Eagle claw type automatic Chinese chestnut opening machine

A kind of opening machine, eagle claw type technology, applied in the field of eagle claw type chestnut automatic opening machine, can solve the problems of low cutting speed, insufficient cutting, troublesome control, etc., and achieve the effect of improving conveying efficiency and preventing slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] For ease of description, below in conjunction with accompanying drawing, the eagle claw type chestnut automatic opening machine of the present invention is described in detail.

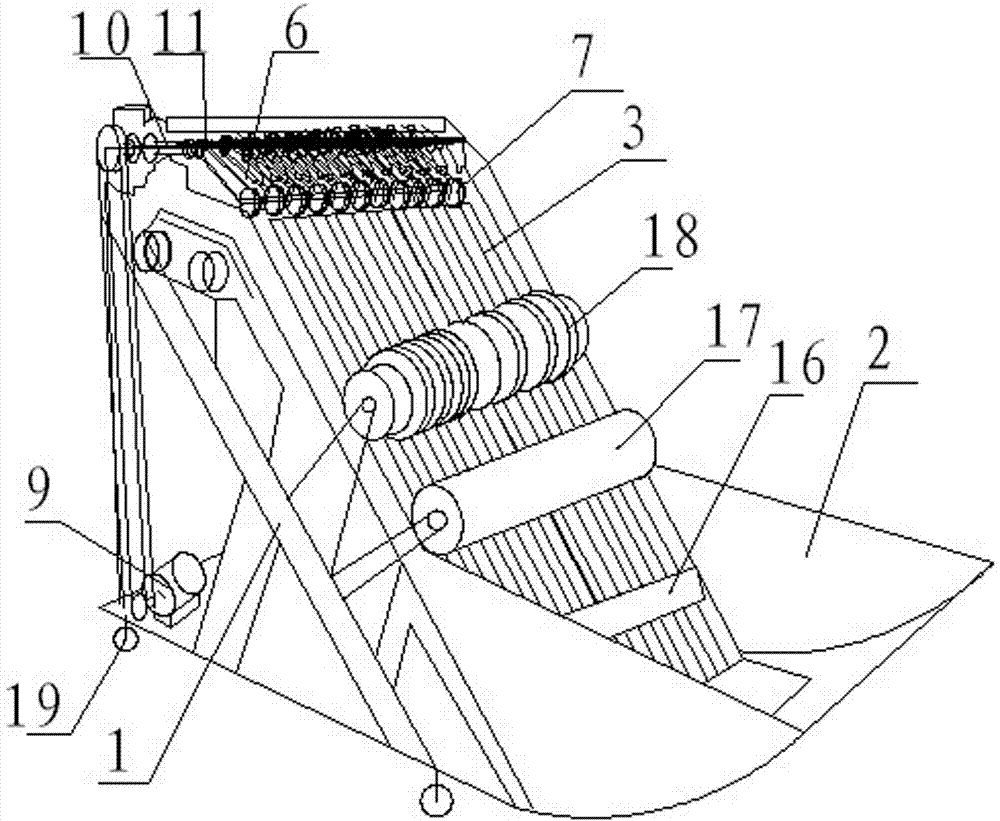

[0038] Such as Figure 1 to Figure 3 Shown in , a kind of eagle claw type chestnut automatic opening machine comprises frame 1, and described frame 1 is provided with feeding system, cutting system and transmission system.

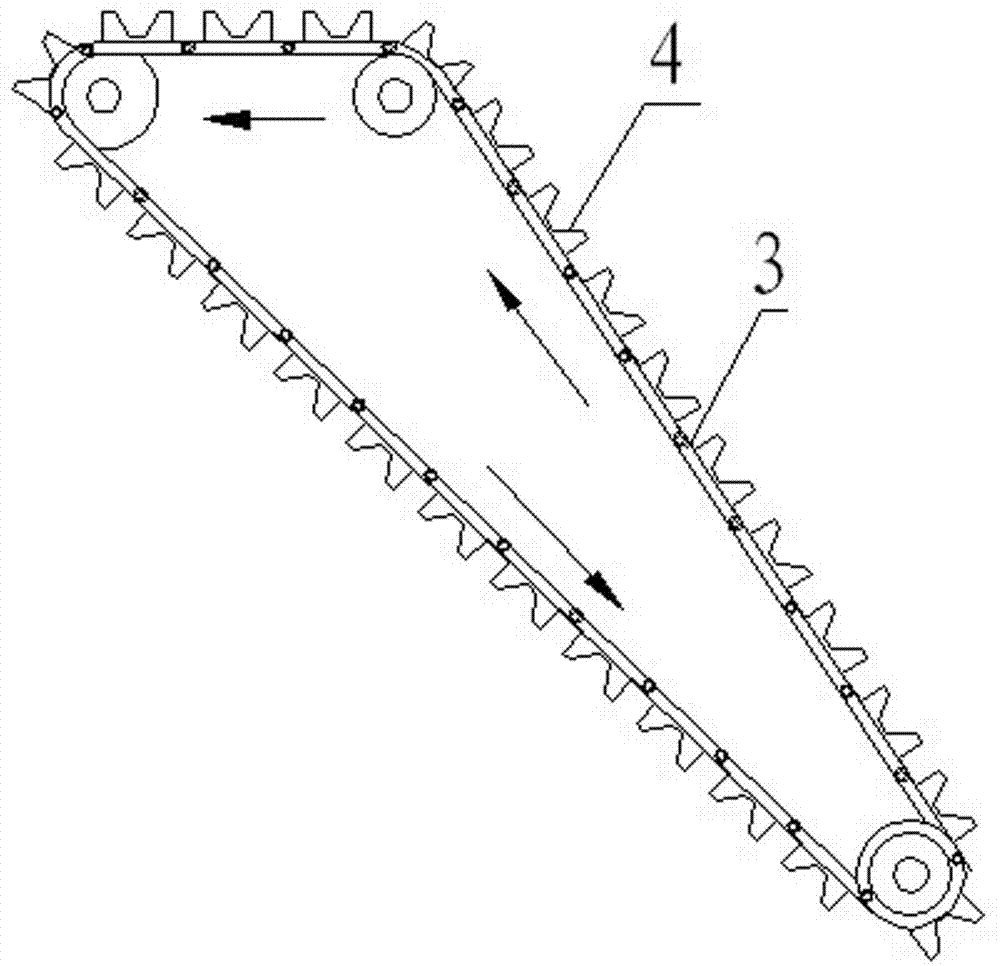

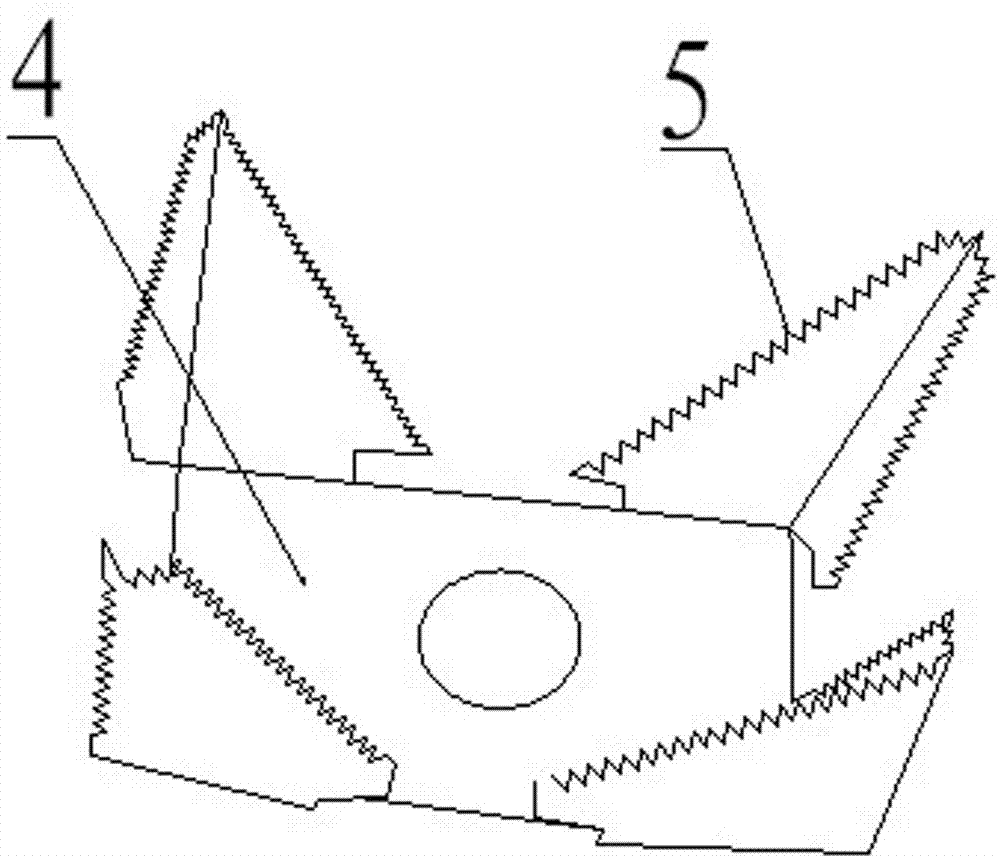

[0039] The feeding system includes a feed box 2 and a conveyor belt 3, the conveyor belt 3 is formed by connecting several chain belts through shafts, and the conveyor belt 3 is formed into a triangle The rotary conveyor belt of the shape, the chestnut conveyor belt 3 from the feeding box 2 to the chestnut cutting is called the chestnut conveyor section, and forms an angle of 45° with the horizontal plane, and the section from the chestnut cutting to the chestnut collection is called the chestnut cutting section, and Set parallel to the horizontal plane.

[0040] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com