A high-precision constant force hanging device

A hanging device, high-precision technology, applied in the direction of load hanging components, transportation and packaging, bearings, etc., can solve the problems of difficult to achieve large-quality hanging, unstable hanging force, and low precision of constant force hanging, etc. Achieve the effect of simple structure and gas supply mode, simple structure, and sudden change in volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

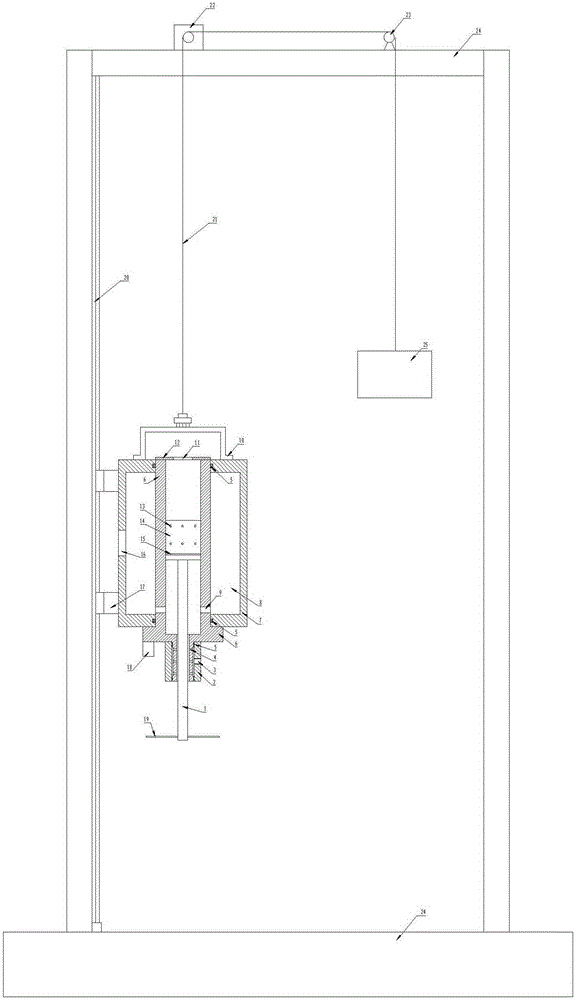

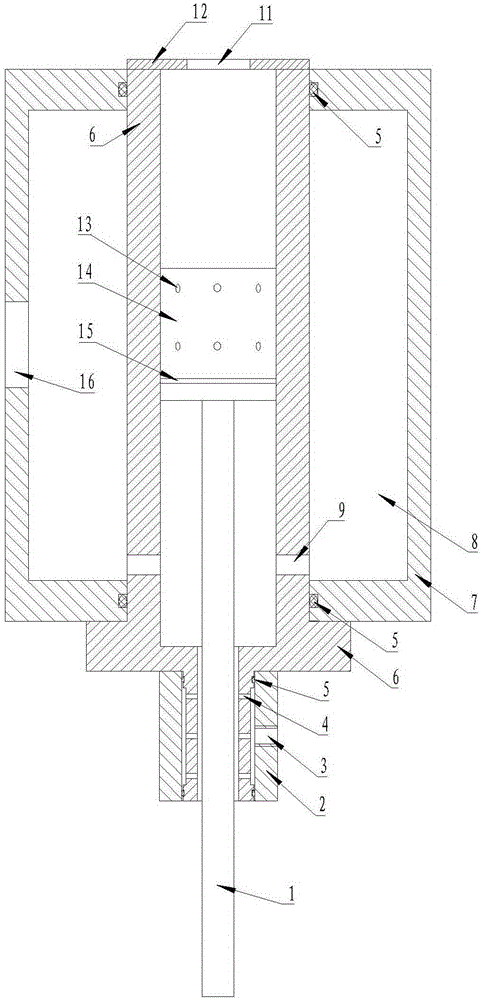

[0021] A high-precision constant-force hanging device includes a counterweight 25 , a motor 22 , a suspension rope 21 , an output cylinder, a linear guide rail 20 , a laser displacement sensor 18 , a reflector 19 , and a bracket 24 . The side of the output cylinder is connected to the linear guide rail 20 in the vertical direction through the slide block 17, the top of the cylinder barrel of the output cylinder is connected to the motor 22 by the suspension rope 21, the motor 22 is installed on the support 24, and the fixed position is installed on the support 24. The pulley 23, the suspension rope 21 is wound on the output shaft of the motor, and finally the counterweight 25 is connected with the fixed pulley 23.

[0022] The output cylinder includes a cylinder 6, a piston 14, an output shaft 1, and an air storage sleeve 7; the air storage sleeve 7 is set outside the cylinder 6 and forms an air storage chamber 8 with the cylinder, and the piston 14 is set on There is a very s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com