Process for sizing high-count and high-density double-woven fabric

A double-layer fabric, high-count and high-density technology is applied in the field of weaving of clothing fabrics, which can solve the problems of technical difficulties, sizing difficulties, and weaving difficulties, and achieve the effects of improving production efficiency, soft air permeability, and soft hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) Put the prepared slurry formula in a volume of 1m 3 Add water to make it reach the rated water level. The main shaft speed of the pulping barrel is 900rpm, and keep it at a cooking temperature of 90°C and a steam pressure of 0.15Mpa for 5 minutes, and then turn on the small steam for 12 minutes.

[0015] (2) Adopt the following slurry formula: 25kg of polyvinyl alcohol, 25kg of esterified starch, 40kg of phosphate ester starch, 8kg of solid acrylic acid, 2.5kg of wax flakes, and 1.5kg of antistatic agent.

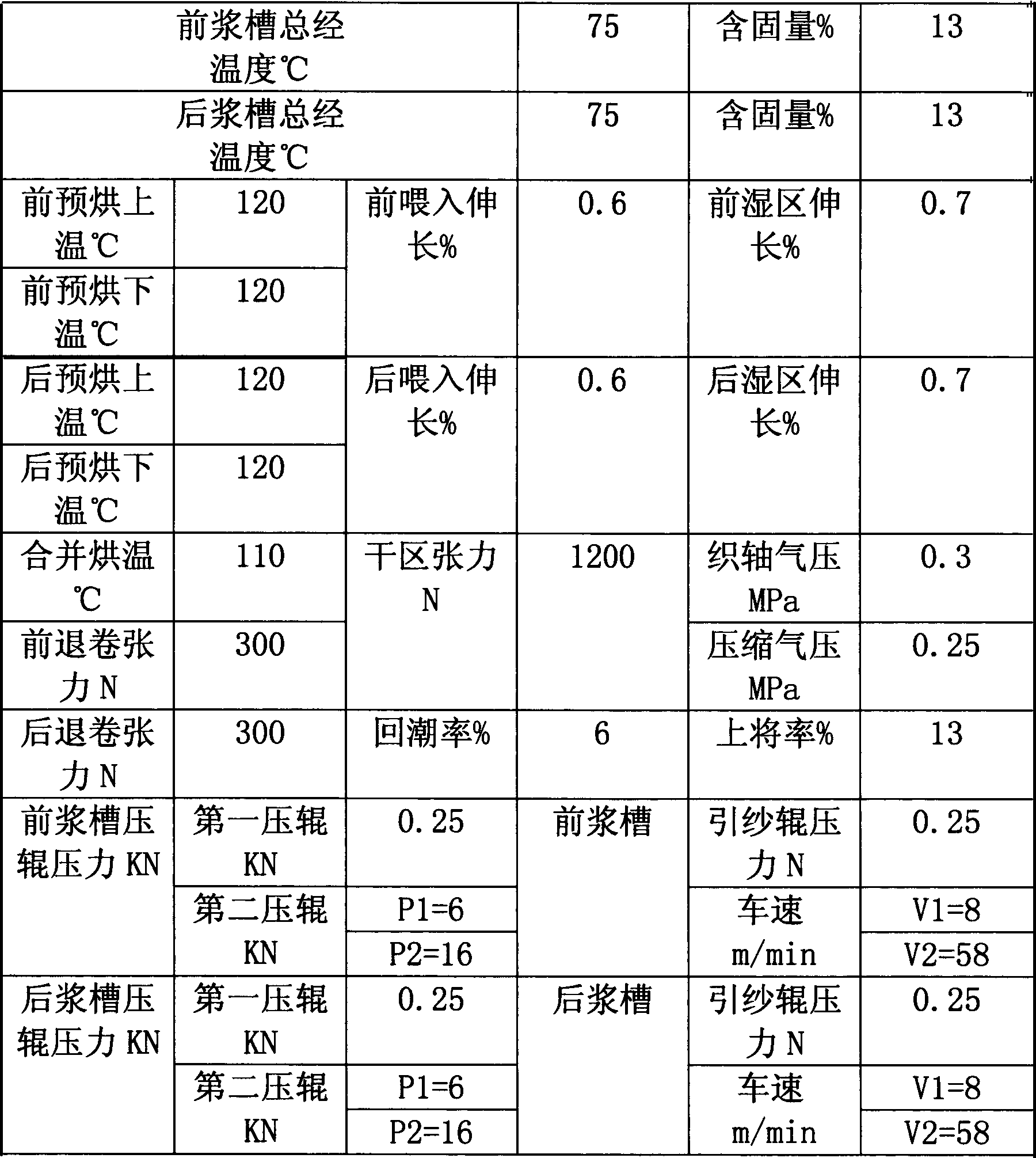

[0016] (3) According to the sizing process parameters of the sizing machine in Table 1, sizing the high-count and high-density yarn on the machine.

[0017] Table 1 Sizing process parameters of sizing machine

[0018]

Embodiment 2

[0020] (1) Put the prepared slurry formula in a volume of 1m 3 Add water to make it reach the rated water level. The main shaft speed of the pulping barrel is 960rpm, and keep it at the cooking temperature of 100°C and the steam pressure of 0.20Mpa for 8 minutes, and then turn on the small steam for 16 minutes.

[0021] (2) The following slurry formula is adopted: 30kg of polyvinyl alcohol, 30kg of esterified starch, 45kg of phosphate ester starch, 10kg of solid acrylic acid, 3kg of wax flakes, and 2kg of antistatic agent.

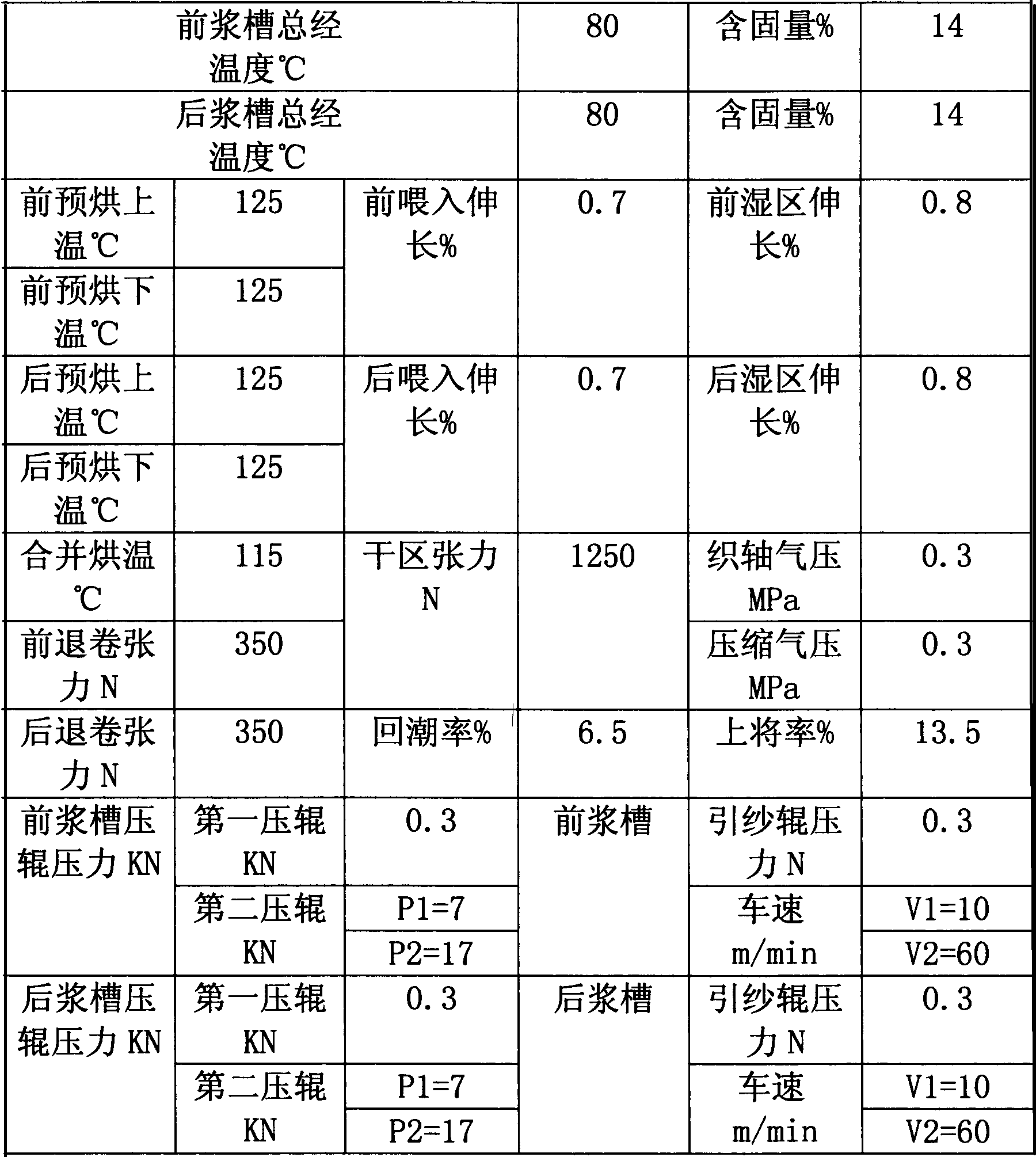

[0022] (3) According to the sizing process parameters of the sizing machine in Table 2, sizing the high-count and high-density yarn on the machine.

[0023] Table 2 Sizing process parameters of sizing machine

[0024]

Embodiment 3

[0026] (1) Put the prepared slurry formula in a volume of 1m 3 Add water to make it reach the rated water level. The main shaft speed of the pulping barrel is 1000rpm, and keep it under the temperature of 110℃ and the steam pressure of 0.25Mpa for 10min, and then turn on the small steam for 20min.

[0027] (2) The following slurry formula is adopted: 35kg of polyvinyl alcohol, 35kg of esterified starch, 50kg of phosphate ester starch, 12kg of solid acrylic acid, 3.5kg of wax flakes, and 2.5kg of antistatic agent.

[0028] (3) According to the sizing process parameters of the sizing machine in Table 3, sizing the high-count and high-density yarn on the machine.

[0029] Table 3 sizing process parameters of sizing machine

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com