A roll detection device suitable for chemical fiber equipment

A detection device and equipment technology, applied in the direction of cleaning methods using tools, complete sets of equipment for producing artificial threads, chemical instruments and methods, etc., can solve problems such as machine damage, machine installation space limitation, loss, etc., and achieve protection from damage , Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

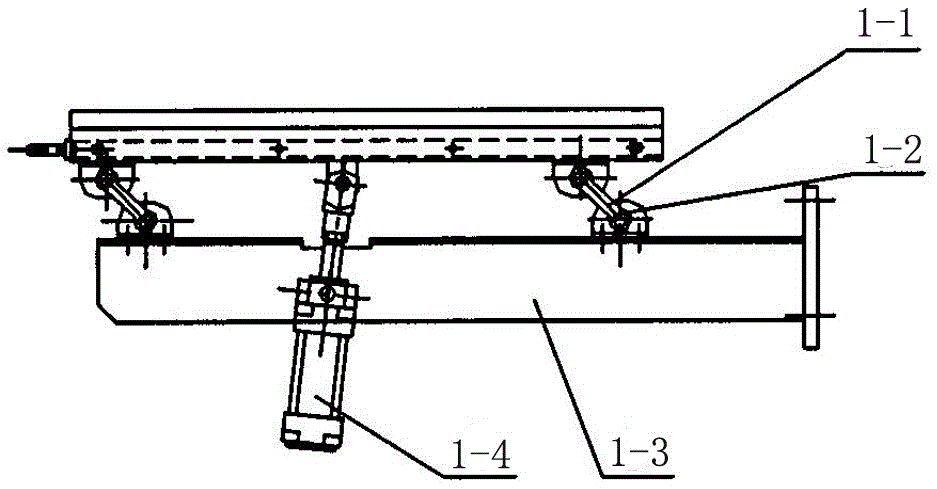

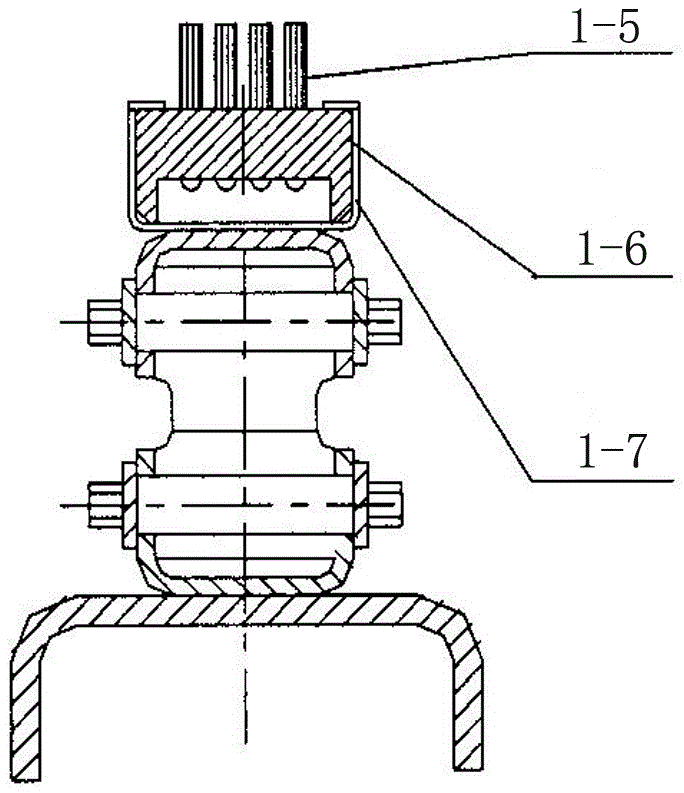

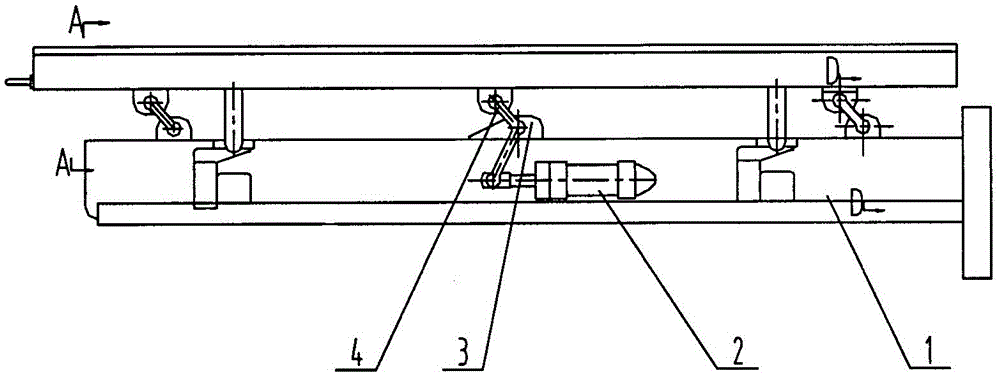

[0019] Such as image 3 , 4 , 5, the roll detection device suitable for chemical fiber equipment of the present invention includes a bracket 1, and the detection assembly arranged on the bracket passes through the front and rear connecting rods 9 and the front and rear connecting rods in a manner parallel to the bracket 1. The pendulum mechanism between them is installed on the track groove 8 above the bracket, the guide rail 7 embedded in the track groove 8, and the wooden pole 6 installed on the guide rail; The bottom surface of the groove 8 is hinged, and the bending part is composed of an L-shaped connecting rod 4 that is hinged between the support and the top surface of the bracket, and the lower end is hinged with the cylinder 2; the wooden rod 6 is a rod with a triangular cross-section. The two waists of the rod are covered with felt 5, and the wooden ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com