Automatic rotation type coke cutter

A technology of coke cutter and governor, which is applied in coke oven, petroleum industry, cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

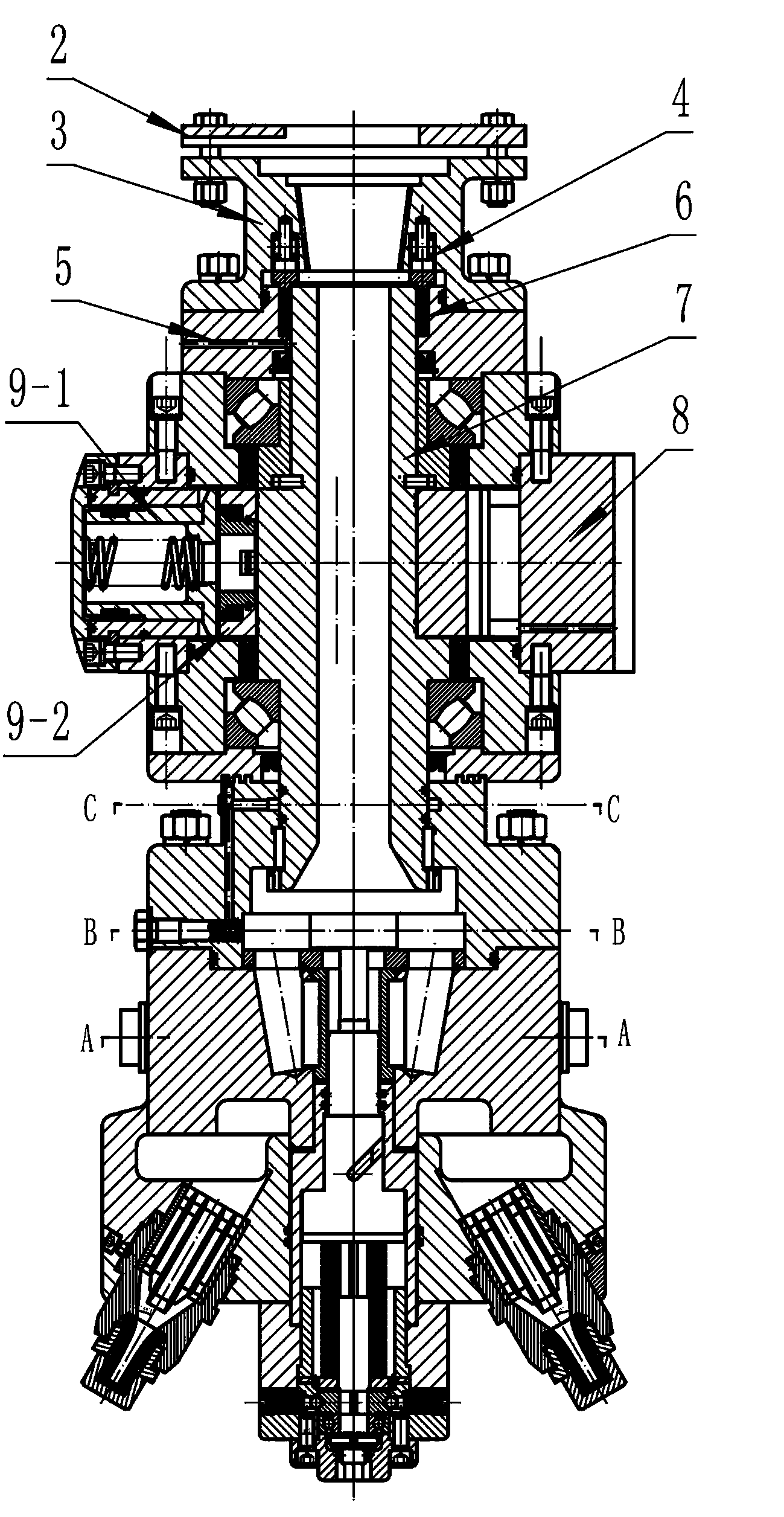

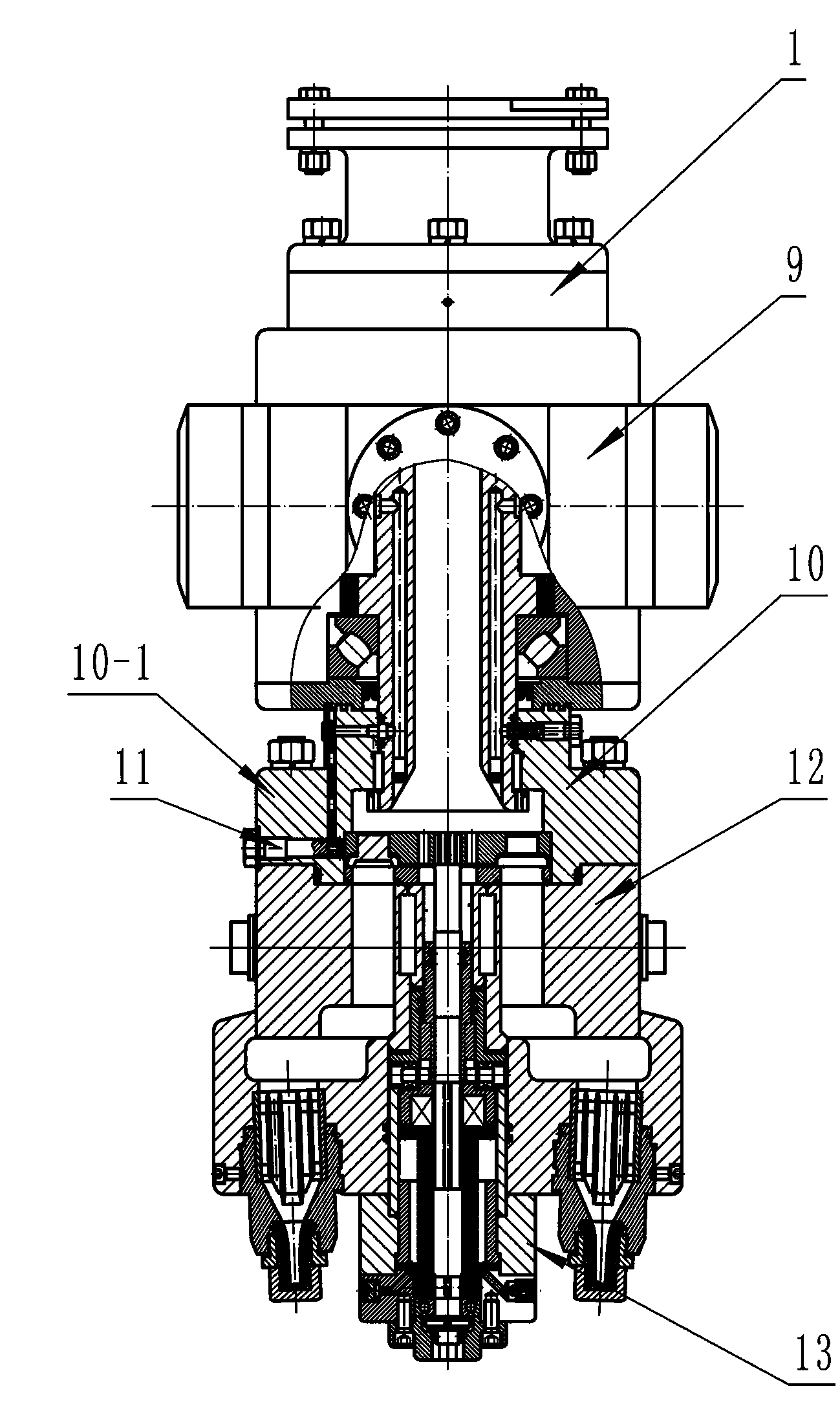

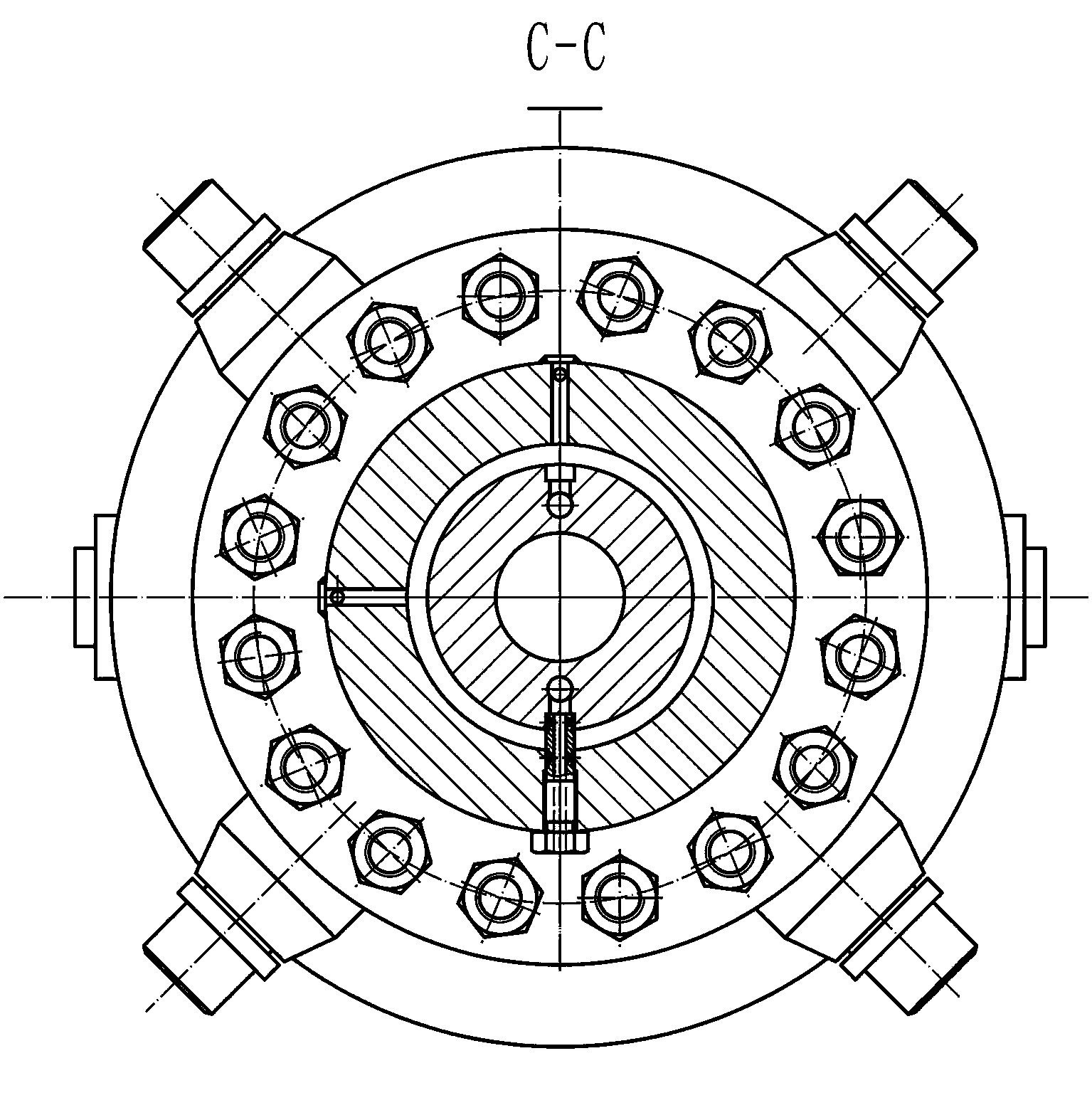

[0018] Such as Figure 1 to Figure 7 shown. The present invention consists of a drill pipe connecting part 1 , a hydrodynamic part 9 , a decoking part 12 , a throttling speed regulating part 10 and a switching part 13 to form a self-rotating coke cutter. From top to bottom, the drill pipe connecting part 1 is connected to the hydrodynamic part 9, the throttling speed regulating part 10 is arranged between the hydrodynamic part 9 and the decoking part 12, and the switching part 13 is located in the axial cavity of the decoking part 12 .

[0019] The drill pipe connecting part 1 is composed of an anti-loosening flange 2 , a connecting seat 3 , an elastic element 4 , a sealing seat 5 and a sealing element 6 . The uppermost end of the drill pipe connecting part 1 is the anti-loosening flange 2, the anti-loosening flange 2 is connected with the connecting seat 3 through bolts, the through-hole thread of the connecting seat 3 is connected with the drill pipe, the connecting seat 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com