A kind of silk fabric natural essential oil fragrance finishing agent and preparation method thereof

A technology of aromatic finishing agent and natural essential oil, applied in microsphere preparation, fiber processing, animal fiber and other directions, can solve problems such as uncomfortable odor, overcome limitations, expand application fields, and meet the growing needs of safety and health Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

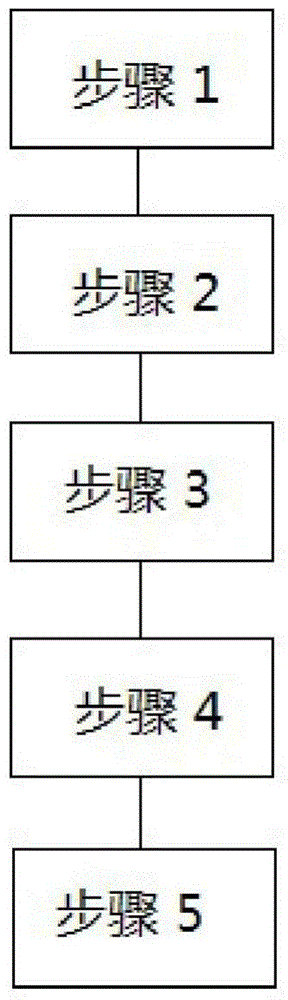

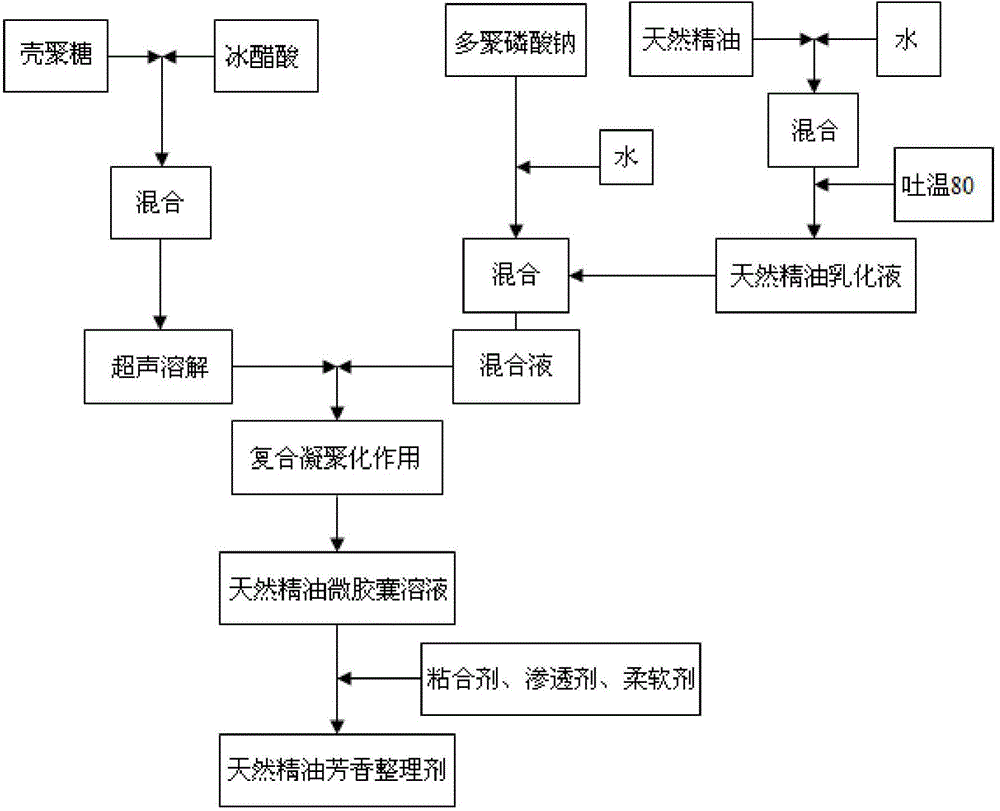

[0028] Reference figure 1 , figure 2 , A preparation method of natural essential oil fragrance finishing agent for silk fabrics, which specifically includes the following preparation steps:

[0029] 1) Add Tween 80 and natural essential oil in deionized water, and obtain a uniform natural essential oil emulsion after thorough stirring;

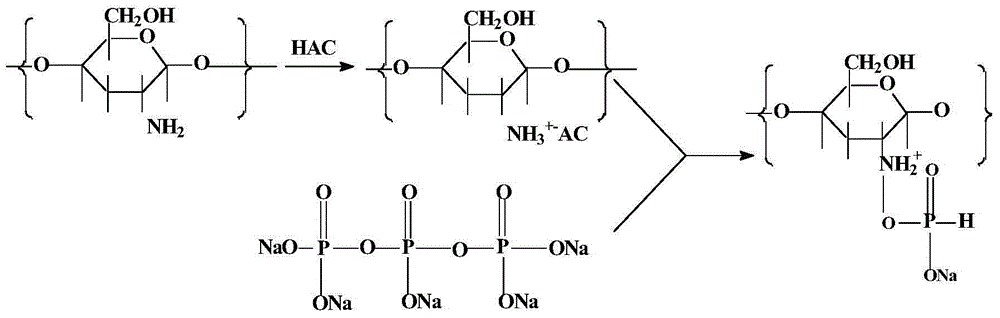

[0030] 2) Dissolve chitosan in glacial acetic acid solution, and obtain a transparent and uniform solution by ultrasonic degradation;

[0031] 3) Dissolve the sodium polyphosphate in deionized water until it is completely dissolved, then add the natural essential oil emulsion prepared in step 1), and stir thoroughly to obtain another homogeneous emulsion;

[0032] 4) Transfer the solution prepared in step 3) to an acid burette, and drop it into the transparent and uniform solution prepared in step 2) at the set drip rate under the action of magnetic stirring, and undergo a complex coagulation reaction Afterwards, a natural essential oil microcapsule...

Embodiment 1

[0034] Example 1: Lavender essential oil is selected as the core material, and the weight parts of the raw materials are 0.75 parts Tween 80, 0.75 parts lavender essential oil, 1.0 parts chitosan, 1.75 parts glacial acetic acid, 3.0 parts sodium polyphosphate, 6.0 parts by weight. Parts of adhesive, 2.0 parts of penetrant, 6.0 parts of softener, set the ultrasonic degradation time in step 2) to last 60 minutes, and the dripping rate in step 4) is 0.02ml~0.04ml every 3 seconds, according to step 1) ~4) Prepare the natural lavender essential oil microcapsule aqueous solution, and prepare the finished product according to step 5). The concentration of the natural lavender essential oil microcapsule aqueous solution in the finished product is 1.2%, and the balance is deionized water.

[0035] The natural lavender essential oil fragrance finishing agent prepared by the above preparation steps has a natural lavender smell, is non-toxic and harmless, soothes the mind, and is used for sil...

Embodiment 2

[0036] Example 2: Rose essential oil is selected as the core material, and the weight parts of the raw materials are 1.0 part Tween 80, 1.0 part rose essential oil, 1.2 parts chitosan, 2.1 parts glacial acetic acid, 3.6 parts sodium polyphosphate, 7.5 parts by weight. Parts of adhesive, 2.5 parts of penetrant, 7.5 parts of softener, set the ultrasonic degradation time in step 2) to last 70 minutes, and the drip rate in step 4) is 0.02ml~0.04ml every 3 seconds, according to step 1) ~4) Prepare the natural rose essential oil microcapsule aqueous solution, and prepare the finished product according to step 5). The concentration of the natural rose essential oil microcapsule aqueous solution in the finished product is 1.5%, and the balance is deionized water.

[0037] The natural rose essential oil fragrance finishing agent prepared by the above preparation steps has a natural rose smell, is rich and sweet, is non-toxic and harmless, makes people feel warm and happy, is used for silk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com