Injection pump, injection system and injection method

A technology of injection system and injection pump, which is applied in pumps, pump control, liquid variable capacity machinery, etc., can solve the problems of poor versatility, achieve the effects of improving versatility, improving injection accuracy, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

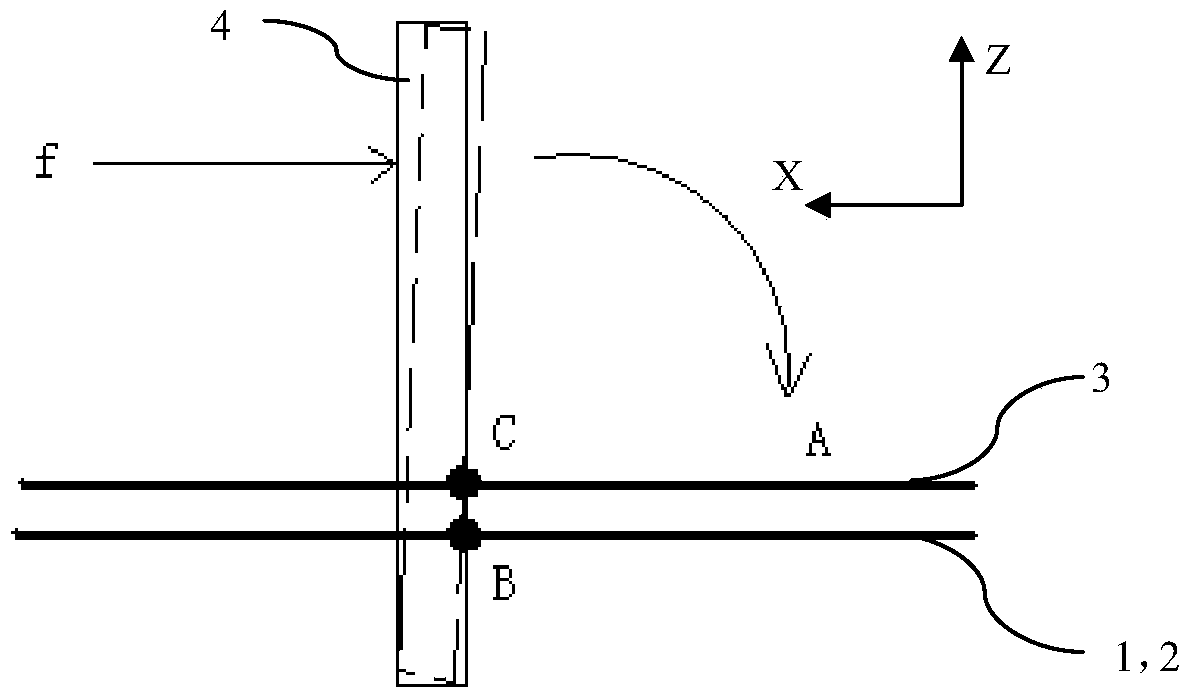

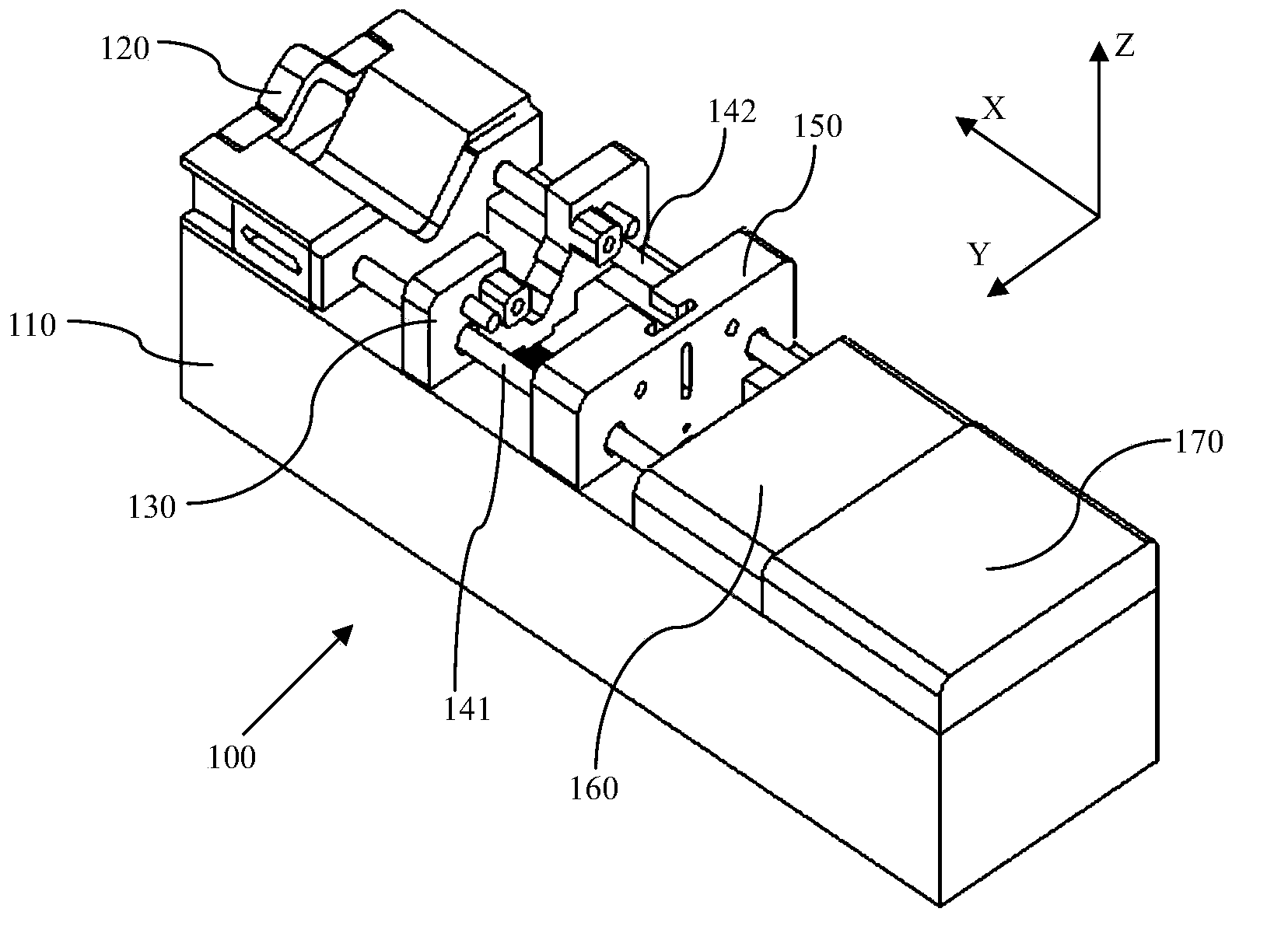

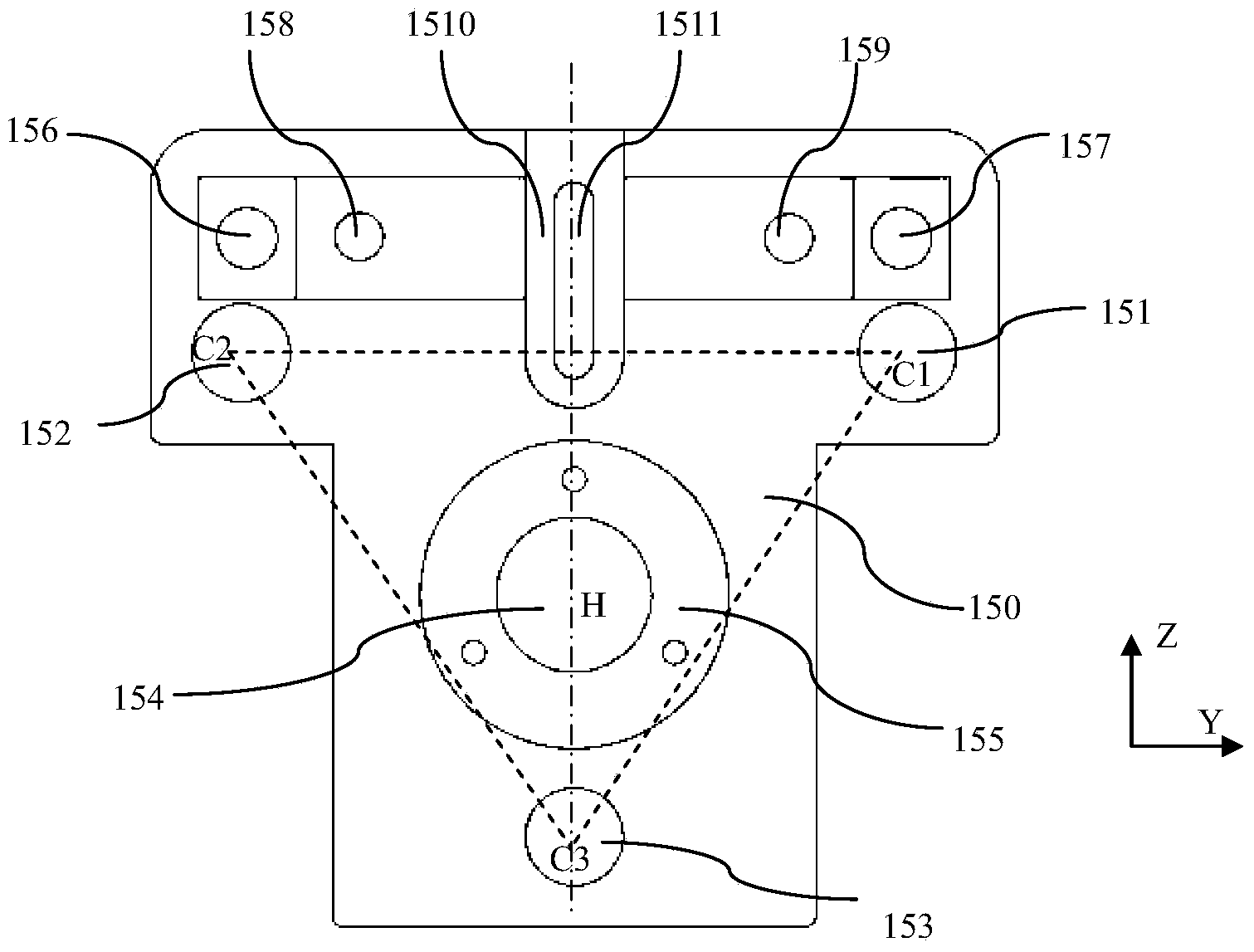

[0045] In the following description, for the sake of clarity, a three-dimensional coordinate system is established, where the X direction refers to the length direction (injection direction) of the syringe pump, the Z direction refers to the height direction (up and down direction) of the syringe pump, and the Y direction refers to the Refers to the width direction (left and right direction) of the syringe pump.

[0046] refer to figure 1 , the syringe pump in the prior art generally uses two guide rails, and the two guide rails (or called guide rods) or push rods 1 and 2 are arranged in parallel in the same plane, and the driving mechanism 4 used to push the syringe handle receives the wire The driving of the rod 3 moves along the X direction, and generally in consideration of reducing the size, the distance between the lead screw 3 and the plane where the two guide rails 1 and 2 are located in the Z direction is not very large. After the syringe (not shown) is clamped on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com