Novel waterproof board laying construction method

A technology of waterproofing board and construction method, applied in mining equipment, shaft lining, tunnel lining and other directions, can solve the problems of high requirements for operators' hot-melt welding technology, easy to damage the integrity of waterproofing board, complicated laying method and process, etc., to simplify laying The effect of operating technology, ensuring laying quality and saving laying costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

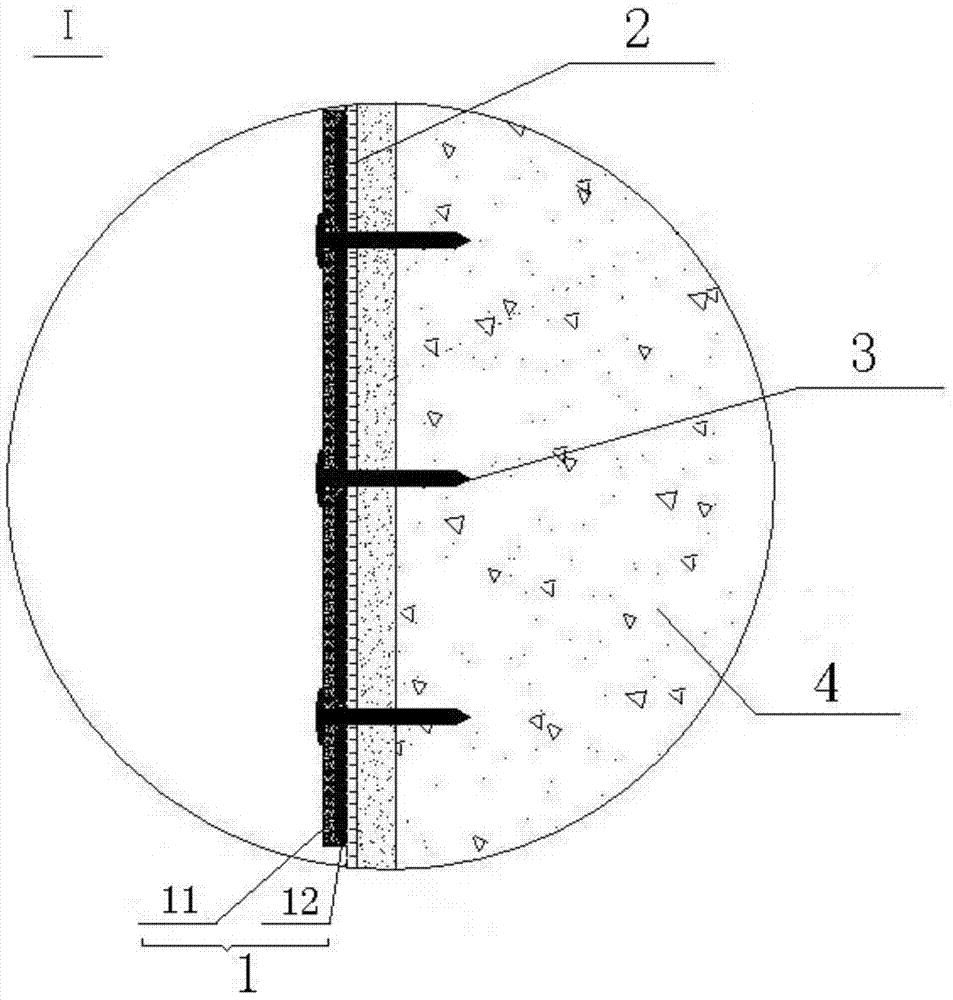

[0039] The new construction method for laying waterproof boards of the present invention uses the mother-child buckle to complete the laying of the waterproof board on the tunnel excavation contour; Hook 11, the other side is EVA rubber sheet 12, the organic hook 11 and the EVA rubber sheet 12 are integrally formed; one side of the mother sheet 5 is organic silk, the other side is coated with hot-melt adhesive, and the hot-melt adhesive peripheral There is a protective film 6; as shown in Figures 1 to 4, the new method of laying waterproof boards includes the following steps:

[0040] (1) Fix the sub-sheet 1 and the geotextile 2 on the sprayed concrete surface 4 of the tunnel excavation outline with nails 3, the organic hook 11 faces outward, the EVA rubber sheet 12 is in contact with the geotextile 2, and the geotextile 2 is in contact with the tunnel excavation. Digging profile sprayed concrete surface 4 contacts; As shown in Figure 1, Figure 1 (a) is a schematic diagram of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com