Automatic test system of axial flow fans

A fully automatic test and axial flow fan technology, applied in the direction of machine/engine, mechanical equipment, pump control, etc., can solve the problems of easy error, poor reliability, time-consuming and labor-intensive, etc., to increase reliability, reduce participants, improve The effect of measuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

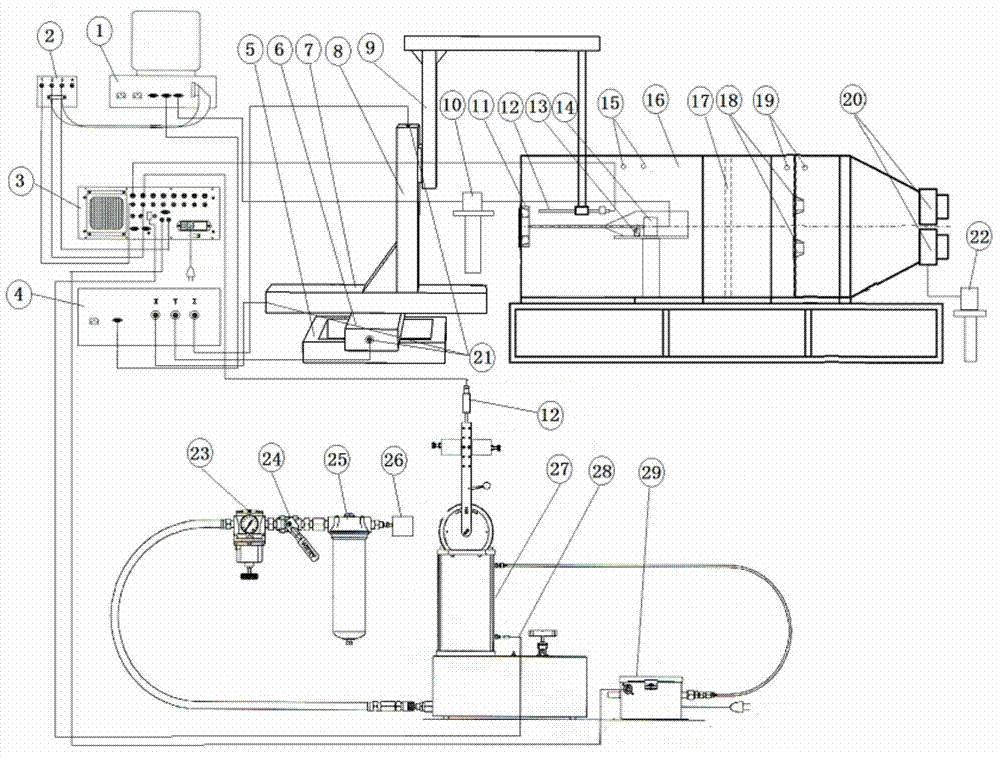

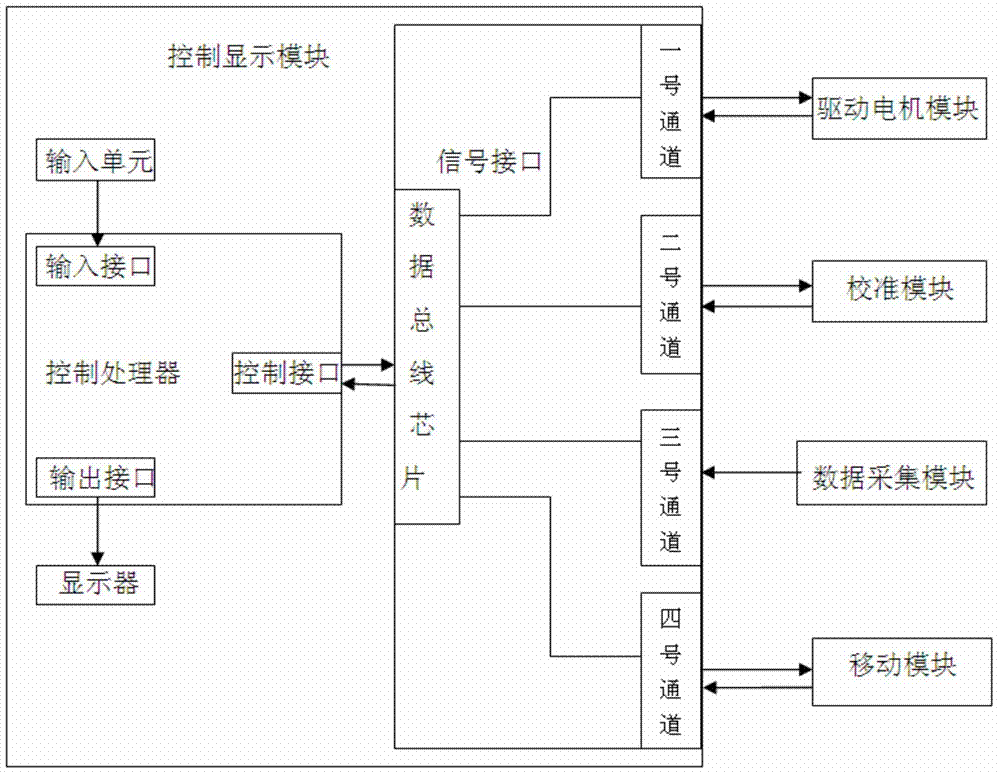

[0038] A fully automatic testing system for an axial flow fan, comprising a control display module, a drive motor module, a data acquisition module, a wind tunnel module, a calibration module and a moving module.

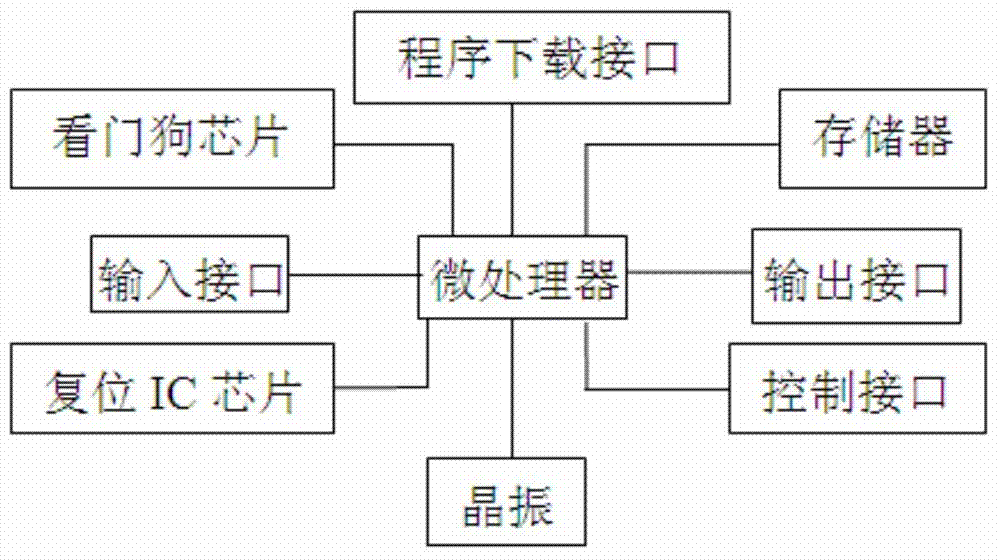

[0039] The control display module 1 includes a control processor, an input unit, a display and a data bus chip;

[0040] The drive motor module includes a programmable voltage stabilized power supply 10 and a drive motor 14;

[0041] The data acquisition module includes a hot wire probe 12, an axial flow fan velocimeter 3, a data acquisition card 2 and a pressure sensor 29;

[0042] The mobile module includes a mobile controller 4 and a mobile coordinate frame, and the mobile coordinate frame includes a base 5, a Y-axis slider 6, an X-axis slider 7, a Z-axis slider 8, a U-shaped bracket 9 and a stepper motor 21 ;

[0043]The calibration module includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com