Automatic product extracting jig

An automatic and jig technology, applied in the field of injection molding equipment, can solve the problems of small size, bumps and crushes, and relatively high dimensional accuracy requirements, and achieve the effects of automatic control, reduction of product costs, and avoidance of bumps and falls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

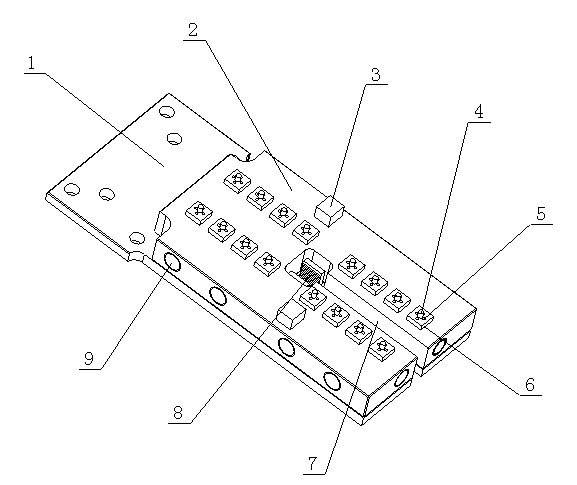

[0023] as attached figure 1 As shown, a product automatic suction fixture includes an air circuit board 2, the upper end surface of the air circuit board 2 is provided with a suction and blowing device, and the air circuit board 2 is provided with an air circuit 9, and the air circuit 9 and the suction and blowing device connected. The air circuit board 2 is provided with an opening 7, the opening 7 extends to the center of the air circuit board 2, and the width of the opening at the center is greater than the width of the opening at the edge.

[0024] The invention is specially matched with the manipulator in the injection molding machine. It can be seen from this that the manipulator is fixedly connected to the lower end surface of the air circuit board 2, and the manipulator clip 8 on the manipulator is located in the opening 7 and is in the center of the air circuit board 2 Location.

[0025] The present invention is combined with vacuum fan, electromagnetic valve, vacu...

Embodiment 2

[0030] The rest is the same as that of Embodiment 1, the difference is that the suction and blowing device includes several installation seats 6 symmetrically installed on the air circuit board 2, and the center position of the end surface of the installation seats 6 is provided with a top post 4, Suction and blowing holes 5 are evenly distributed around, and the suction and blowing holes 5 communicate with the air passage 9 .

[0031] In this embodiment, the number of mounting seats 6 is set according to actual needs. Generally, there are 16 mounting seats 6 installed symmetrically on the upper end surface of the air circuit board 2 . Suction and blow holes 5 are uniformly arranged around the top column 4 .

[0032] The function of the top column is to prevent the product from directly covering the suction and blowing holes 5 when the product is sucked, causing the suction and blowing holes 5 to fail to inhale, or to inhale poorly.

Embodiment 3

[0034] The rest is the same as the embodiment 2, except that several fine positioning blocks 3 are provided on the edge of the air circuit board 2 .

[0035] The number and installation positions of the fine positioning blocks 3 are determined according to the actual needs of the product. In this embodiment, there are two fine positioning blocks 3 , which are respectively installed relative to the center of the air circuit board 2 . The function of the fine positioning block 3 is to accurately locate the position of the product, so that it can be accurately delivered to the predetermined position when it is delivered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com