A special vacuum drum filter for treating ultrafiltration tank bottoms and a treatment method for ultrafiltration tank bottoms

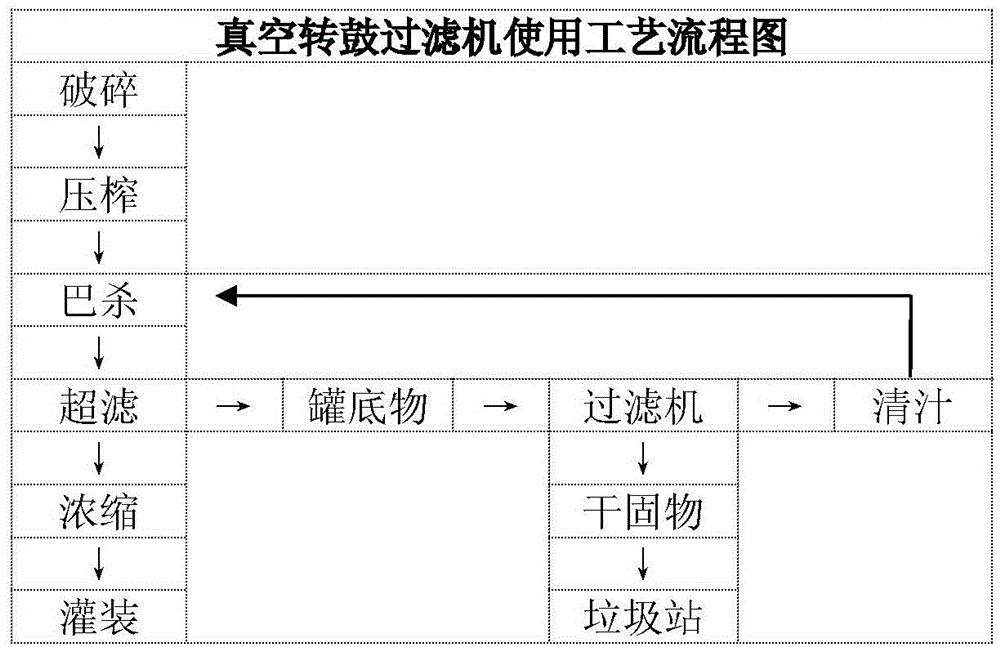

A technology of vacuum drum and treatment method, applied in the direction of moving filter element filter, filtration separation, separation method, etc., can solve the problems of occupying ultrafiltration cleaning, production time, increasing the difficulty and cost of sewage treatment, and insufficient juice extraction. , to achieve good solid-liquid separation effect, reduce sewage treatment costs, and shorten cleaning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

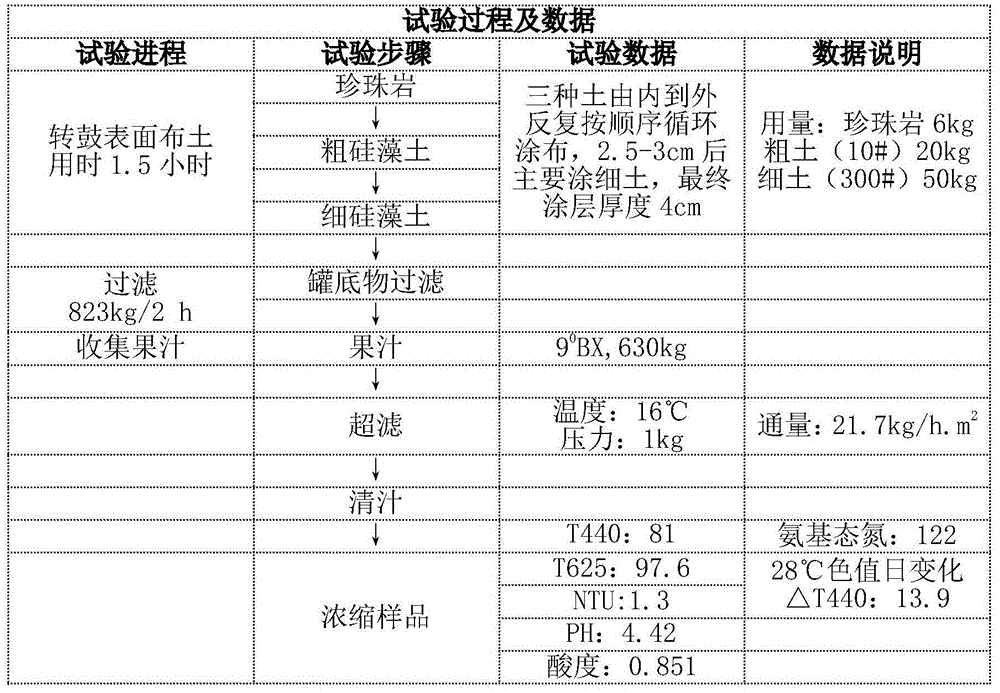

[0026] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

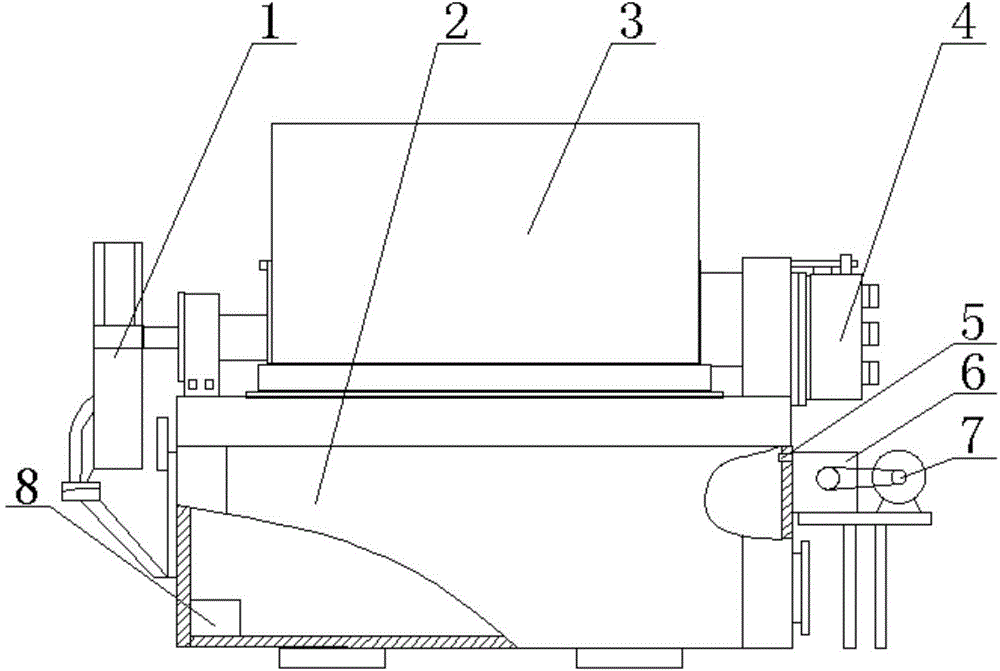

[0027] A special vacuum drum filter for processing ultrafiltration tank bottoms, including a drum driving device 1, a filter tank 2, a drum 3, a distribution head 4, and a stirring device. The drum is horizontally fixed on the upper surface of the filter tank, and the drum One end is equipped with a drum driving device, which drives the drum main shaft to rotate, and the other end of the drum is installed with a distribution head, which is equipped with three pipe connection joints, respectively connected to the filtrate outlet port, compressed air inlet port, vacuum pump port, A stirring device (blocked on the way, not shown) is also installed at the bottom of the filter tank.

[0028] In addition to the devices and structures described ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com