Automobile magneto-rheological absorber based on multistage circumferential flow mode

A magnetorheological shock absorber, flow mode technology, applied in vibration suppression adjustment, non-rotation vibration suppression and other directions, can solve problems such as structural arrangement restrictions, achieve easy realization of component structure and shape, high magnetic field utilization, coil The effect of a small number of turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

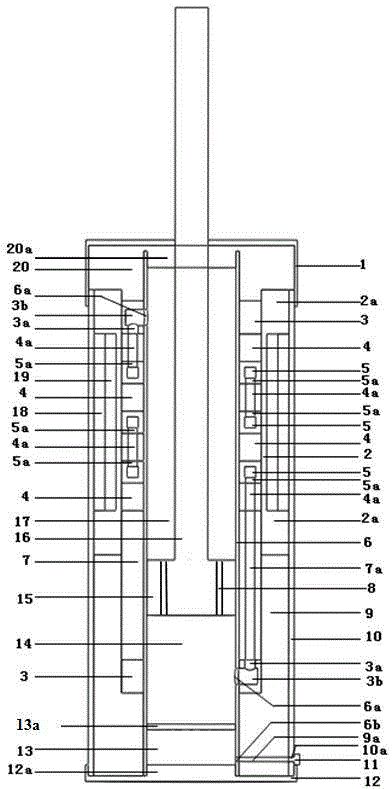

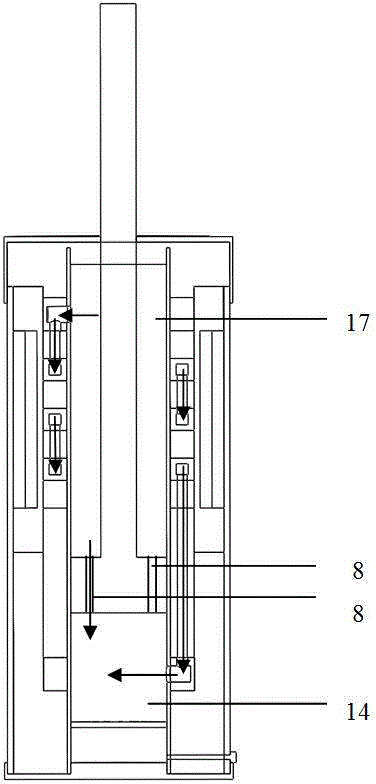

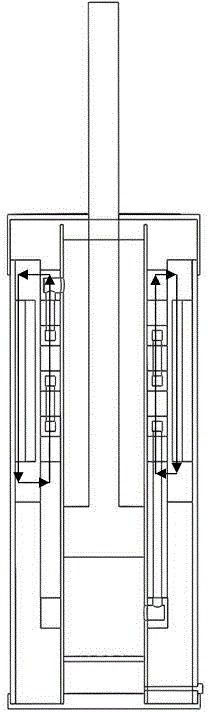

[0019] see figure 1 and figure 2 : The magneto-rheological shock absorber that the present invention relates to is made up of upper outer end cover 1, outer cylinder 2, outer cylinder end magnetic block 2a, circulation block 3, annular block 4 of high magnetic permeability, circumferential channel 5, Inner cylinder 6, support cylinder 7, support block 9, jacket 10, air nozzle 11, lower outer end cover 12, lower seal 12a, diaphragm 13a, piston 15, piston rod 16, magnetic guide cylinder 18, coil 19, upper Positioning cover 20, upper seal and guide 20a etc. are formed. Wherein: the coil 19 is wound on the outer wall of the outer cylinder 2, and the magnetic block 2a at the end of the outer cylinder itself is the main path of the magnetic circuit; The outer wall is co-located by the inner wall of the outer cylinder 2 in the radial direction, and is co-located by the flow cover 3, the support cylinder 7, and the support block 9 in the vertical direction; the inner cylinder 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com