Packaging box applicable to frame-free assembly

A packaging box and frame component technology, which is applied in the direction of transportation and packaging, external accessories, containers to prevent mechanical damage, etc., can solve the problems of stacking components, inconvenient operation, and rising packaging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

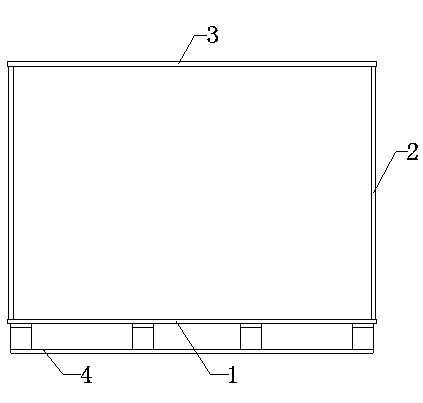

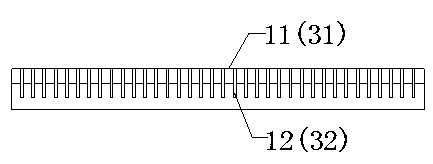

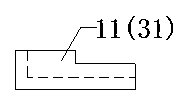

[0024] Such as Figure 1-7 As shown, a packing box suitable for frameless components includes a bottom plate 1 and side plates 2 arranged around the bottom plate 1. The bottom plate 1 and the side plates 2 together form a box structure; the bottom plate 1 is provided with two first The positioning portion 11 has first positioning grooves 12 evenly distributed on the first positioning portion 11 . The first positioning part 11 and the base plate 1 can be fixedly connected by glue or detachably connected; in addition, in this embodiment, the cross section of the first positioning part 11 is stepped, which can effectively save the production cost; The bottom surface is also provided with a pallet 4 for supporting the whole packing box.

[0025] In order to better position the components, the side plate 2 perpendicular to the first positioning groove 12 is also provided with a second positioning part 21 on the inner wall of one of the side plates 2, which is located in the middle...

Embodiment 2

[0028] The rest is the same as the above embodiment, except that there are three first positioning parts 11 arranged on the base plate 1, two of which are located on both sides of the base plate 1, and one of them is located in the middle.

Embodiment 3

[0030] The rest is the same as the above embodiment, except that the inner walls of the two side plates 2 perpendicular to the first positioning groove 12 are provided with the second positioning portion 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com