Strengthened module assembly shell and assembly method of strengthened module assembly shell

An assembly method and component technology, applied in the direction of sealed casings, etc., can solve the problems of highly targeted use range, different electronic devices, and inapplicable scale, etc., and achieve the effects of wide use range, good compression resistance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

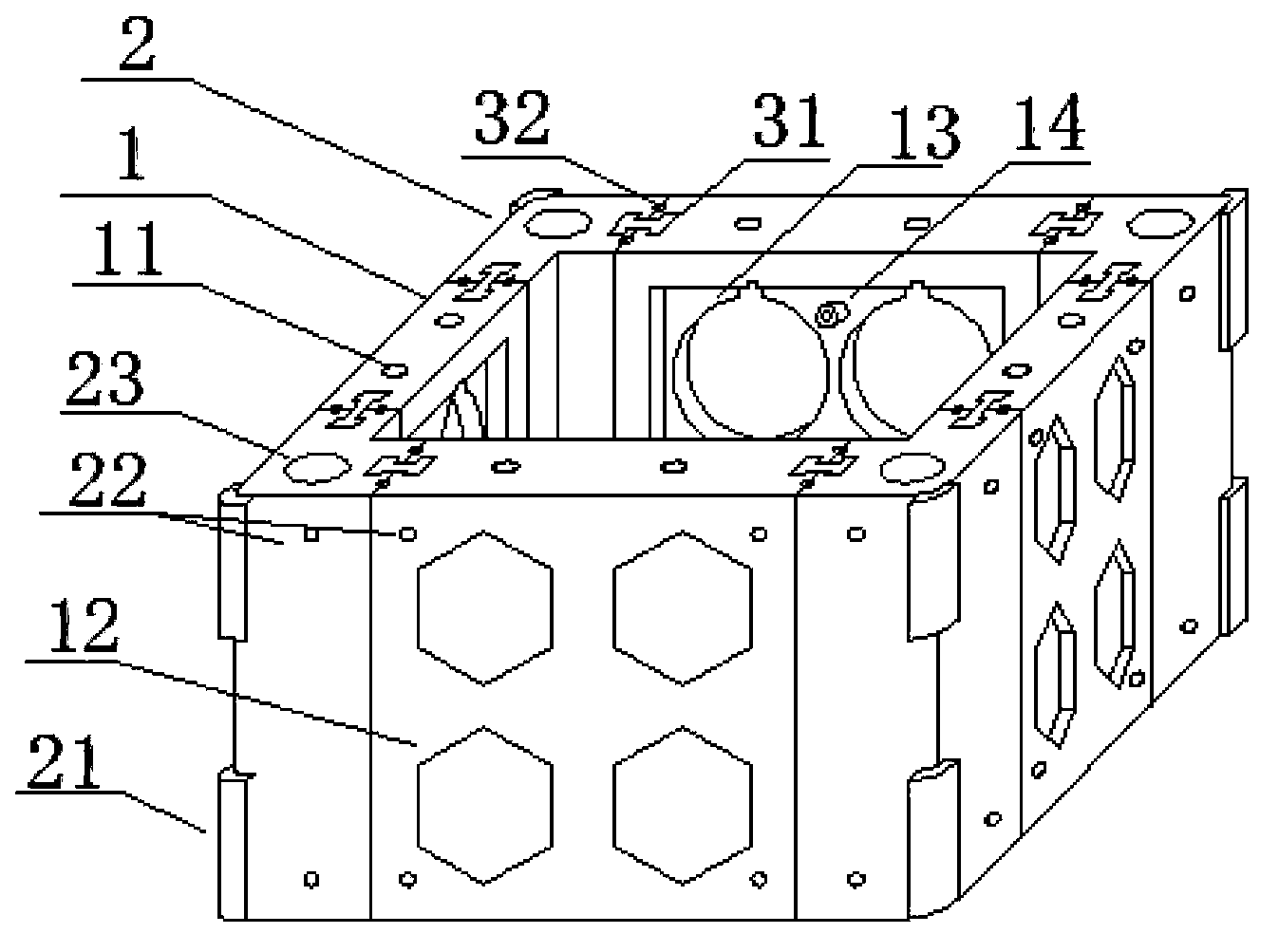

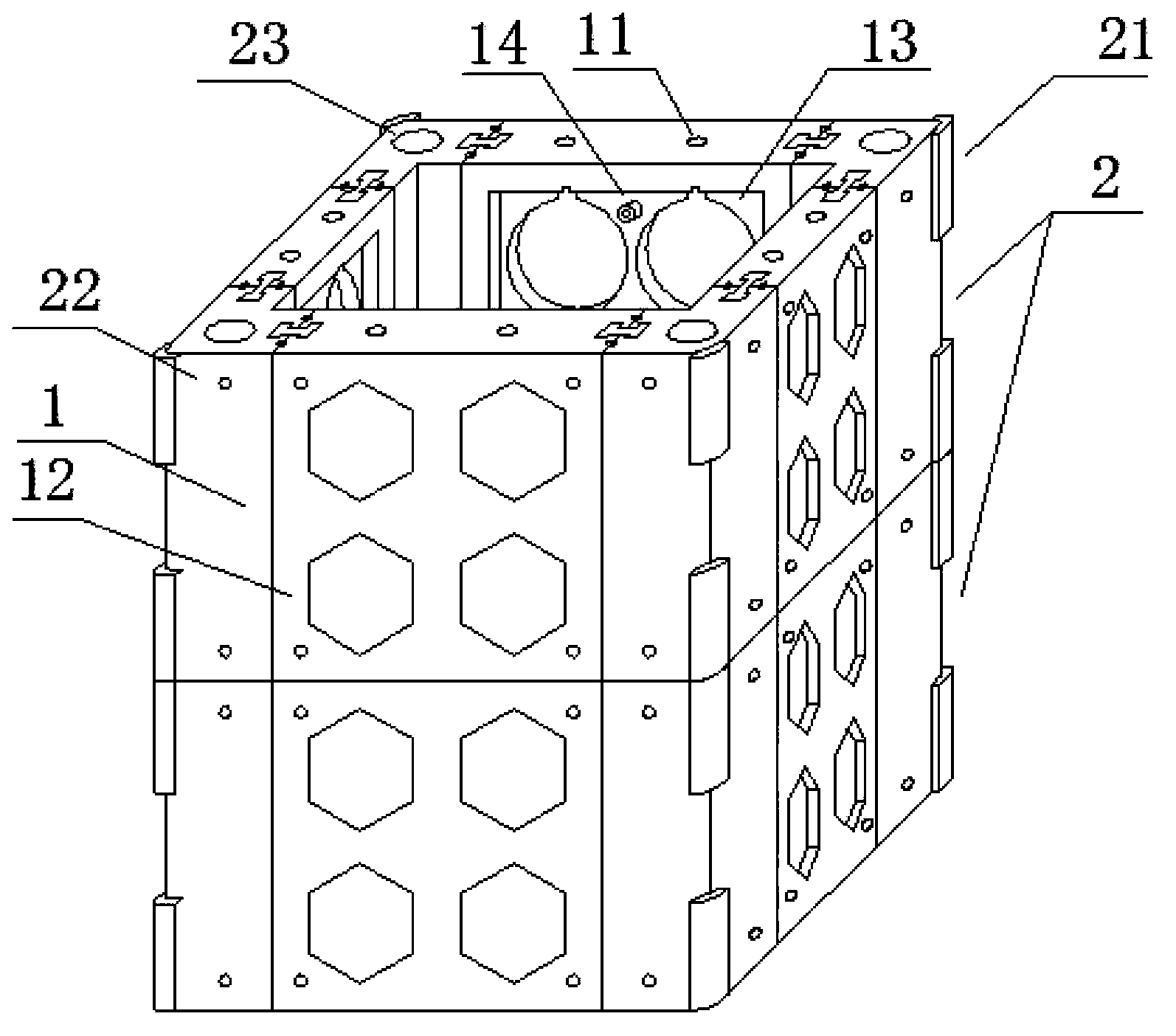

[0041] Such as image 3 As shown, combine the modules and connectors into a cuboid, first select eight rectangular modules 1 and eight L-shaped modules 2, group four L-shaped modules 2 and four rectangular Module 2 and rectangular module 1 are placed at intervals to form a shell outer wall with a square cross section, and then align the L-shaped module 2 and the T-shaped slot of the rectangular module 1 to form an I-shaped slot, and insert the I-shaped card Components to realize the preliminary connection of the modules, and a ring-shaped component can be obtained. In order to strengthen the fastness of the ring component, liquid thermoplastic glue is poured into each glue hole on the ring component, and the ring component is assembled after the liquid gel is cooled and solidified.

[0042] The two side surfaces of the L-shaped module 2 and the rectangular module 1 used in this program are respectively provided with two connecting through grooves 31, and the I-shaped clamps c...

Embodiment approach 2

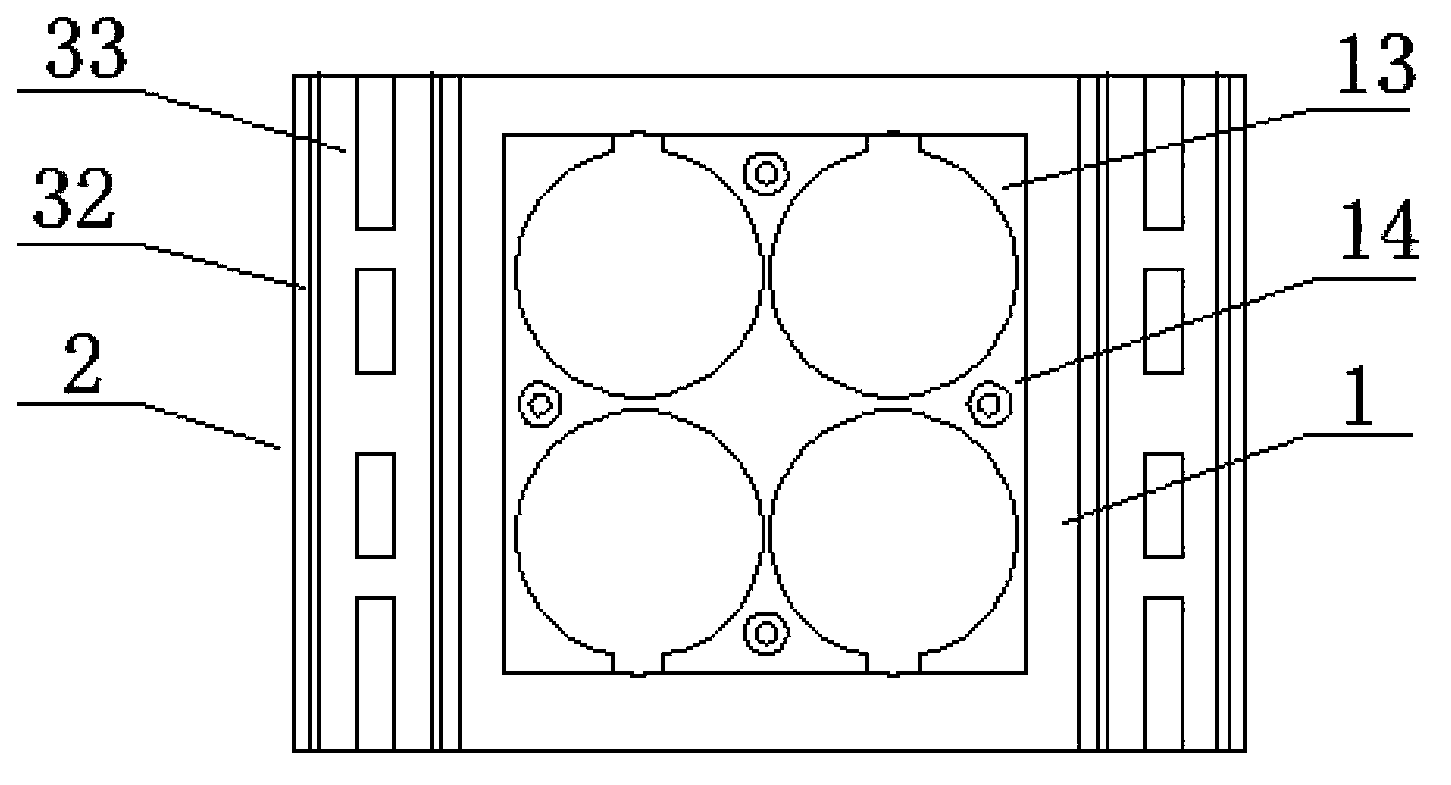

[0046] Such as Figure 4 As shown, the L-shaped module 2 and the rectangular module 1 are assembled into a prism with a concave cross section. First, eight L-shaped modules 2 and three rectangular modules 1 are selected. The same side surfaces of the L-shaped module and the rectangular module are provided with A connecting slot 33, the connecting slot 33 is a dovetail slot, the length of the dovetail slot is equal to the height of the rectangular module, the L-shaped module 2 and the rectangular module 1 are placed on the outer wall of the housing according to the concave structure, and the housing The recessed structure of the external wall is formed by reversely or symmetrically docking four L-shaped modules 2. Then, the funnel-shaped through-slot formed by butting the dovetail-shaped through-slots of different modules is inserted into the funnel-shaped clamp, and the shell is The glue filling hole on the outer wall is filled with thermoplastic colloid. While waiting for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com