System and method for collecting rotation speed signals of internal combustion engine

A technology of internal combustion engine speed and acquisition system, applied in mechanical equipment, engine control, machine/engine, etc., can solve the problems of high cost, low flexibility, increased cost, etc., to save costs, ensure consistency, and delay signal transmission. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

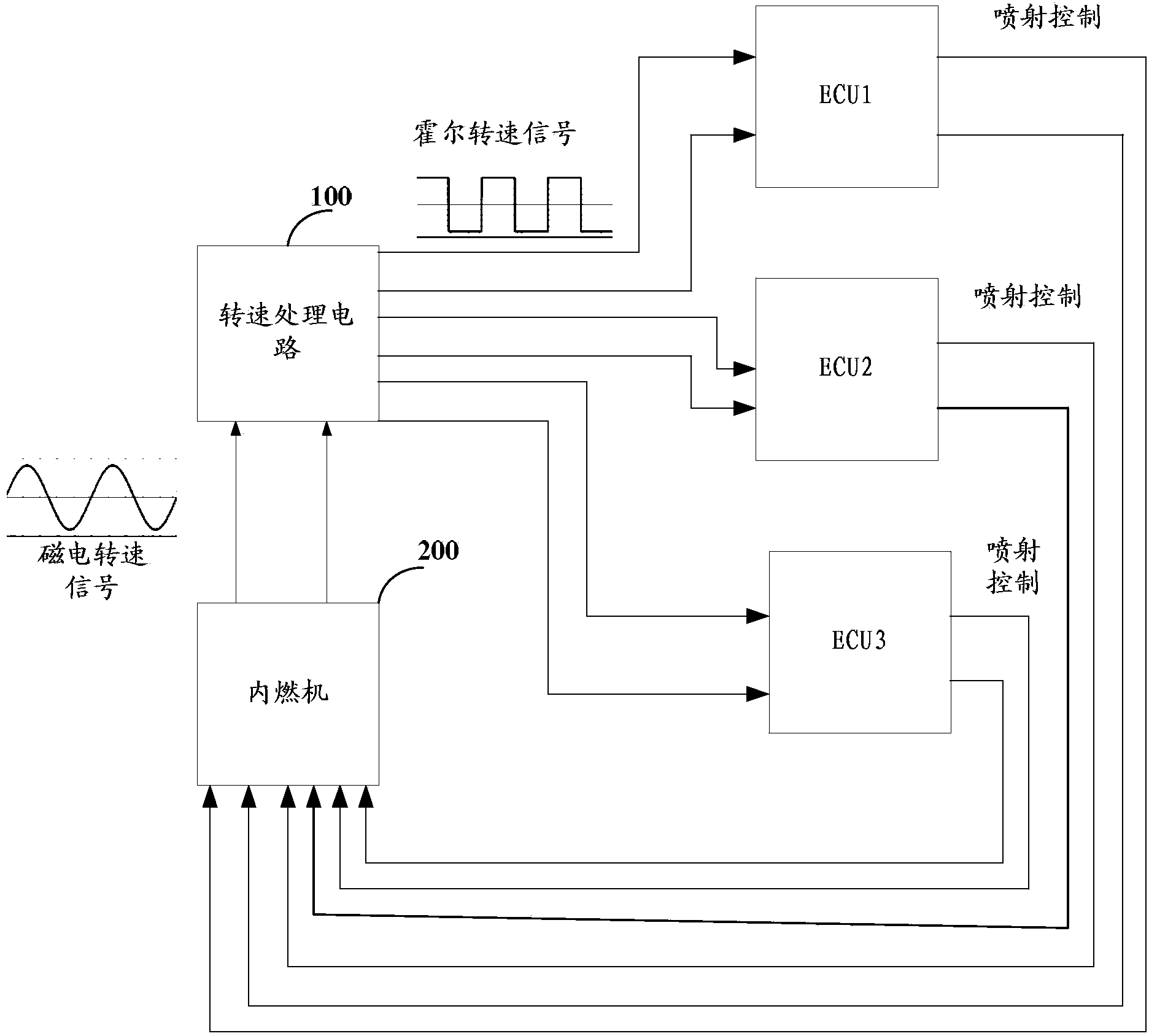

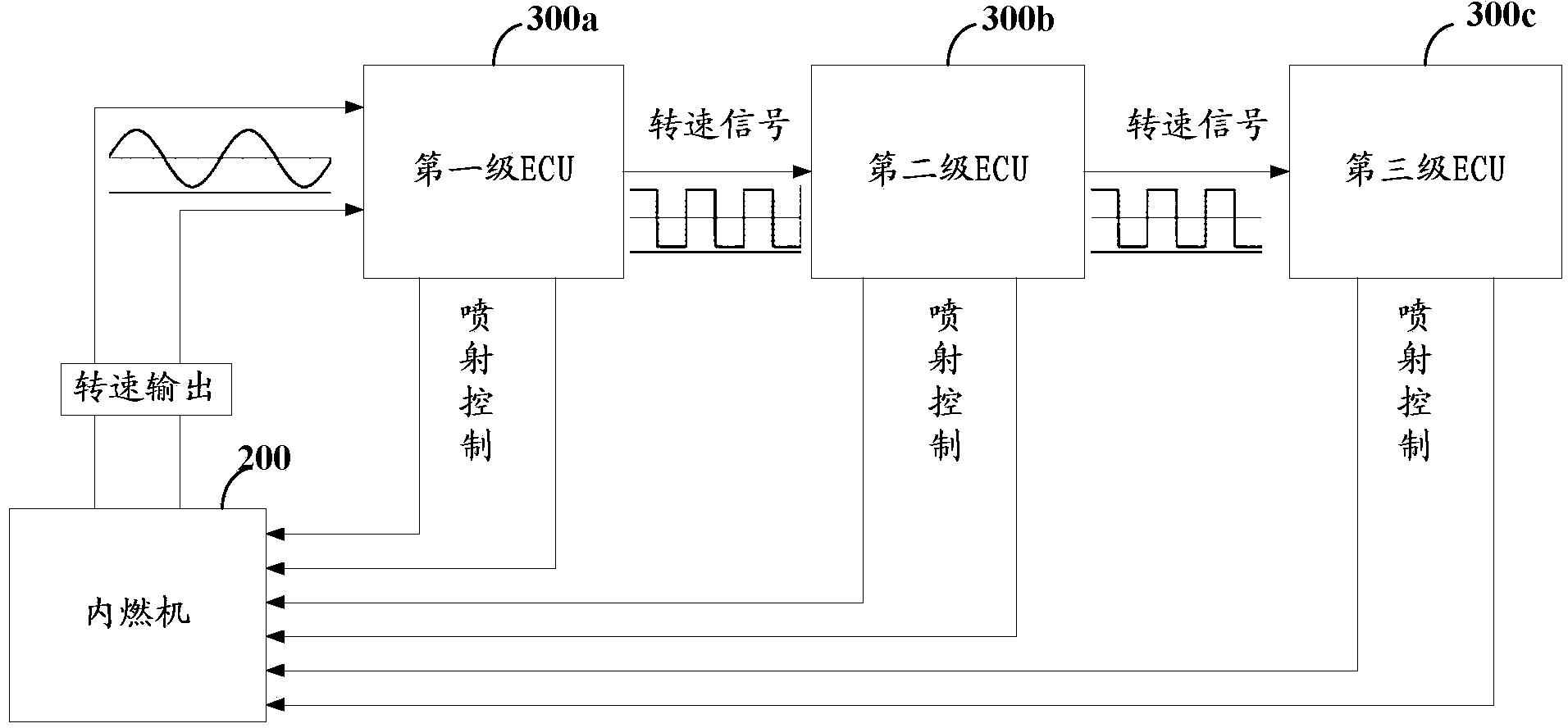

[0049] see figure 2 , which is a schematic diagram of Embodiment 1 of an acquisition system for an internal combustion engine speed signal provided by the present invention.

[0050]The acquisition system for the rotational speed signal of an internal combustion engine provided by this embodiment includes: a plurality of ECUs; in this embodiment, three ECUs are used as an example for introduction, which are a first-level ECU 300a, a second-level ECU 300b, and a third-level ECU 300c;

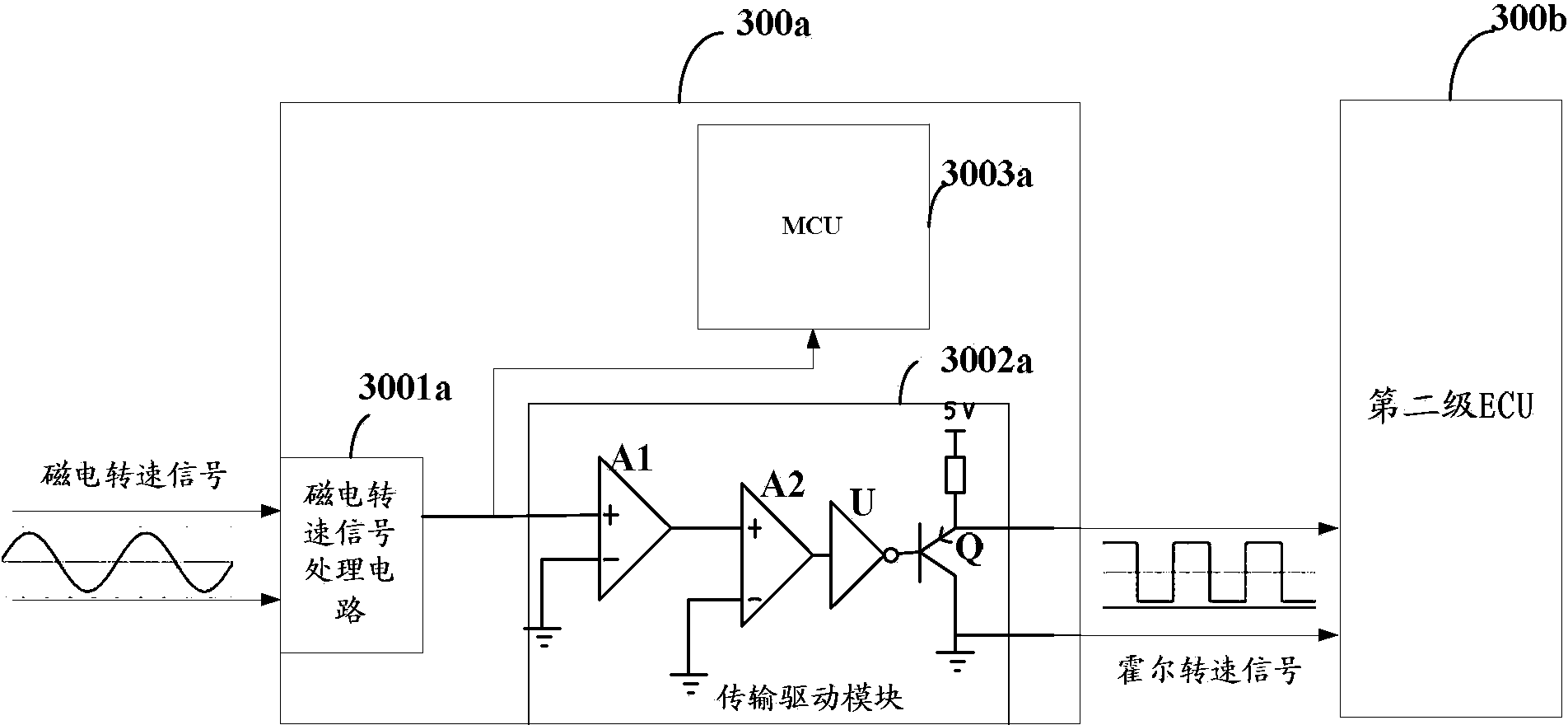

[0051] The first-level ECU 300a is used to collect the magnetoelectric speed signal, convert the collected magneto-electric speed signal into a Hall speed signal and send it to its own MCU, and simultaneously send it to the adjacent second-level ECU 300b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com