Pneumatic conveying type suspender profiling ripener spraying machine for cotton fields

An air-fed and ripening agent technology, which is applied in the field of air-fed boom profiling ripening agent sprayer in cotton fields, can solve the problems of uneven internal and external adhesion, high residual amount of liquid medicine, and decline in cotton quality, and achieve a solution The effect of high liquid residue, enhanced penetration, and reduced operating loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

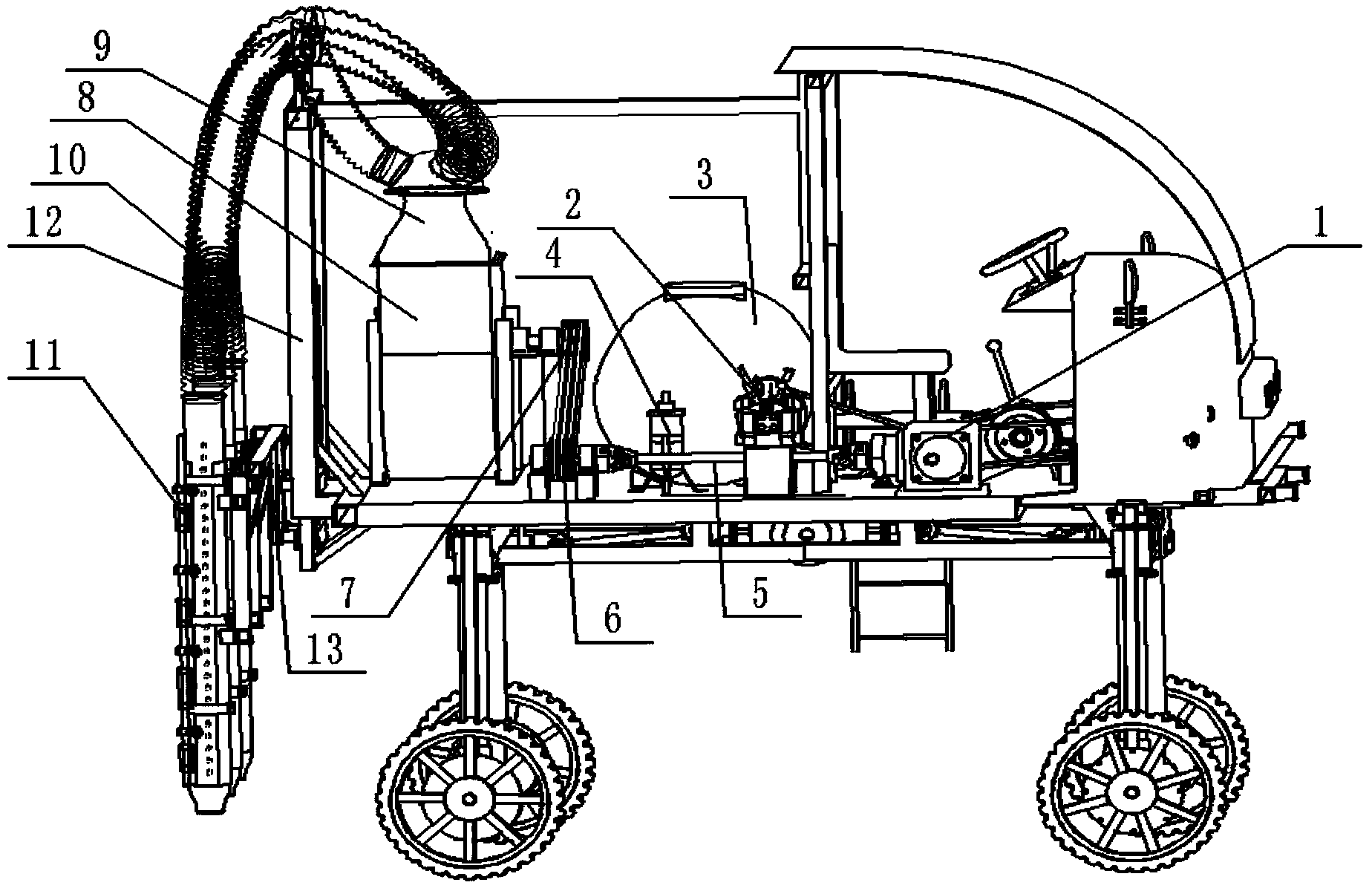

[0026] The power of the tractor is driven by the belt between the output pulley and the input pulley of the commutator, and reaches the commutator (1). Part of the power is transmitted to the diaphragm pump (2) through the belt drive between the pulley on the shaft and the diaphragm pump pulley, driving the diaphragm pump (2) to rotate at high speed to provide the required power for the spray system. Another part of the power output by the output shaft at the rear end of the commutator is transmitted to the centrifugal fan pulley Ⅰ (6) through the transmission shaft (5), and the power passes between the centrifugal fan pulley Ⅰ (6) and the centrifugal fan pulley Ⅱ (7). The belt transmission is transmitted to the centrifugal fan (8), which drives the centrifugal fan (8) to rotate at high speed to provide the required power for the air delivery system.

[0027]Under the action of the high-speed rotating diaphragm pump, the liquid medicine flows out from the liquid medicine tank ...

Embodiment 2

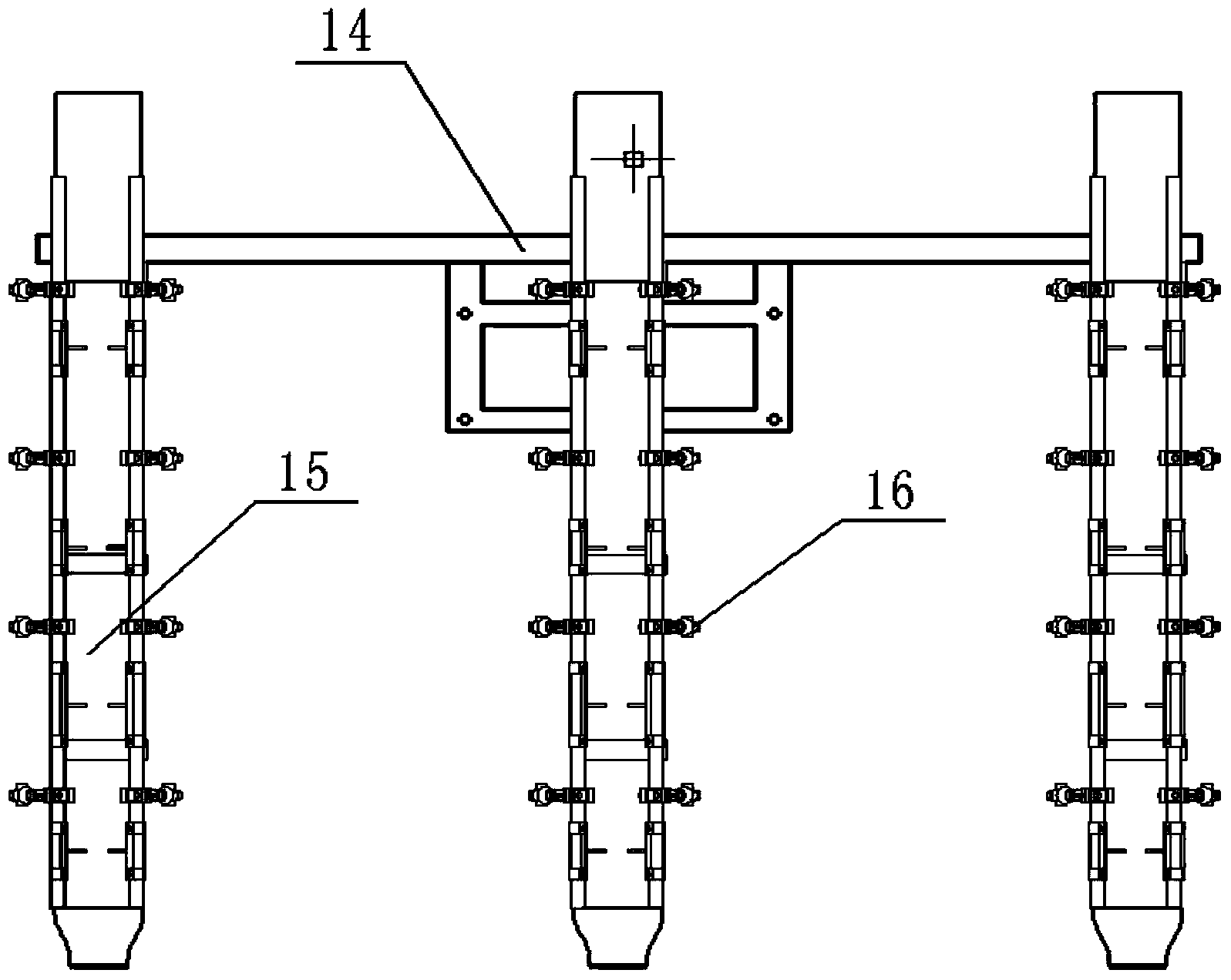

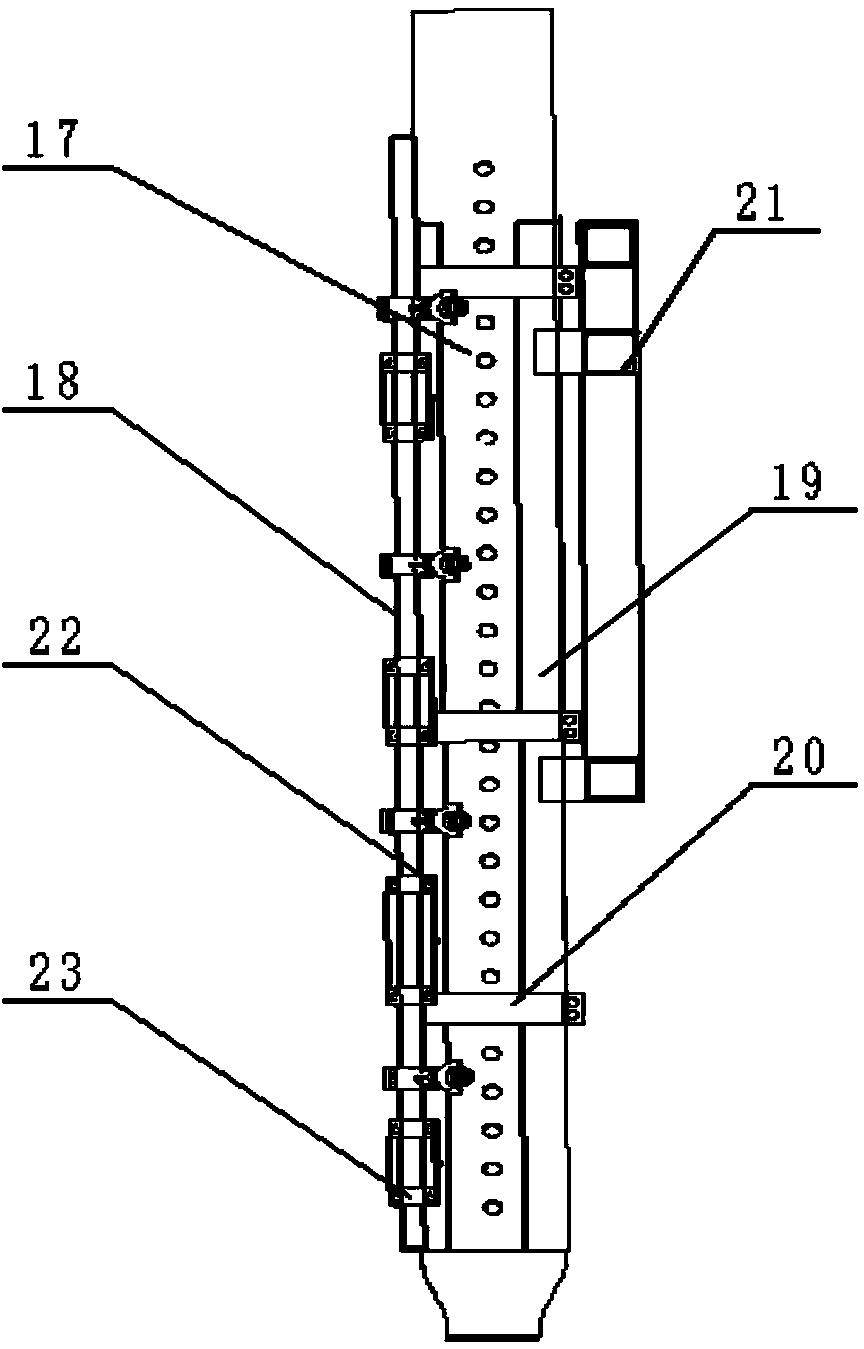

[0031] The present invention needs to be used in conjunction with a high clearance tractor suitable for cotton plant protection operations in the late stage, and the power transmission device, liquid medicine spray system, air delivery system, and hydraulic lifting mechanism are reasonably arranged and installed on the tractor. In this example, three boom profiling mechanisms are provided to tightly enclose the front shield (19) and the rear shield (22) on the front and rear sides of the perforated air duct (17) (with the forward direction of the tractor as the front). Clamp (20) fixes the three, wherein the clamp of the porous air duct is installed between the front and rear shields, and the air outlet is towards both sides. Connect the front shield to the boom connecting frame (14) with connecting square steel (21), and the boom connecting frame (14) is closely connected with the lifting connecting frame (13). A vertical drug rod (18) is respectively installed on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com