Nitrile rubber composite capable of improving mechanical property

A technology of nitrile-butadiene rubber and composition is applied in the field of polymer material preparation, which can solve the problems of inability to rebound in place, easy aging of rubber, unstable tensile strength and elongation at break, etc., and achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

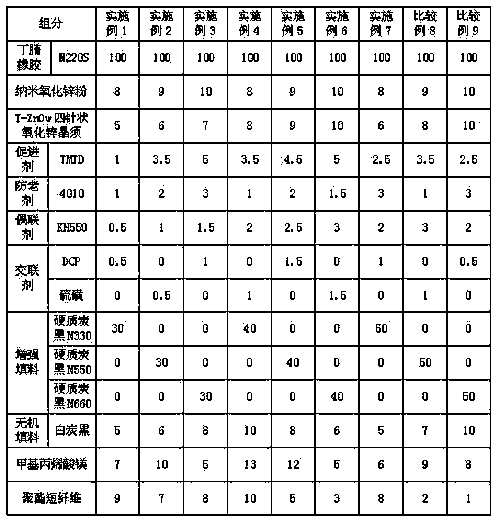

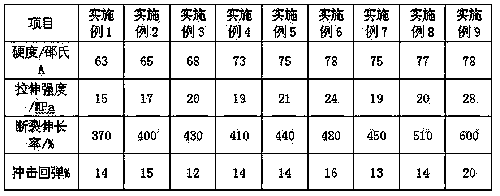

[0022] A nitrile rubber composition with improved mechanical properties. The composition uses nitrile rubber as the main material and 100 parts by weight of nitrile rubber. The composition includes:

[0023] Nitrile rubber 100 parts,

[0024] Accelerator 1-5 parts,

[0025] Anti-aging agent 1-3 parts,

[0026] 8-10 parts of nano zinc oxide powder,

[0027] 0.5-1.5 parts of crosslinking agent,

[0028] Reinforcing filler 30-60 parts,

[0029] 5-10 parts of inorganic filler,

[0030] T-ZnOw four-needle zinc oxide whiskers 0.5-10 parts,

[0031] 0.2-5 parts of coupling agent,

[0032] 5-15 parts of magnesium methacrylate,

[0033] 1-10 parts of polyester staple fiber.

[0034] The composition of the nitrile rubber includes 35-41% acrylonitrile by weight, and the Mooney viscosity is 50-56 (ML 1+4 100°C).

[0035] The models of the nitrile rubber are N220S, N230S and N240S.

[0036] The accelerator is one or a mixture of two or more of TMTD, CZ, and M.

[0037] The antioxidant is one or a mixture of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com