Tray positioning push part of lower box mechanism

A technology of tray trays and lower boxes, which is applied in the direction of conveyor objects, conveyors, transportation and packaging, etc., can solve the problem that the lower box mechanism cannot be used for common transmission mechanisms, and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

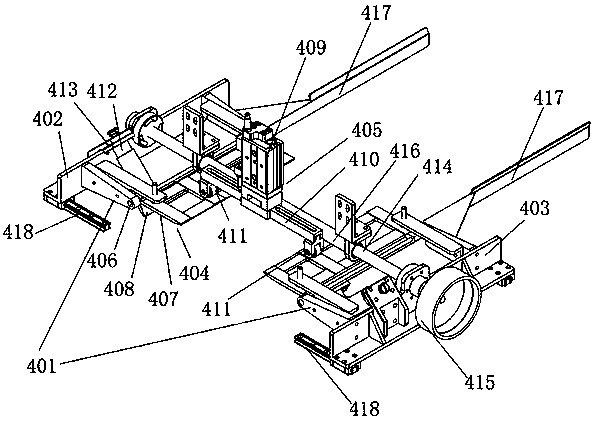

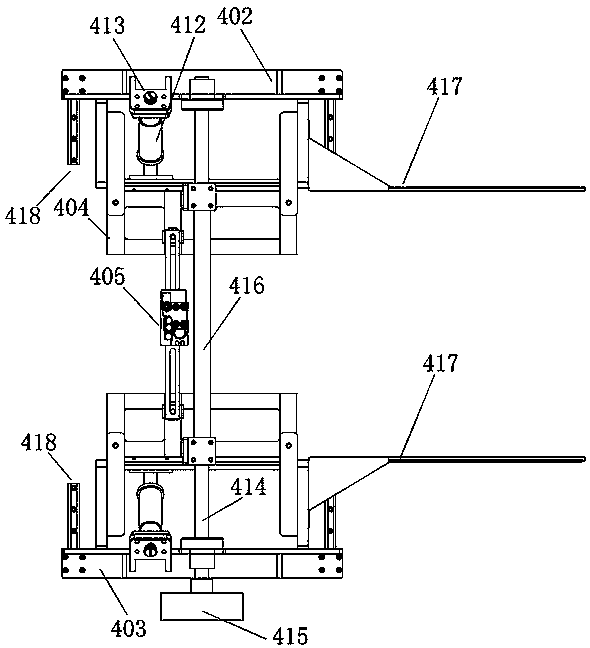

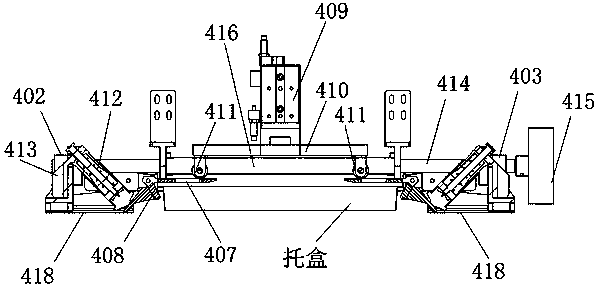

[0034]The bracket positioning push part of the lower box mechanism includes a positioning mounting bracket 401, and the positioning mounting bracket 401 includes a left bracket 402 and a right bracket 403, and the inner sides of the left bracket 402 and the right bracket 403 are each provided with a bracket for supporting the bracket. Cartridge card slot 404, the two tray card slots 404 are symmetrically arranged, and the openings of the two symmetrically arranged tray card slots 404 are parallel to each other, and a pressing device for pushing down the tray box is arranged above the tray card slot 404 405 , the tray slot 404 is connected to the positioning installation frame 401 through the slot rotation shaft 406 . The left support 402 and the right support 403 are respectively provided with a tray draw-in slot 404, and the tray tray is positioned between the two tray draw-in slots 404, and the tray tray is supported by the two tray draw-in slots 404, and now the pressing dev...

Embodiment 2

[0036] The bracket positioning push part of the lower box mechanism includes a positioning mounting bracket 401, and the positioning mounting bracket 401 includes a left bracket 402 and a right bracket 403, and the inner sides of the left bracket 402 and the right bracket 403 are each provided with a bracket for supporting the bracket. Cartridge card slot 404, the two tray card slots 404 are symmetrically arranged, and the openings of the two symmetrically arranged tray card slots 404 are parallel to each other, and a pressing device for pushing down the tray box is arranged above the tray card slot 404 405 , the tray slot 404 is connected to the positioning installation frame 401 through the slot rotation shaft 406 .

[0037] The tray draw-in slot 404 comprises a draw-in slot horizontal plate 407 and a draw-in slot slant plate 408 fixedly connected. The slant plate 408 and the card slot are connected to the installation frame through the card slot rotating shaft 406 at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com