Tool piece and process for assembling Z-axis lead screw of laser cutting machine

A technology for laser cutting machines and tooling parts, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problem that it is difficult for operators to install and fix screw rods, it takes a day or even longer, and wastes operator time, etc. Problems, to achieve the effect of convenient and quick manufacturing and installation, lower maintenance and maintenance costs, compact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

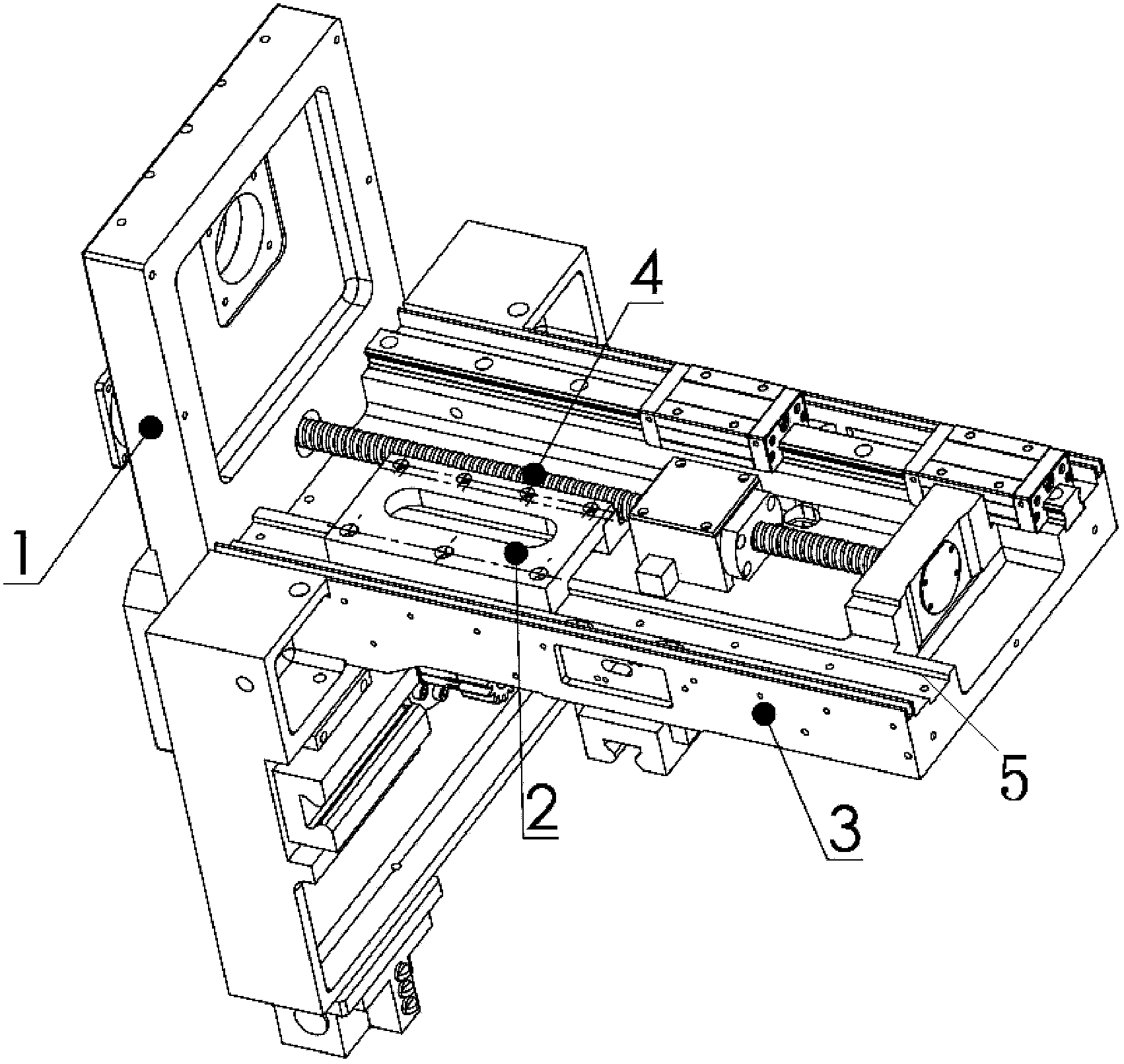

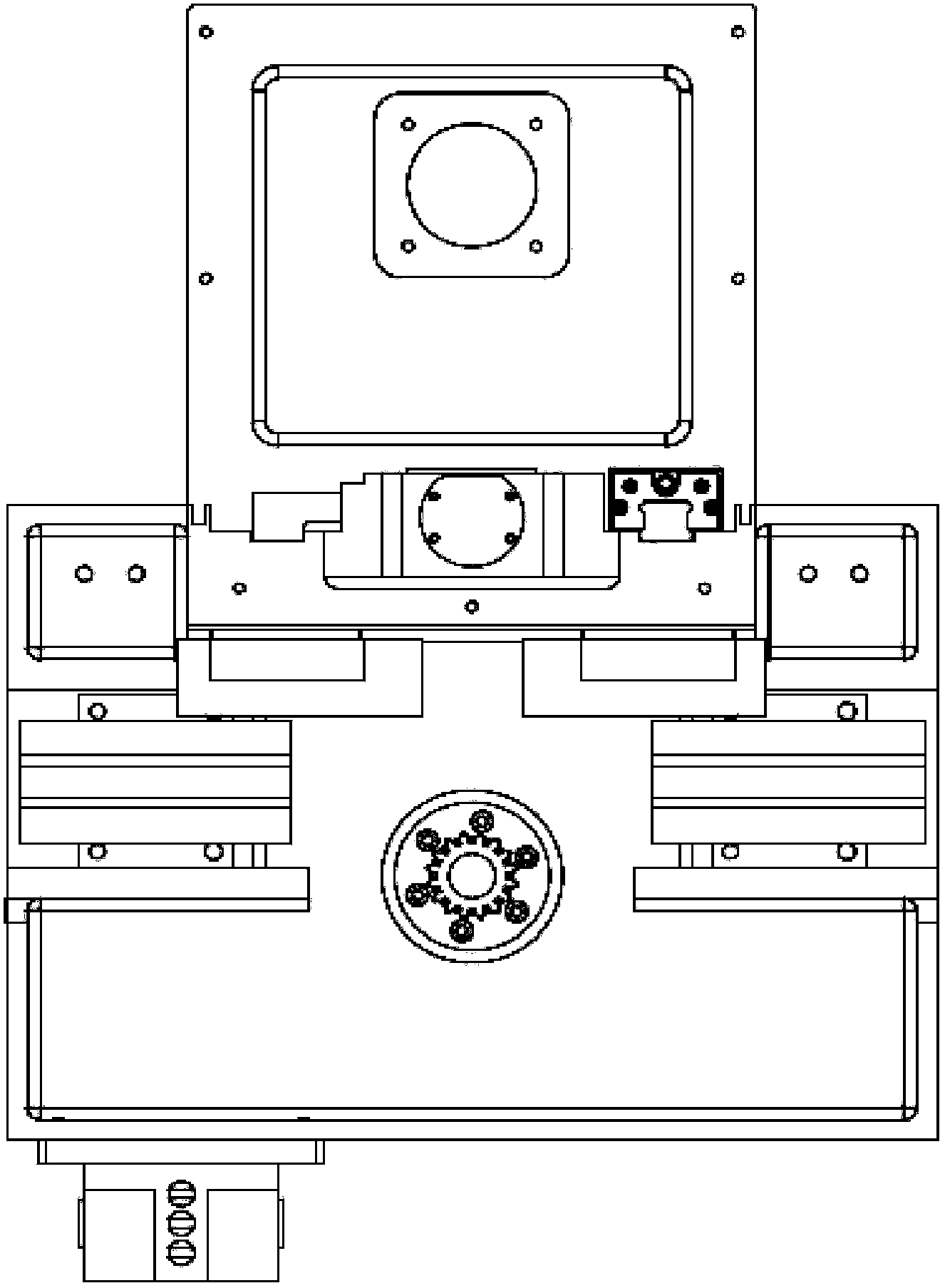

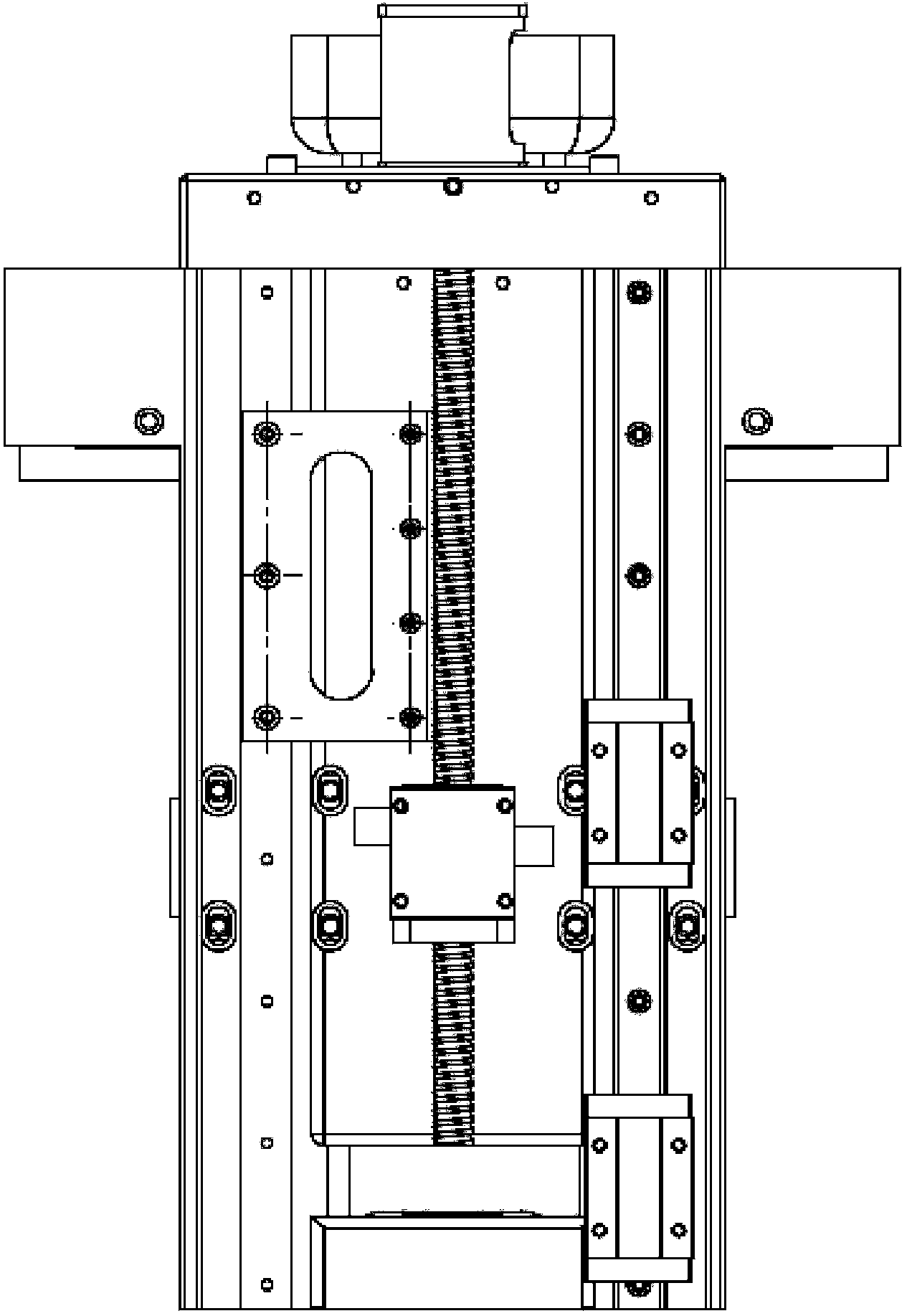

[0021] See attached Figure 1-4 :

[0022] The invention is an assembly tooling for the Z-axis screw rod of a laser cutting machine. It is composed of an L-shaped angle steel piece with two mutually perpendicular surfaces and a rectangular body with a stepped cross section. The left side of the rectangular body is provided with For positioning screw holes, the right side of the rectangular body is provided with a connecting screw hole, the center of the rectangular body is provided with a groove, and the edge of the rectangular body is connected with the L-shaped angle steel by screws.

[0023] The assembly process of the Z-axis screw of a laser cutting machine of the present invention has the following steps:

[0024] 1) Install the lower edge of the left side of the rectangular body on the linear guide rail of the laser cutting machine, fix the rectangular body with 3 screws, and make the rectangular body close to the linear guide rail by the top screw on the side of the sliding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com