Optical fiber type on-line real-time pantograph lifting pressure detection system

A technology of pantograph and pantograph carbon slide plate, which is applied in the measurement of the change force of the optical properties of the material when it is stressed, can solve the problems that the detection of pressure value changes cannot be realized, and achieve good insulation, Easy to install, anti-electromagnetic interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

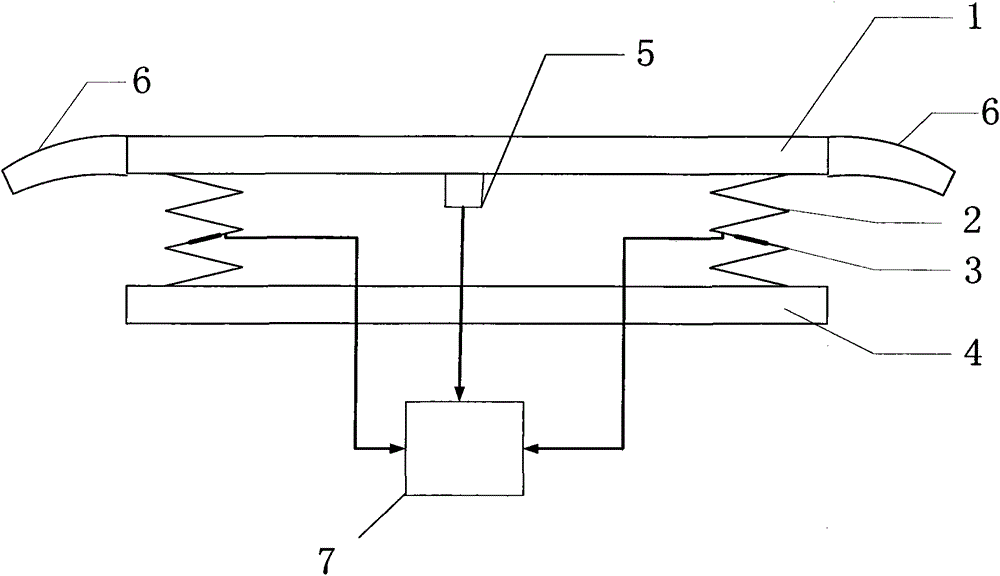

[0021] Such as figure 1 As shown, the fiber-optic pantograph jacking pressure online real-time detection system of this embodiment includes a pantograph carbon slide [1], an elastic plate [2], an optical fiber strain sensor [3], a carbon slide bracket [4], Fiber optic accelerometer [5], horn [6], and signal processing unit [7].

[0022] The optical fiber strain sensor [3] is used to measure the elastic strain of the elastic plate [2] to calculate the section force value F d .

[0023] The fiber optic accelerometer [5] is used to measure the inertial force F of the pantograph ine .

[0024] The pantograph carbon skateboard [1] and the carbon skateboard bracket [4] are supported and connected by the elastic plate [2], the optical fiber strain sensor [3] is pasted on the elastic plate [2], and the optical fiber accelerometer [7] is installed on the pantograph The lower surface of the carbon slide [1], the signal processing unit [5] is connected to the fiber optic strain senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com