Overhead pipe wall thickness corrosion scanning and detecting system

An overhead pipeline and detection system technology, which is applied in the direction of electric/magnetic thickness measurement, electromagnetic measurement device, material magnetic variable, etc., can solve the problems of high operating level requirements for detection personnel, unsuitable for large-scale promotion and application, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

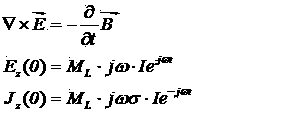

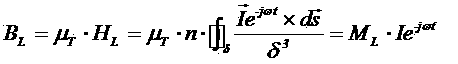

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

[0029] like figure 1 as shown, figure 1 It is a structural diagram of the overhead pipeline wall thickness corrosion scanning detection system of the present invention. The overhead pipeline wall thickness corrosion scanning detection system consists of a transmitting clamp 1 , a receiving clamp 2 , a distance controller 3 and an operation box 4 . The distance controller 3 is the connection between the transmitting clamp 1 and the receiving clamp 2, and controls the distance between the transmitting clamp 1 and the receiving clamp 2. The operation box 4 is connected to the transmitting clamp 1 and the receiving clamp 2, and transmits a current signal to the transmitting clamp 1, collects the induced current signal generated by the receiving cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com