Interactive semi-automatic grating surface defect detection device and method using device

A defect detection and semi-automatic technology, which is applied in the direction of optical defect/defect detection, can solve the problems of low detection accuracy, poor anti-interference, and low detection efficiency, and achieve strong anti-interference, good shock absorption, and high detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

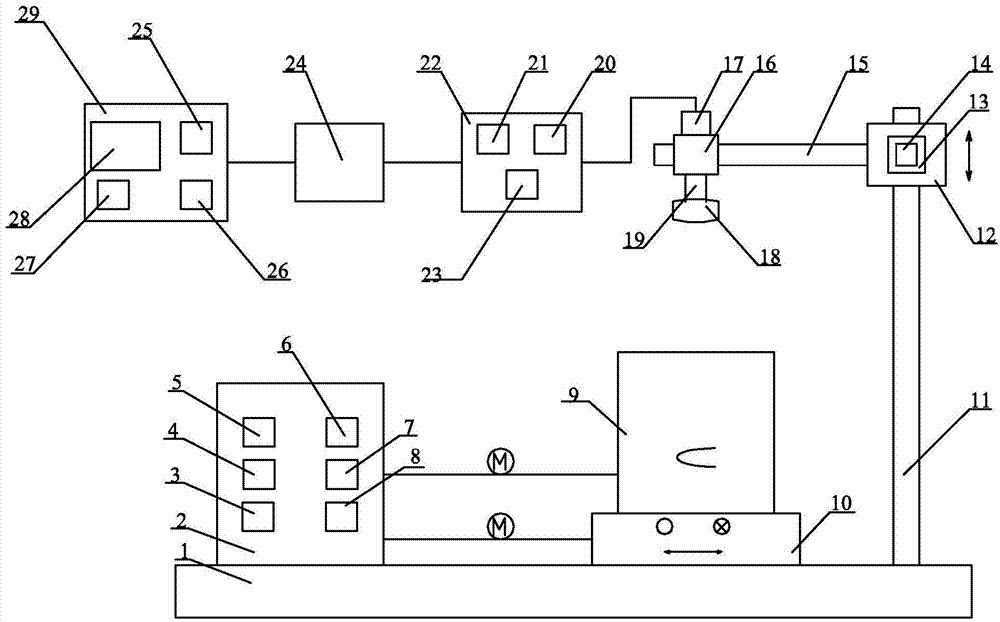

[0032] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, this embodiment includes detection workbench 1, described surface defect detection device also includes motion control cabinet 2, grating surface unfolding unit, first image acquisition system unit and second image acquisition system unit, motion control cabinet 2 , the grating surface expansion unit and the first image acquisition system unit are arranged side by side on the detection workbench 1 from left to right, the second image acquisition system unit is connected with the first image acquisition system unit,

[0033] The motion control cabinet 2 includes a safety protection assembly 3, a parameter input device 4, a numerical display 5, a light source controller 6, a rotation controller 7 and a displacement controller 8, and the safety protection assembly 3, the parameter input device 4 and the numerical display 5 are composed of The light source controller 6, the rotation contr...

specific Embodiment approach 2

[0044] Specific implementation mode two: combination figure 1 and figure 2 The present embodiment is described. The grating unfolding mechanism 9 of the present embodiment includes a box body and a transmission light source, and the transmission light source is arranged on the box body. This is set up for ease of use. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

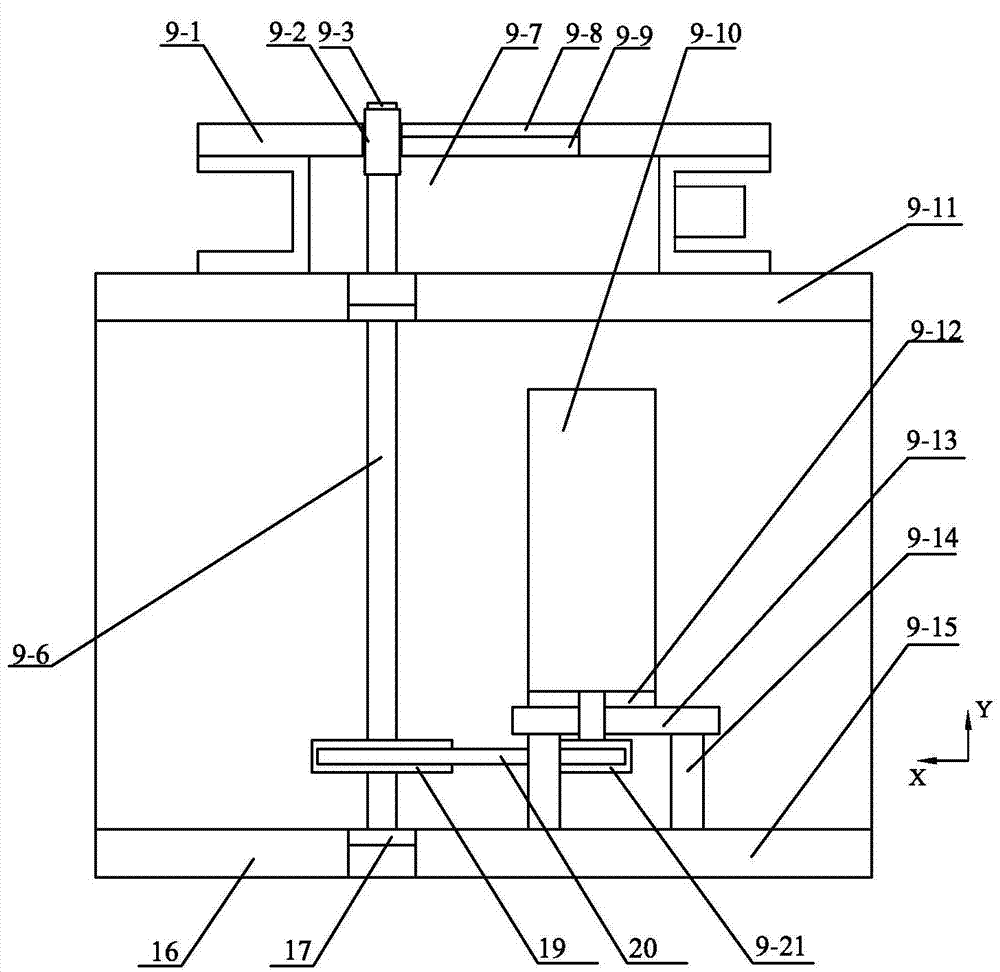

[0045]Specific implementation mode three: combination figure 2 Describe this embodiment, the box of this embodiment includes quick-change fixture group 9-2, upper miniature bearing 9-4, shaft 9-6, servo motor 9-10, box top plate 9-11, spacer 9-12 , Motor support plate 9-13, box shell 9-15, box bottom plate 9-16, lower miniature bearing 9-17, synchronous large pulley 9-19, tension synchronous belt 9-20, synchronous small pulley 9-21 and a plurality of motor support columns 9-14,

[0046] Casing top plate 9-11 and casing bottom plate 9-16 are respectively arranged on the upper and lower ends of casing shell 9-15, and shaft 9-6 is vertically arranged in casing casing 9-15, and the two ends of shaft 9-6 An upper miniature bearing 9-4 and a lower miniature bearing 9-17 are arranged at the upper end respectively, the quick-change clamp group 9-2 is arranged on the upper end of the shaft 9-6, and a plurality of motor support columns 9-14 are arranged on one side of the shaft 9-6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com