Preparation method of amino inhibited polyamide hot melt adhesive

A polyamide hot-melt adhesive and amine-based technology, applied in the direction of adhesives, etc., to achieve the effect of high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

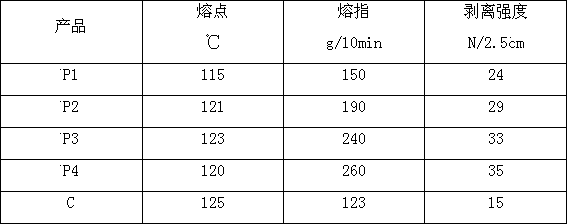

Examples

Embodiment 1

[0016] Add 0.85 mol of sebacic acid, 0.87 mol of decane diamine, 0.45 mol of nylon 66 salt, 3.5 mol of caprolactam, 0.039 mol of hexadecylamine, and 1.72 g of phosphoric acid into the numerically controlled autoclave, constant pressure 1.65Mpa, constant pressure temperature 215℃ , After constant pressure reaction for 0.75h, release the pressure, the time to release to normal pressure is 1.1h, then pass N 2 Atmospheric pressure reaction for 0.75h and discharge to obtain product P1.

[0017]

Embodiment 2

[0019] Add 0.85 mol of sebacic acid, 0.952 mol of decane diamine, 0.65 mol of nylon 66 salt, 4.3 mol of undecalactam, 0.098 mol of dodecylamine, 3.44 g of tungstomolybdic acid, and constant pressure of 1.7Mpa into the numerically controlled autoclave. Constant pressure temperature 220℃, constant pressure reaction for 0.9h, then release pressure, release to normal pressure for 1.2h, then pass N 2 Atmospheric reaction for 0.8h and discharge to obtain product P2.

[0020]

Embodiment 3

[0022] Add 0.85 mol of sebacic acid, 0.89 mol of decanediamine, 0.5 mol of nylon 66 salt, 3.7 mol of caprolactam, 0.05 mol of octadecylamine, 1.94 g of hydrochloric acid, constant pressure 1.6Mpa, constant pressure temperature 200°C into the numerically controlled autoclave , After the constant pressure reaction for 0.5h, release the pressure, the time to release to normal pressure is 1.0h, then pass N 2 Atmospheric reaction for 0.5h and discharge to obtain product P3.

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com