Automatic replacement device for multi-color bottom lines for computerized embroidery machine

An automatic replacement, embroidery machine technology, applied in the direction of embroidery machine mechanism, embroidery machine, textile and paper making, etc., can solve the problems of reducing equipment production efficiency, complex device structure, difficult to achieve, etc. Production efficiency, simple equipment structure, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

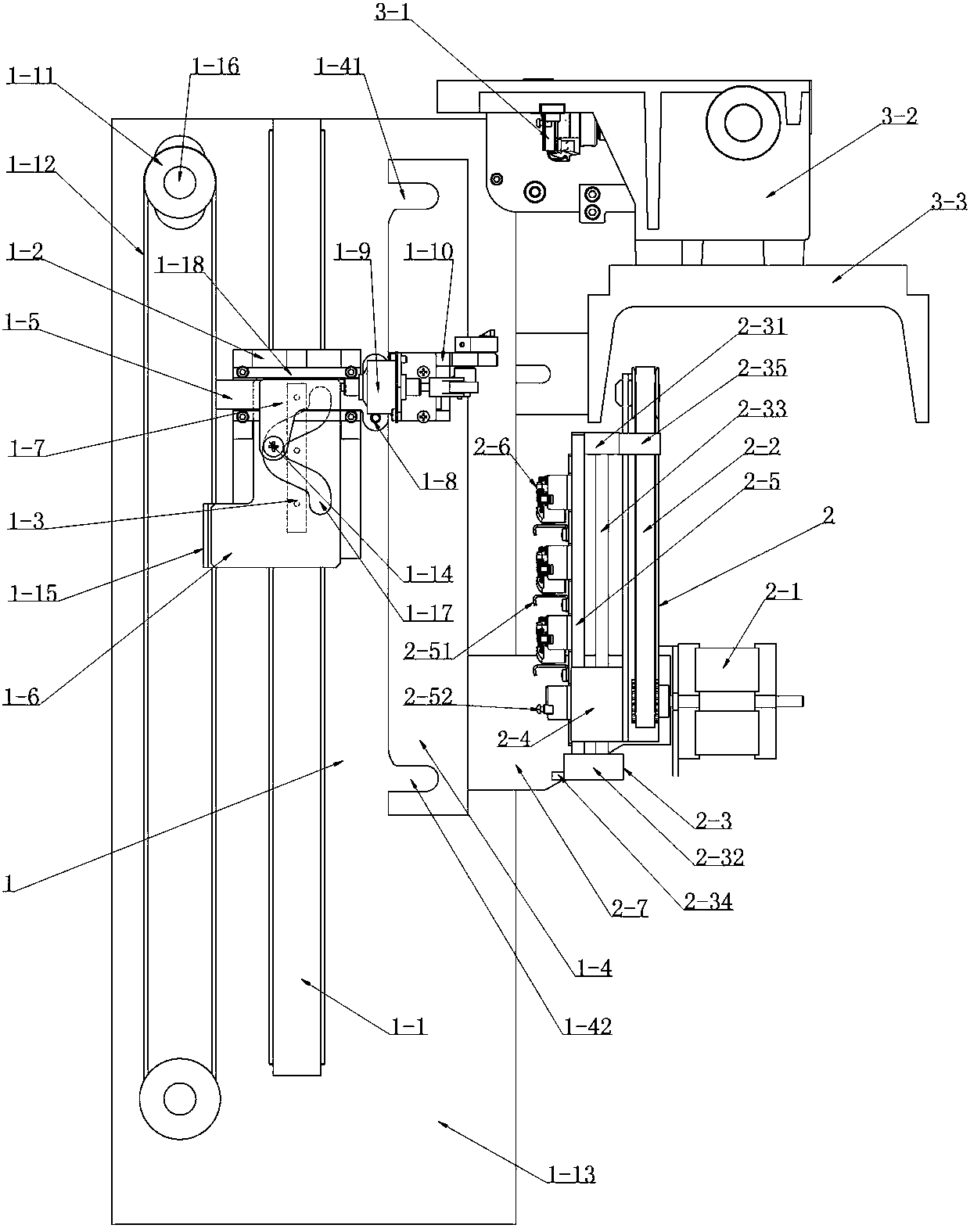

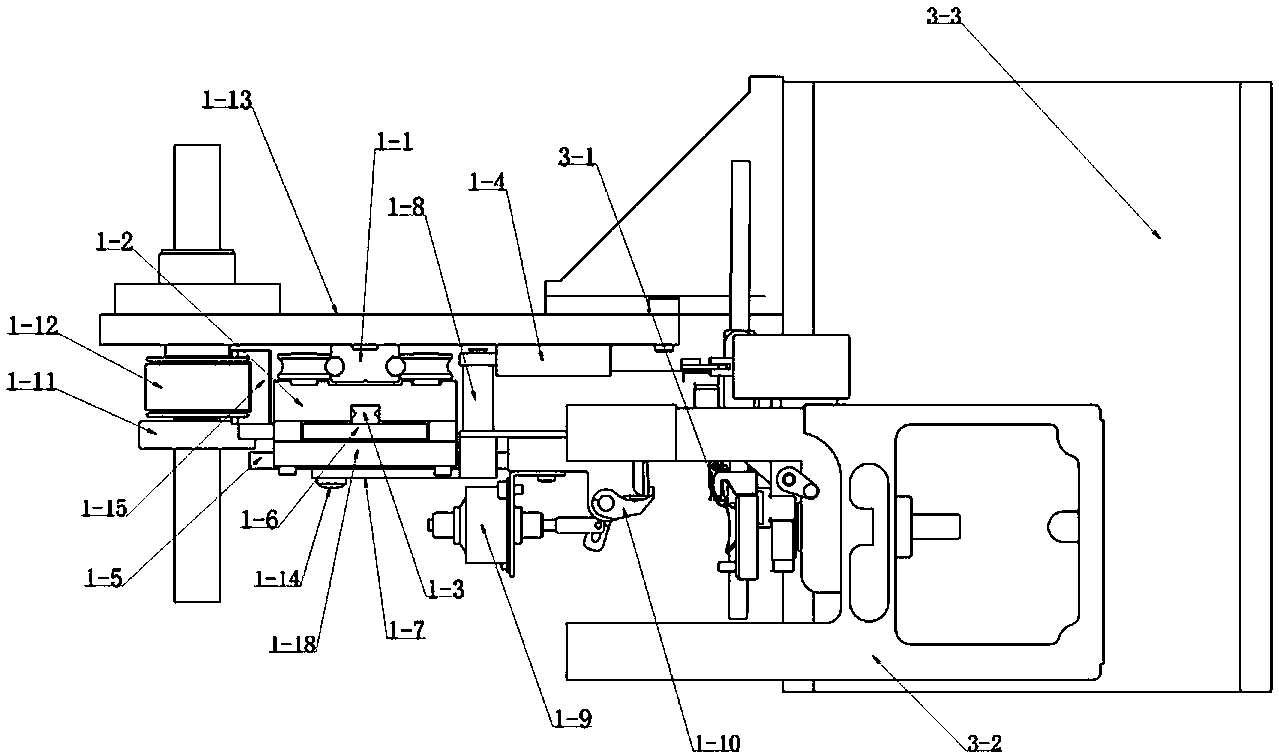

[0035] see figure 1 , figure 2 As shown, a multi-color bobbin bobbin automatic replacement device for a computerized embroidery machine consists of a mounting base plate 1-13, a rotary hook box 3-2, a rotary hook box seat 3-3, a transmission belt 1-12, and a guide rail 1-1 , limit plate 1-4, bobbin movement access mechanism 1, shuttle delivery mechanism 2 and program controller form. The installation base plate 1-13 is vertically placed on the left side of the rotary hook box seat 3-3 and is fixedly connected with the rotary hook box 3-2, and the rotary hook box 3-2 is fixed on the top of the rotary hook box seat 3-3, and the rotary hook box Seat 3-3 is fixed on the embroidery machine body, and bobbin 3-1 in use is housed in the rotary hook case 3-2, and whole set of devices is positioned at the below of embroidery machine workbench panel.

[0036] Vertical and parallel drive belts 1-12, guide rails 1-1 and limiting plates 1-4 are arranged from left to right on the mounting...

Embodiment 2

[0050] Stand-by shuttle row 2-5 among the present embodiment selects 13 bobbin seats 2-51 for use, and the size of parts related thereto needs to be adjusted adaptively, and all the other device structures are identical with embodiment 1.

[0051] There are 13 bobbin seats 2-51 on the standby shuttle row 2-5, and 12 bobbins from the 1st standby bobbin 2-6 to the 12th standby bobbin full of bottom threads of different colors are installed from bottom to top 2-6, the last bobbin seat 2-51 is used to place the first unloaded bobbin that has been replaced.

[0052] When replacing the bottom thread, take the hook claw mechanism 1-10 to take out the bobbin that was originally installed on the hook box 3-2 and put it on the bobbin seat left empty on the next shuttle row 2-5 2-51, after that, take out the first bobbin to be used and install it on the hook case 3-2. After the first bobbin for use is used up, put it back to its original bobbin seat 2-5 position, then take out the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com