Downhole three-phase separating device

A technology of three-phase separation and outer pipe, which is applied in the direction of wellbore/well components, cleaning equipment, production fluid, etc., and can solve the problems of short protection distance, limited protection distance, shortened protection time and crude oil separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

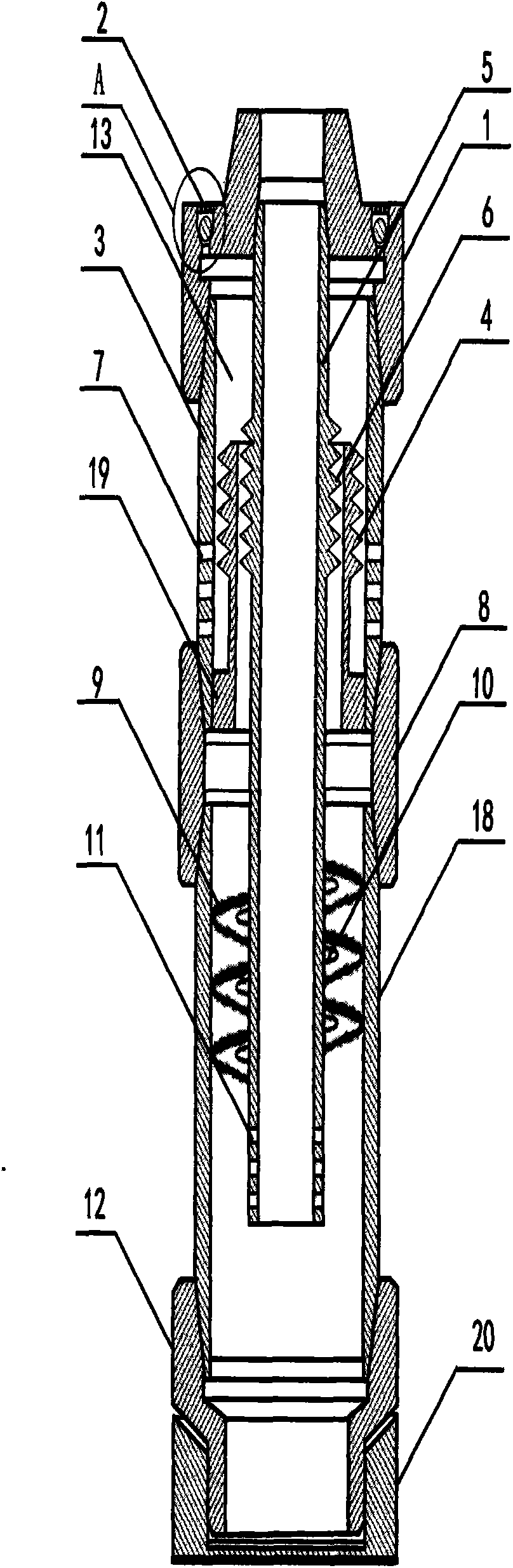

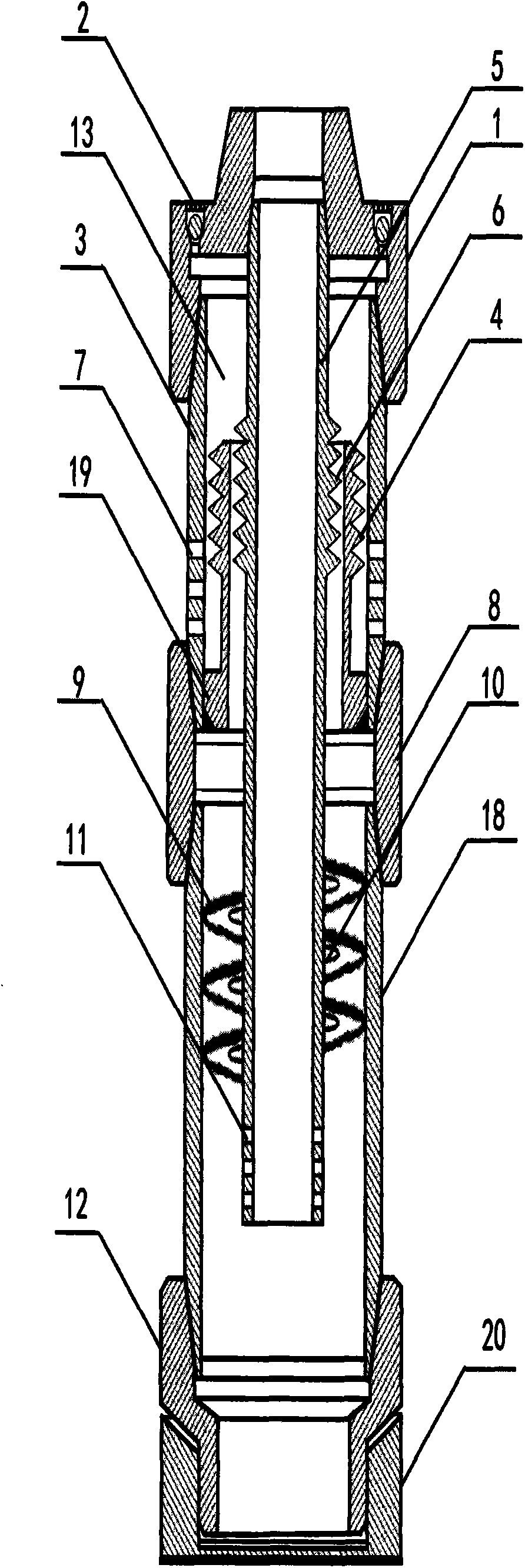

[0018] Since the present invention is composed of a gas-liquid separation grit setting module and a wax-proof, anti-scaling and anti-corrosion module, the specific embodiments of the gas-liquid separation and grit setting module, the wax-proof, anti-scaling and anti-corrosion module will be described below in conjunction with the accompanying drawings.

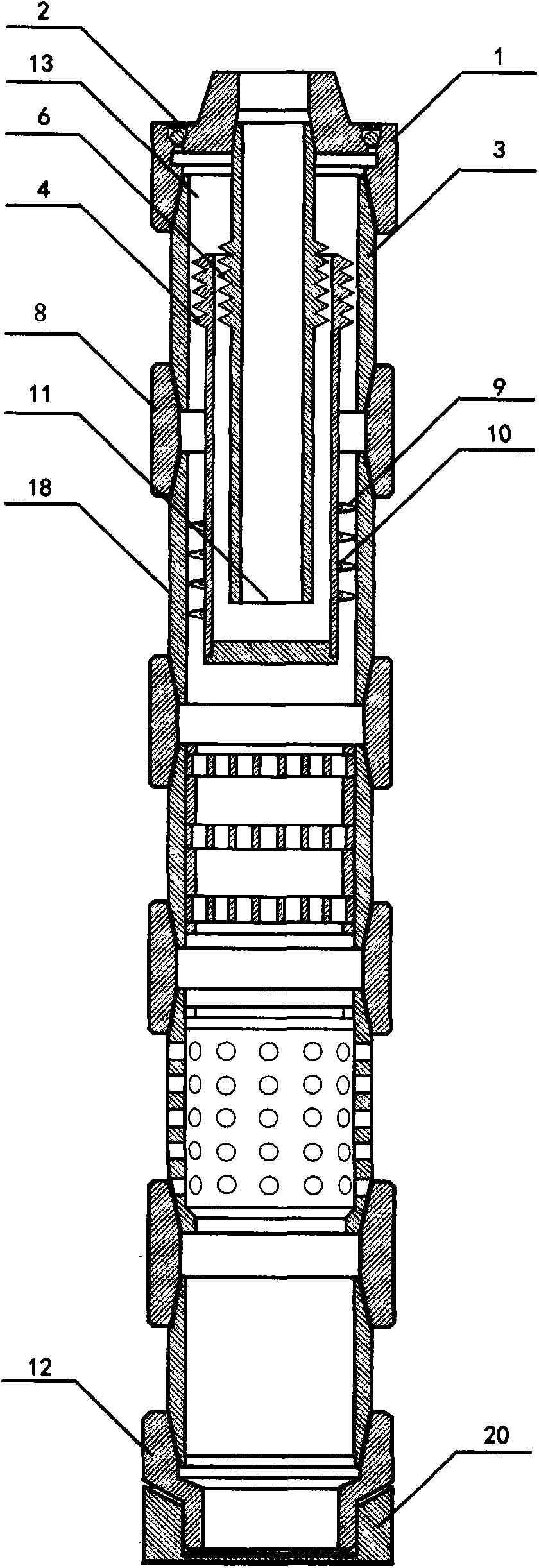

[0019] The first embodiment of the gas-liquid separation sand settling module of the present invention, with image 3It shows that the specific structure of the gas-liquid separation and sand settling module in this embodiment consists of an upper joint 1, an exhaust valve 2, an upper outer pipe 3, a gas collection chamber 13, a central pipe 5, a primary foam breaking body 4, and a secondary breaking body. Bubble body 6, middle collar 8, lower outer tube 18, spiral blade 9, lower joint 12, wherein the upper end of upper outer tube 3 is connected with one end of upper joint 1, the other end of upper outer tube 3 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com