Three-way frequency-adjustable dynamic vibration absorber

A technology of dynamic shock absorber and shock absorber, which is applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems that cannot meet the three-way vibration absorption, and achieve compact structure, suppression of line spectrum peak, and installation space The effect of little demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

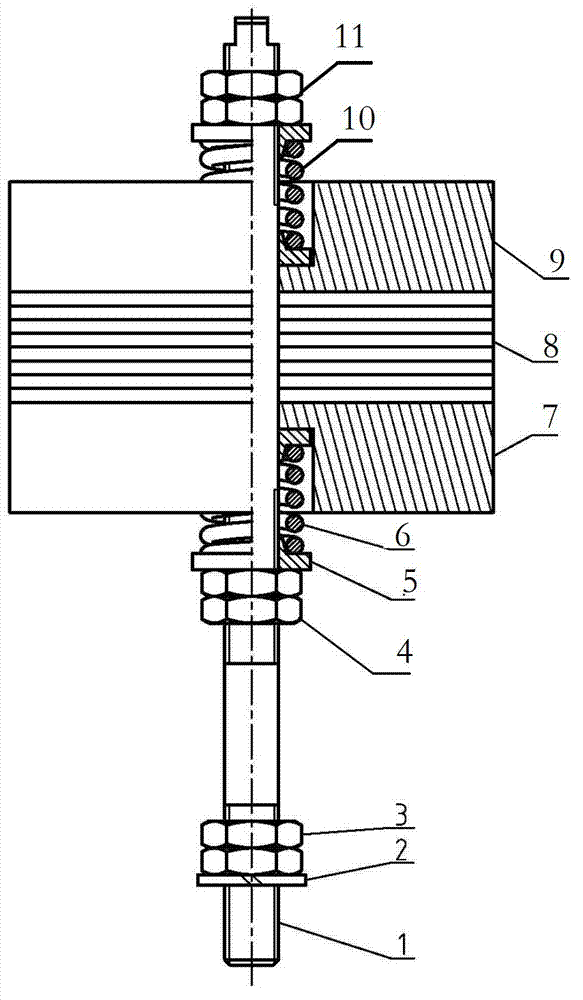

[0020] Example 1, such as figure 1 As shown, the three-way adjustable frequency dynamic vibration absorber of the present invention mainly includes a guide rod, a middle nut 4, an upper nut 11, a lower spring 6, an upper spring 10, a lower fixed mass 7, an upper fixed mass 9 and more than two FM mass block8.

[0021] The connection relationship between the above parts is as follows: the lower fixed mass 7, the frequency modulation mass 8 and the upper fixed mass 9 are sequentially set on the guide rod 1, the middle nut 4 cooperates with the lower spring 6 and the upper nut 11 cooperates with the upper spring 10 to fix the lower end Mass block 7, multiple frequency modulation mass blocks 8 and upper fixed mass block 9 are fixed on guide rod 1 by pre-tightening force.

[0022] The frequency modulation principle of the three-way adjustable frequency dynamic vibration absorber of the present invention is as follows:

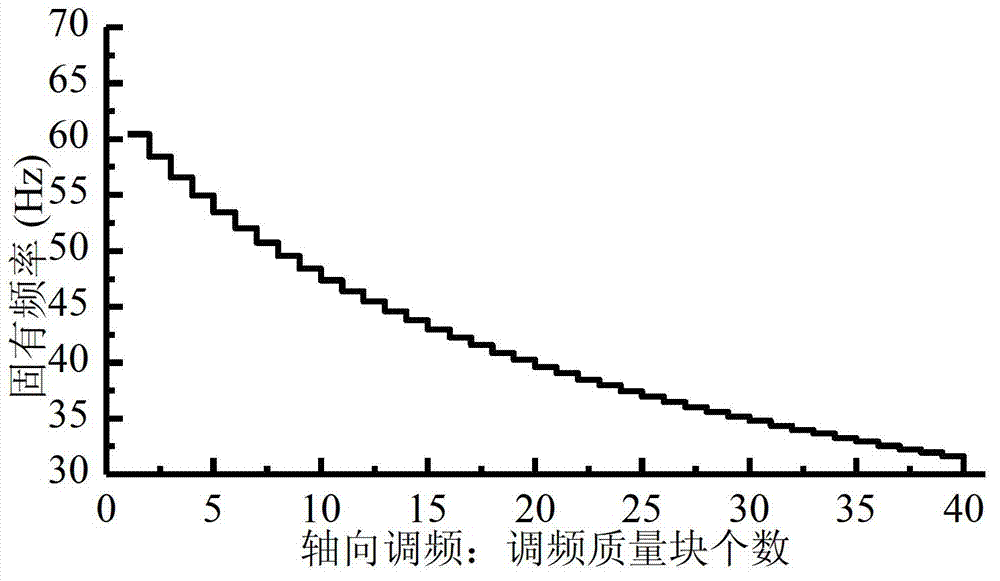

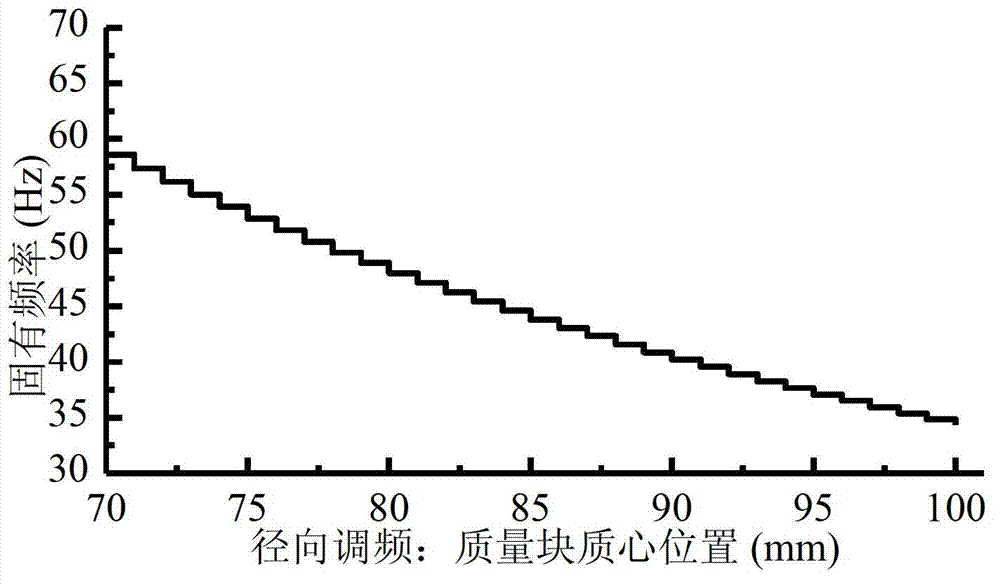

[0023] The principle of axial frequency modulation: according...

Embodiment 2

[0045] Embodiment 2, on the basis of embodiment 1, the surface of the non-threaded part on the guide rod 1 is plated with chrome to improve the surface hardness and smoothness, thereby reducing the friction between the mass block and the guide rod 1 and reducing the wear of the guide rod 1; All parts of the invention are made of corrosion-resistant stainless steel, which can withstand high and low temperature, oil pollution, radiation, and corrosion, thereby improving environmental adaptability.

Embodiment 3

[0046] Embodiment 3, on the basis of Embodiment 1 or 2, the nut locking method can be changed to a slotted nut with cotter pin, so that the height of the original nut can be reduced while realizing the anti-loosening function, so that the guide rod 1 is shortened, The installation space requirement of the invention is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com