Arrow wine with black fruit and its preparation method

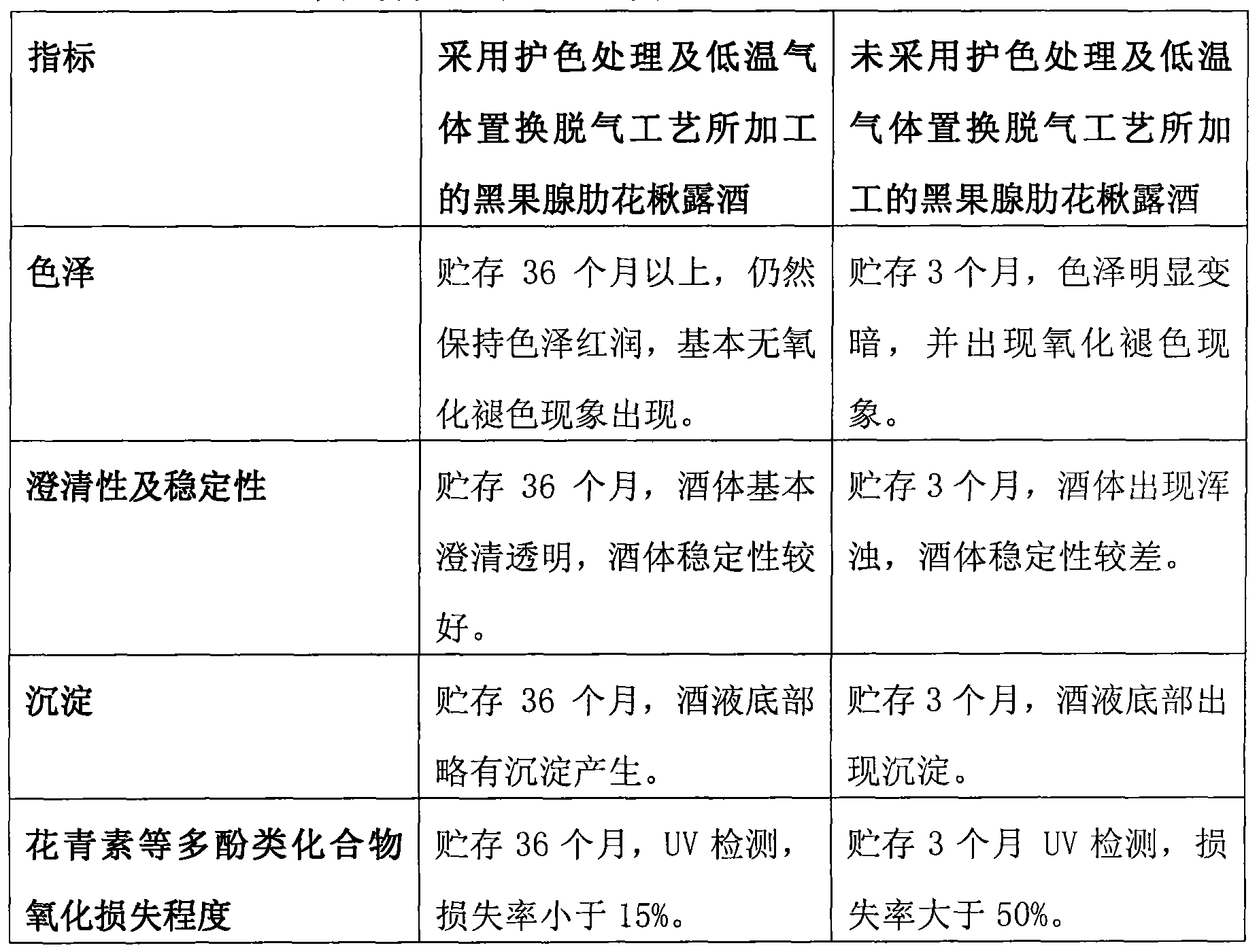

A technology of Aronia adenocarpa and dew wine, which is applied in the field of Aronia dew and its preparation, can solve the problems of easily oxidized extraction and difficult bioactive components, etc., and achieve clarification of wine body and prolongation of stability time, Prolong the fading time and solve the effect of wine fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Production process (raw material of fruit powder): Sorbus adenocarba fruit→selection→cleaning→draining→drying→crushing→sieving→leaching→filtering→secondary extraction of filter residue→two times of filtrate before mixing→alcoholicity Blending→color protection treatment→filtering→gas replacement degassing→filling→sealing→storage.

[0032] 1. Fruit selection: Remove rotten, moldy, spoiled, off-flavored fruits, leaves, stones, fruit stems and other impurities from the picked fruits.

[0033] 2. Cleaning and draining: Immerse the fruit in 3-4 times the clean water, stir it gently, keep it for more than 3 minutes, drain the dirty water, change the clean water to rinse 2-3 times, remove the fruit, drain and control to dry.

[0034] 3. Drying: the fruit is dried by natural drying or hot air drying, the drying temperature is lower than 65° C., and the water content (weight) of the dried fruit is 3-10%.

[0035] 4. Crushing and sieving: the dried fruit is crushed and sieved, an...

Embodiment 2

[0043] Production process (pomace raw material): Sorbus adenocarba fruit→selection→cleaning→draining→juicing→pomace drying→crushing→sieving→leaching→filtering→secondary extraction of filter residue→mixing filtrate→ Alcohol blending→color protection treatment→filtering→gas replacement degassing→filling→sealing→storage.

[0044] 1. Fruit selection: Remove rotten, moldy, spoiled, off-flavored fruits, leaves, stones, fruit stems and other impurities from the picked fruits.

[0045] 2. Cleaning and juicing: Immerse the fruit in 3-4 times the clean water, stir it gently, keep it for more than 3 minutes, let go of the dirty water, change the clean water to rinse 2-3 times, remove the fruit, drain and dry; use a screw press The juicer squeezes the juice from the fruit.

[0046] 3. Pomace drying: Dry the pomace separated after juicing by natural drying or hot air drying, and the drying temperature is lower than 65°C. The moisture content (weight) of the pomace after drying is 3-10%. ...

Embodiment 3

[0055] Production process (juice raw materials): Sorbus adenocarba fruit→selection→cleaning→draining→juicing→removing glue→juice color protection treatment→alcohol blending→filtering→gas replacement degassing→filling→sealing→ storage.

[0056] 1. Fruit selection: Remove rotten, moldy, spoiled, off-flavored fruits, leaves, stones, fruit stems and other impurities from the picked fruits.

[0057] 2. Cleaning and juicing: Immerse the fruit in 3-4 times the clean water, stir it gently, keep it for more than 3 minutes, let go of the dirty water, change the clean water to rinse 2-3 times, remove the fruit, drain the water and control it dry, use a screw The juicer extracts the juice from the fruit.

[0058] 3. Gum removal and color protection treatment: add 0.1-0.5g / L pectinase to the fruit juice, keep warm at 45-50°C for 2 hours; then add 0.1-0.15g / L sulfur dioxide, 0.15-0.2g / L isoVC Sodium (sodium erythorbate) for color protection of the juice.

[0059] 4. Alcohol blending and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com