Coal mine ventilation air methane back-heating catalytic oxidation device with combined type oxidation bed

An oxidation device and catalytic oxidation technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of poor operation stability, high light-off temperature, low oxidation efficiency, etc., achieve enhanced flow capacity, reduce ignition The effect of increasing the combustion temperature and increasing the oxidation rate of methane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

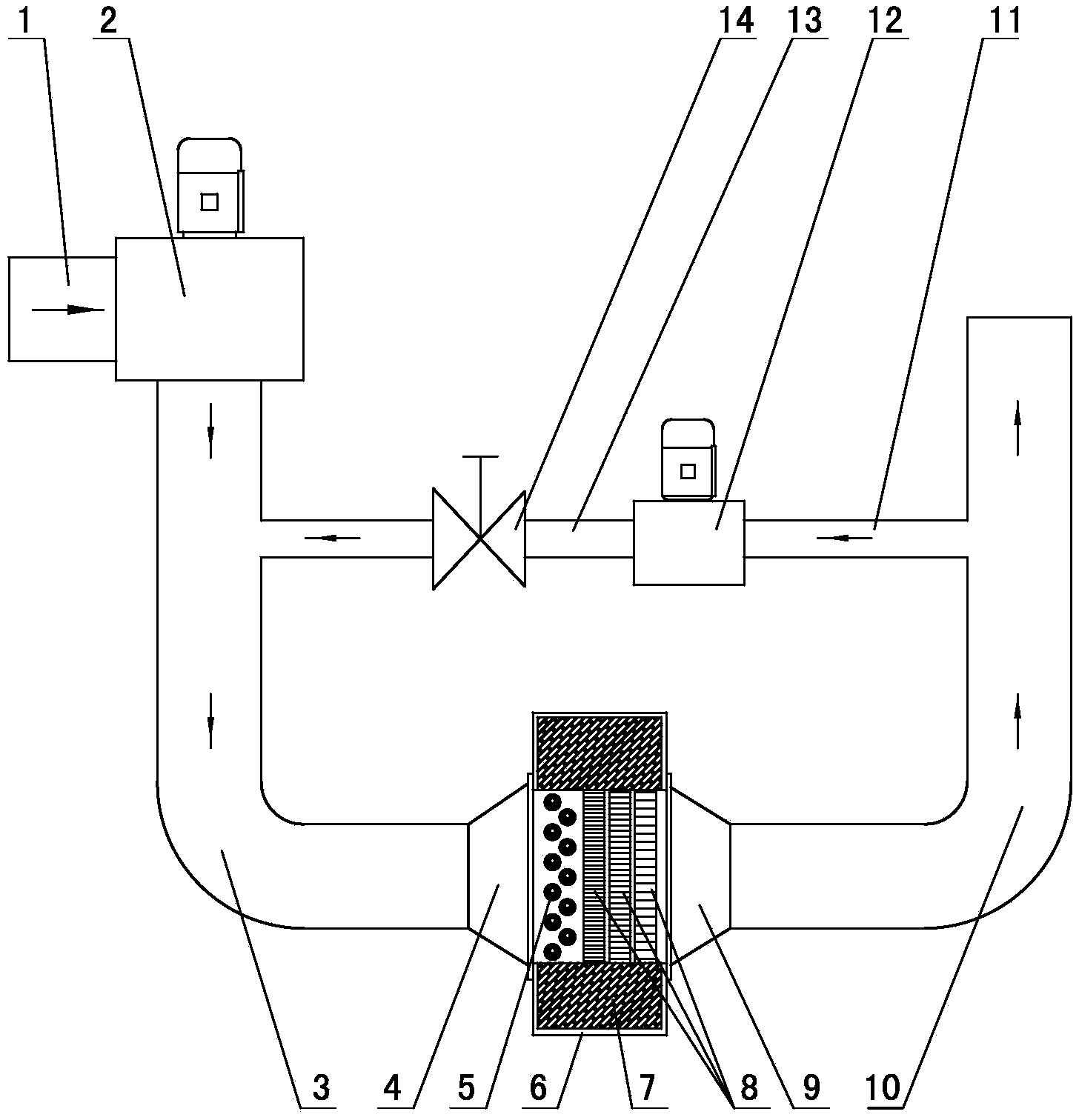

[0013] The present invention will be further described below in conjunction with the accompanying drawings. exist figure 1 In the shown embodiment: the output end of the exhaust air delivery pipe 1 is connected to the inlet of the reaction chamber through the blower 2, the exhaust air inlet pipe 3, and the expansion pipe 4 in sequence; the exhaust air exhaust system includes a contraction pipe 9 and an exhaust air outlet pipe 10, wherein one end of the shrink tube 9 communicates with the outlet of the reaction chamber, and the other end communicates with the atmosphere through the exhaust air outlet pipe 10; Heat connection pipe 13, wherein one end of the heat recovery inlet pipe 11 is connected with the exhaust air outlet pipe 10, and the other end is connected with the exhaust air inlet pipe 3 through the heat recovery fan 12 and the heat recovery connection pipe 13 in turn; the reaction chamber is equipped with The reaction chamber casing 6 of the insulation layer 7 is sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com