Ejector pin device, lower electrode assembly, and assembly and disassembly methods of lower electrode assembly

An electrode assembly and thimble technology, which is applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems that the thimble affects the installation and debugging of equipment, the unreasonable position of the thimble, and the touch, so as to avoid the installation of semiconductor processing equipment. and commissioning effects, avoiding the effects of installation and commissioning, reducing the effects of deformation or breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

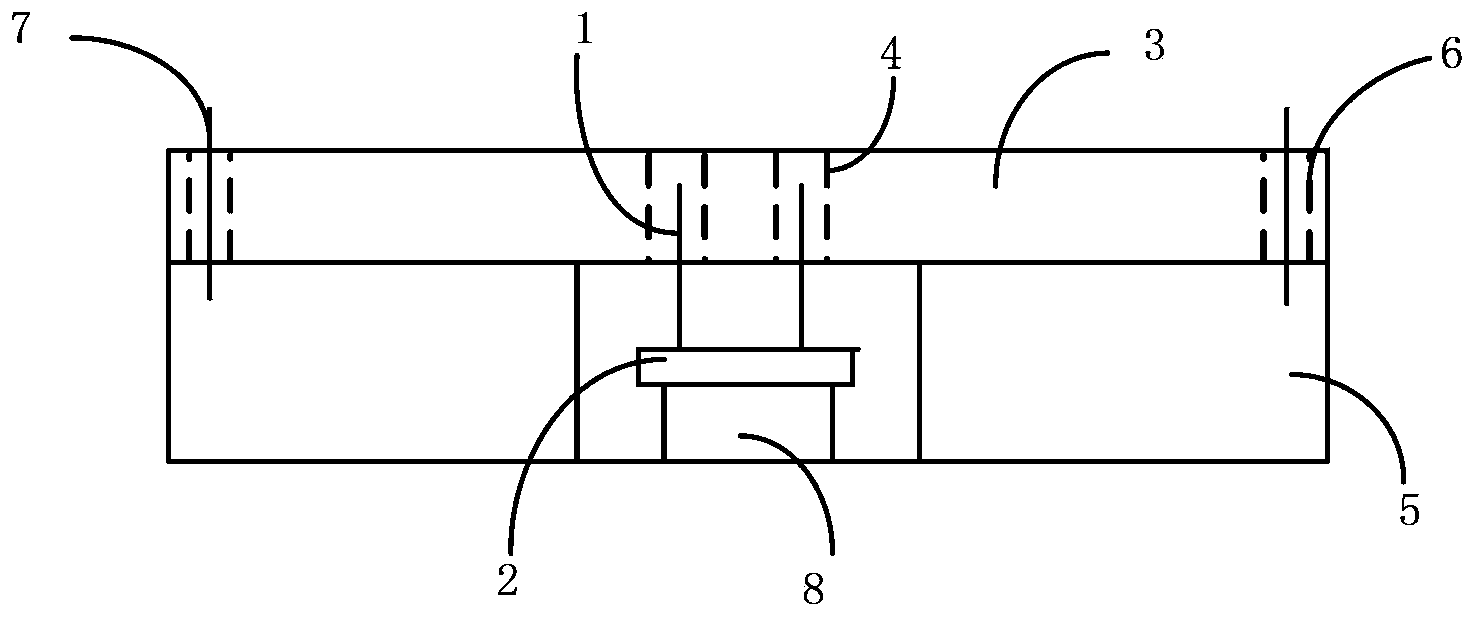

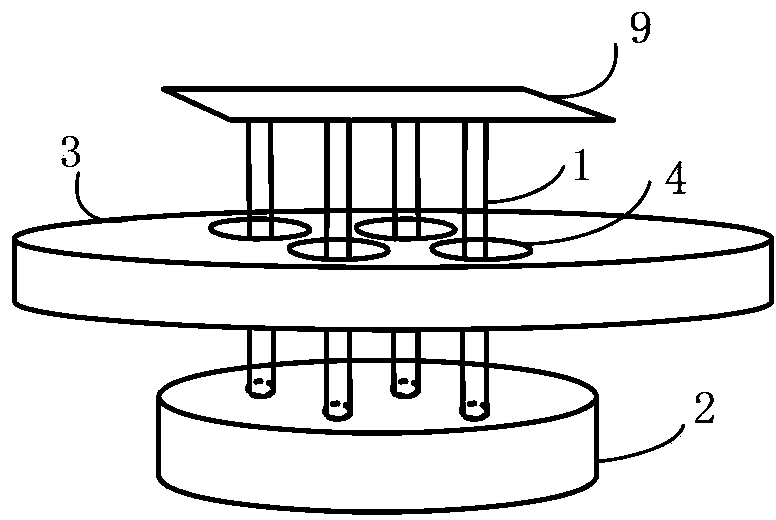

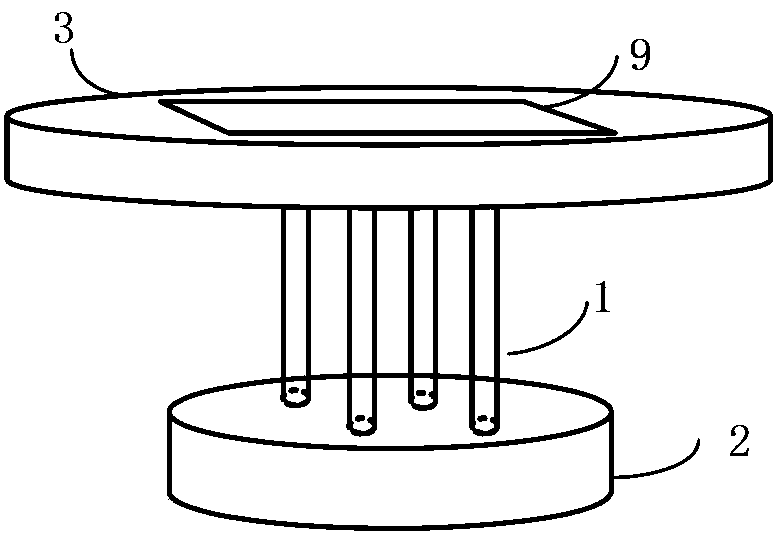

[0046] In order for those skilled in the art to better understand the technical solution of the present invention, the lower electrode assembly, ejector pin device, lower electrode assembly installation method and lower electrode assembly disassembly method provided by the embodiments of the present invention are described in detail below with reference to the accompanying drawings.

[0047] Embodiment 1 of the present invention provides a lower electrode assembly. see image 3 The lower electrode assembly provided in Embodiment 1 of the present invention includes a thimble device and an electrostatic chuck 35 used in conjunction with the thimble device.

[0048] Wherein, the thimble device in the lower electrode assembly is used in cooperation with the electrostatic chuck 35 to complete the seating or unseating process of workpieces such as wafers in the process chamber. Generally, the number of thimbles 31 on the thimble base 32 may be but not limited to three or four, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com