Yarn lubricating device

A lubricating device and yarn technology, applied in textiles and papermaking, liquid/gas/steam textile material processing, textile material processing, etc., can solve problems affecting the quality of weaving finished products, inconvenient cleaning, high fuel consumption, etc., to achieve The effect of reducing work tasks, saving costs, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

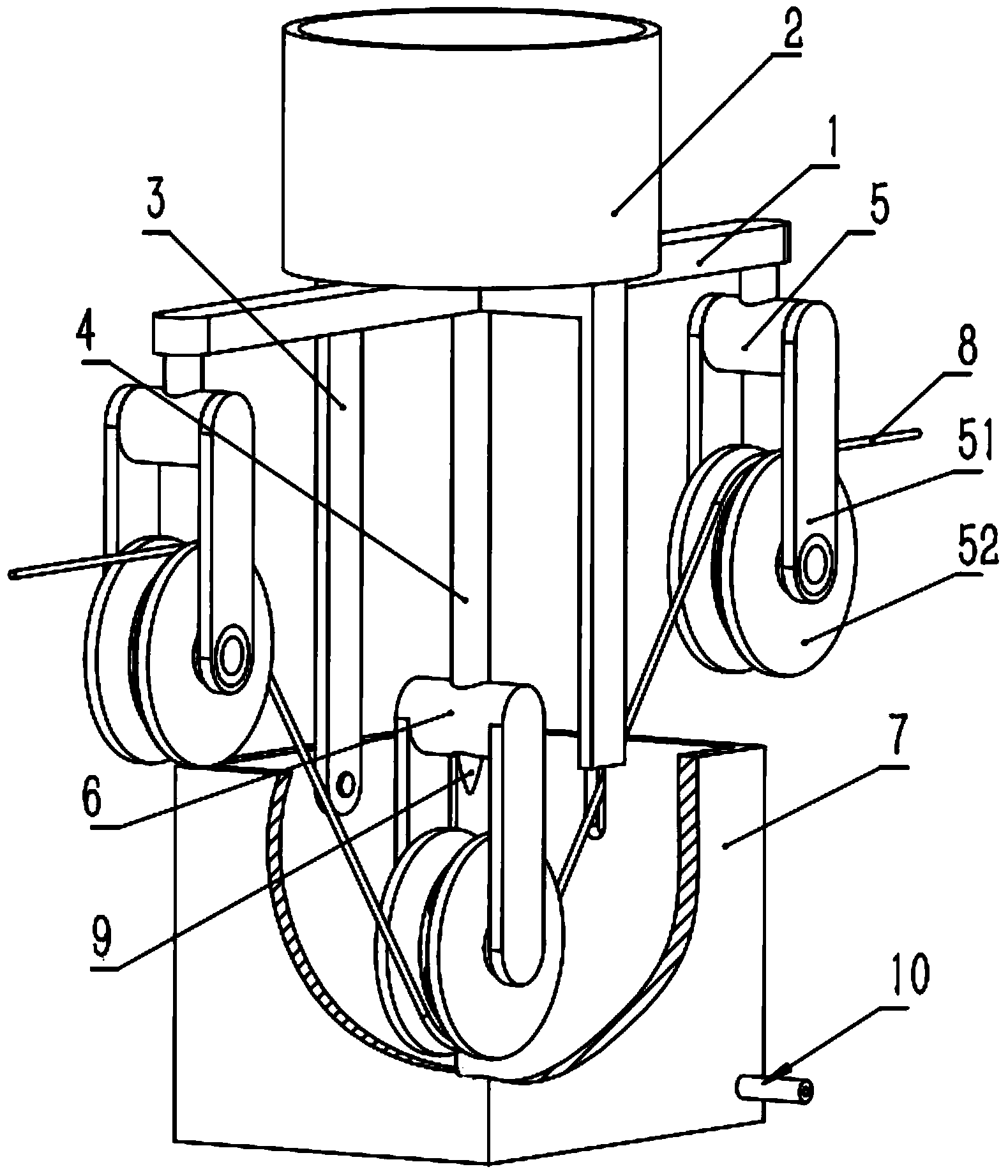

[0013] Example: see figure 1 As shown, a yarn lubricating device includes a cross-shaped support 1, an oil storage tank 2 is provided on the support 1, driven guide wheels 5 are provided at the left and right ends of the support 1, and support rods are fixedly connected at the front and rear ends of the support 1 3. The lower end of the support rod 3 is fixedly connected to the oil receiving tank 7, and the oil receiving tank 7 is equipped with a capstan 6 mechanism, and the driving guide wheel 6 is plugged into the lower end of the round pipe 4, and the lower end of the round pipe 4 is formed with an oil leakage nozzle 9 , The oil leak nozzle 9 is located above the guide wheel 52 of the driving guide wheel 6; the upper end of the round pipe 4 passes through the bracket 1 and communicates with the oil storage tank 2.

[0014] The driving guide wheel 6 and the driven guide wheel 5 are composed of an inverted U-shaped fixed mount 51 and a guide wheel 52. The upper end of the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com