Method and special check valve for preventing contraflow of oil circuit of transformer

A technology of reverse flow and transformer oil, applied in the field of transformers, can solve problems such as unfavorable transformer heat dissipation, reverse flow of transformer oil, short circuit of oil circuit, etc., to completely prevent reverse oil flow, increase oil flow speed, circulation and cut-off reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

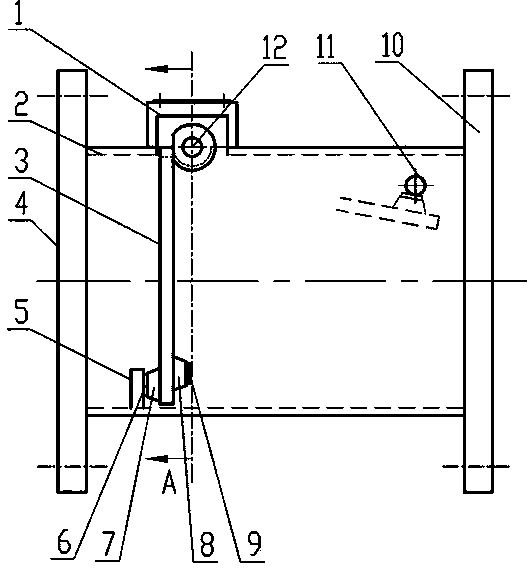

[0034] Embodiment one, with reference to the attached Figure 9 , when in use, the axes of flange one, valve box and flange two are placed at an inclination of 35° from the vertical line, and when installed, the transformer radiator manifold is located on the upper left of flange one. The flow direction of the transformer oil is downward. Under normal conditions, the baffle is naturally drooped by gravity, and the baffle stops at the second position of the limit plate, and the forward transformer oil flow passes smoothly; when the reverse transformer oil flow occurs, it is affected by the transformer When the oil flows, the baffle is impacted and returns to the position of the limit plate 2. At this time, the baffle is perpendicular to the axis of the valve box and the flange 2. The valve box is closed and cut off, and the transformer oil circuit is cut off, thereby inhibiting reverse flow. of transformer oil flow.

Embodiment 2

[0035] Embodiment two, referring to the attached Figure 10 , when in use, the axes of flange 1, valve box and flange 2 are placed at an angle of 35° to the vertical line, and when installed, the transformer radiator manifold is located at the upper right of flange 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com