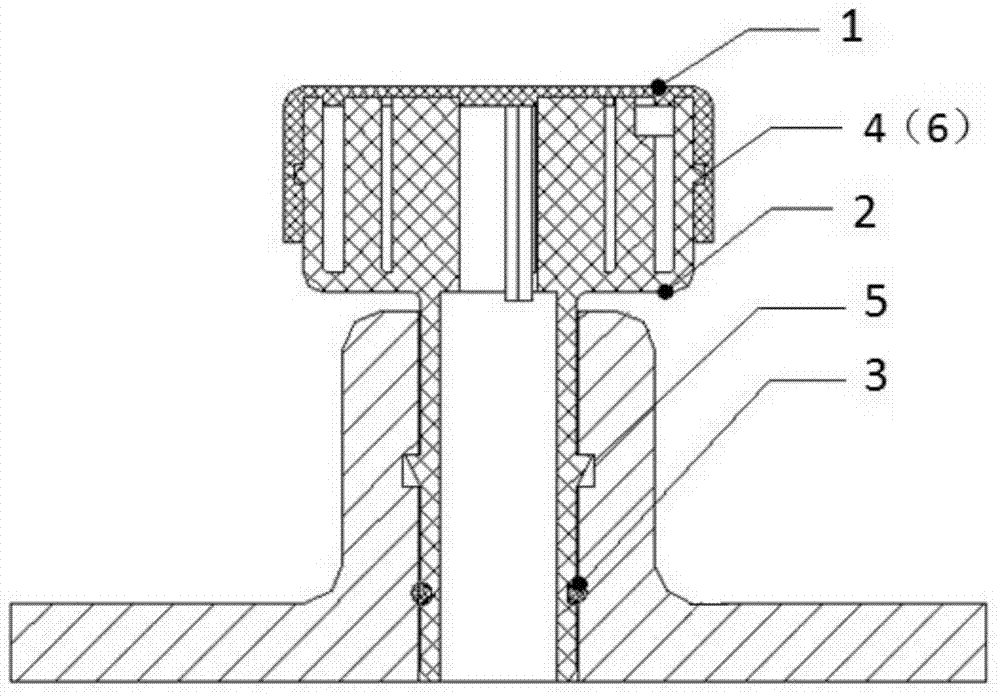

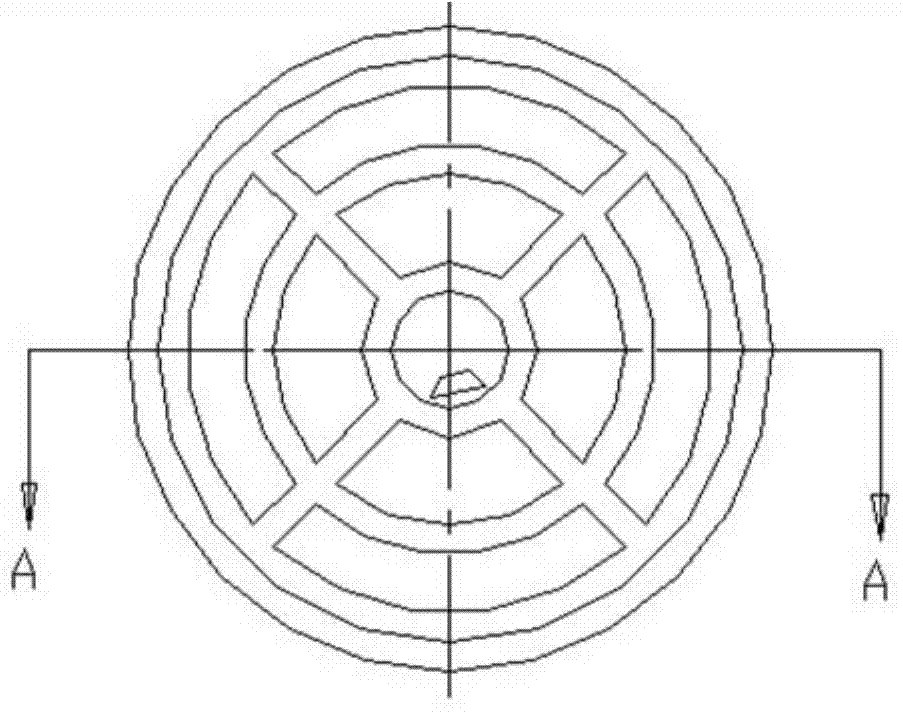

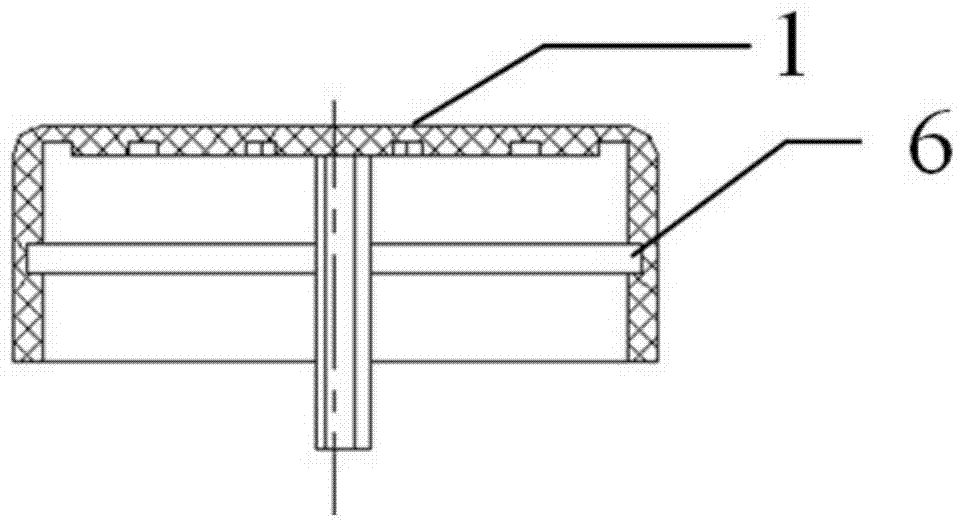

[0029] Such as figure 1 As shown, the embodiment of the present invention provides a ventilation valve structure, including: a valve cover 1, a valve body 2; an O-ring notch 3 is provided on the valve body 2; Body interference fit O-ring; valve body 2 is provided with a labyrinth ventilation channel capable of condensing oil vapor in gas.

[0030] It can be seen that in the embodiment of the present invention, an O-ring notch is provided on the valve body, and an O-ring with an interference fit with the box body is installed in the notch to ensure good sealing between the vent valve and the box body , Solved the problem of oil leakage of the vent valve. The oil in the evaporating gas can be condensed by setting the labyrinth ventilation channel, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com