DPM (direct part mark) two-dimensional code recognition system

A technology of two-dimensional code and pneumatic system, applied in the field of DPM two-dimensional code recognition system, which can solve the problems of large size, consumption and inconvenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

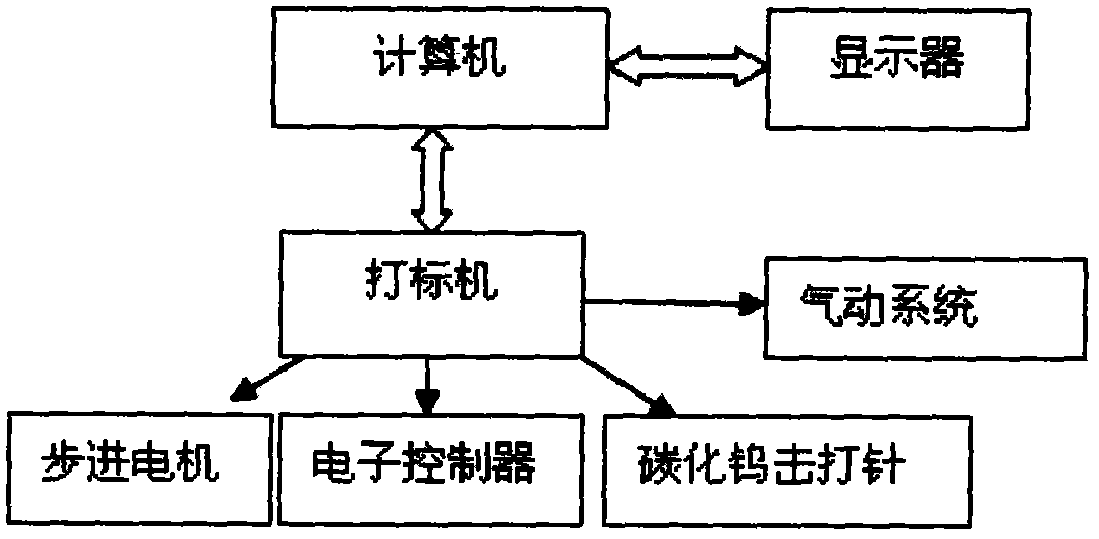

[0053] DPM encoding equipment

[0054] The encoding equipment is composed of computer, monitor and marking machine. Under the control of the computer, the marking machine moves in the plane through the two-dimensional workbench, and at the same time, the needle head vibrates at high frequency through the pneumatic system to print a clear DPM two-dimensional code mark on the workpiece. The marking machine equipment is mainly composed of three parts: pneumatic system, stepping motor, electronic controller and tungsten carbide needle. The electronic controller is the core component of the coding equipment, mainly used to control the up and down movement of the tungsten carbide needle. Deep and shallow dents are formed on the surface to form a DPM QR code. The function of the stepper motor is to drive the injection movement and control the direction and precision of the movement. The hardware design block diagram of the encoding device is as follows figure 1 shown.

Embodiment 2

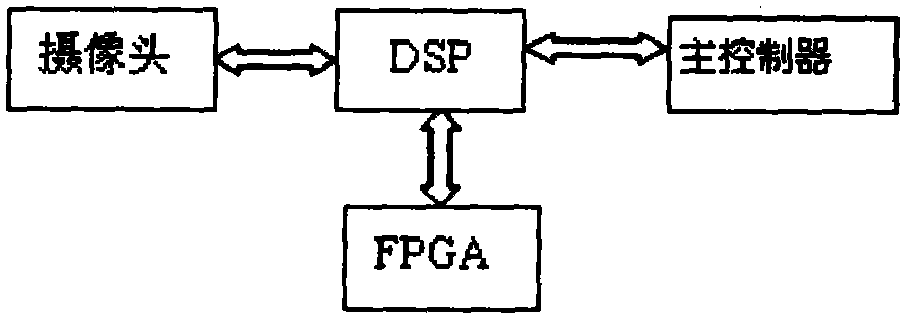

[0056] DPM two-dimensional code automatic identification platform

[0057]DPM two-dimensional code target image acquisition and preprocessing are mainly realized by digital signal processor (DSP) and field programmable gate array (FPGA), and the master / slave mode is adopted between DSP and FPGA. Among them, the DSP mainly completes the processing of the target image and controls the start of the FPGA sampling signal. FPGA completes the sampling control process of the target image. ARM (Acorn RISC Machine) 9 or ARM11 processor is used to complete the positioning and recognition of the collected DPM two-dimensional code target image.

[0058] The target image acquisition and processing module composed of DSP and FPGA transmits the image target to be recognized to the DSP through the camera, and the DSP completes the preprocessing and distortion processing of the target image, and uniformly converts the image into a grayscale image. Then, the DSP inputs the processed target ima...

Embodiment 3

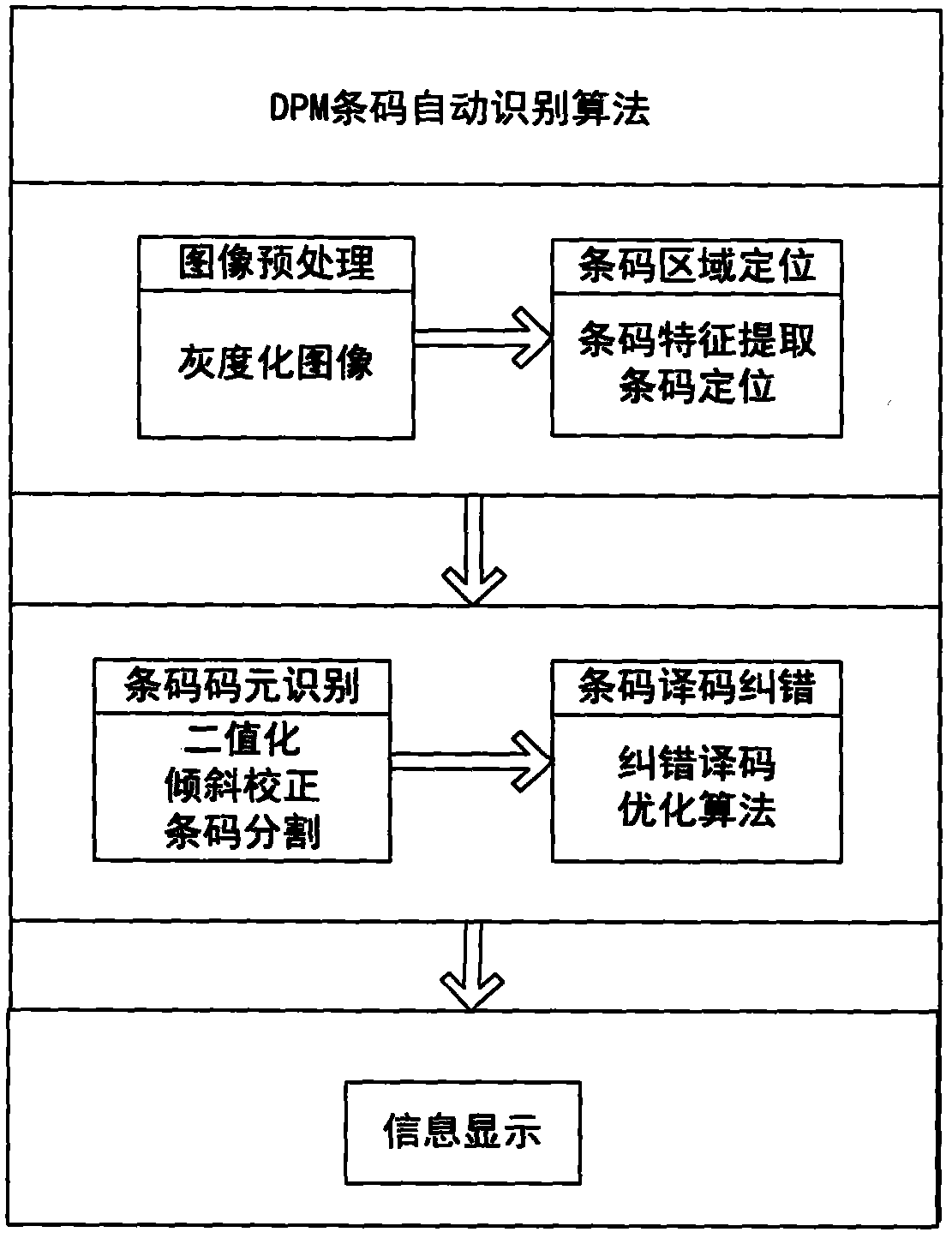

[0060] DPM two-dimensional code automatic recognition method

[0061] The method flow involved in automatic recognition of DPM barcodes can be divided into the following steps: barcode image acquisition, image preprocessing, barcode area positioning, two-dimensional code element precise positioning algorithm, barcode decoding error correction, and result display. The invention adopts the identification algorithm technology with independent intellectual property rights, can quickly locate the area of the two-dimensional code, divide the internal code elements of the two-dimensional code, and make up for the defect phenomenon through the decoding error correction algorithm. Compared with traditional algorithms, it has obvious advantages in recognition rate and recognition time. image 3 is a flowchart of the automatic identification method.

[0062] (1) Image preprocessing

[0063] Image preprocessing mainly refers to the grayscale transformation of the image, and the weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com